Improved Brandon steam seal suitable for low-load working condition

A low-load, improved technology for leak prevention, engine components, machines/engines, etc., to address issues such as reduced economy and increased seal failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

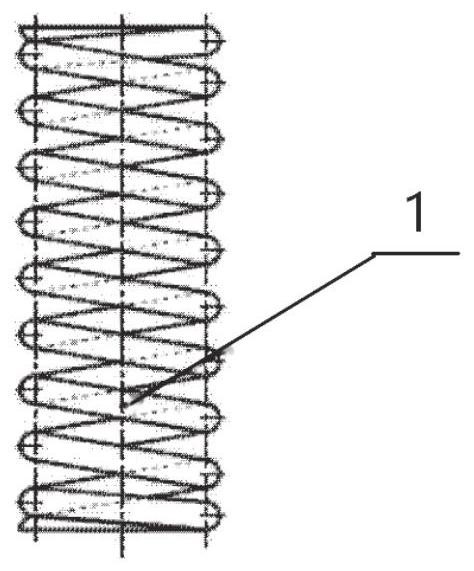

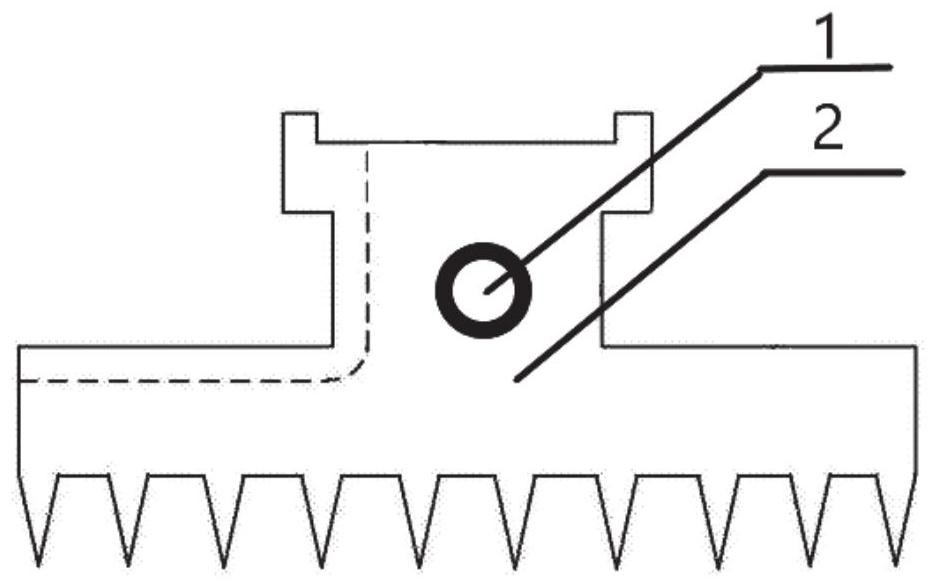

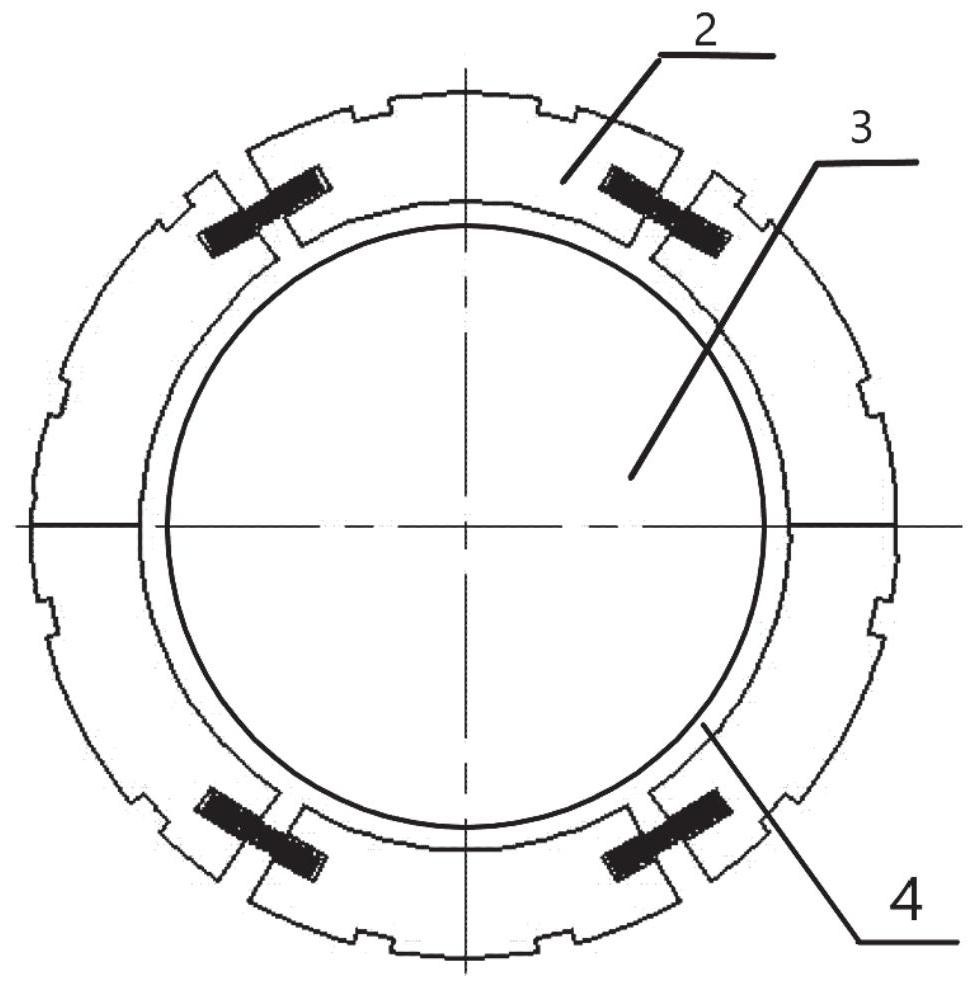

[0024] As an example, such as Figure 1-3 As shown, the improved Braden steam seal suitable for low-load working conditions, by adjusting the length of the spring in the steam seal structure and increasing the installation gap of the steam seal, the closing time of the steam seal is advanced to meet the requirements of the coal-fired generator set in the deep The requirement of long-term low-load operation under the background of peak regulation improves the econ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com