Memory, dangerous chemical tank area safety risk early warning method and device and apparatus

A technology of hazardous chemicals and safety risks, applied in the field of industrial control, can solve problems such as broad-spectrum management and supervision, safety risks of unsuitable hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

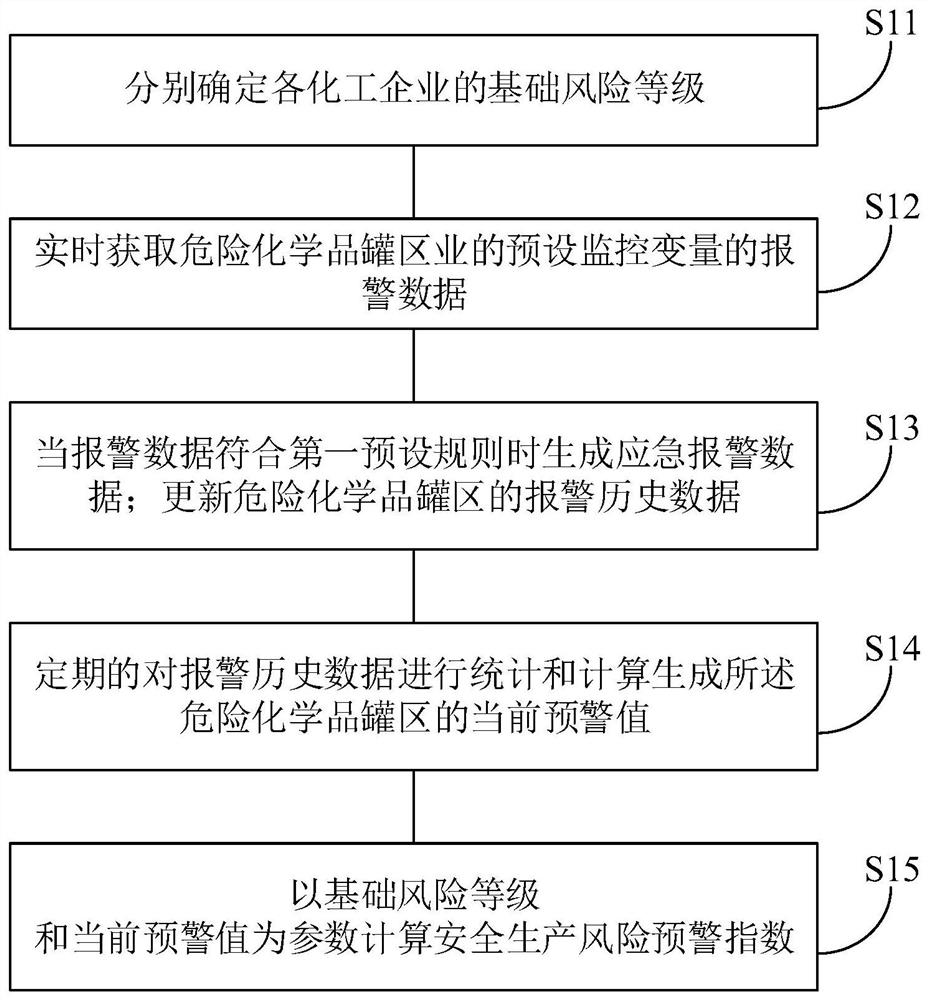

[0059] In order to improve the timeliness and effectiveness of the supervisory department on the safety production risk supervision of chemical enterprises, such as figure 1 As shown, an embodiment of the present invention provides a dangerous chemical tank area safety risk early warning method, including steps:

[0060] S11. Determine the basic risk level of each chemical enterprise based on the classification scores of the major hazard sources of hazardous chemicals in the hazardous chemical tank farms of each chemical enterprise;

[0061] The application scenario of the embodiment of the present invention may be that the government's supervision department establishes a data communication connection with all dangerous chemical tank farms in its jurisdiction based on the Internet, and obtains the reported data of each dangerous chemical tank farm.

[0062] In practical application, according to the State Administration of Work Safety No. 40 "Interim Provisions on the Supervi...

Embodiment 2

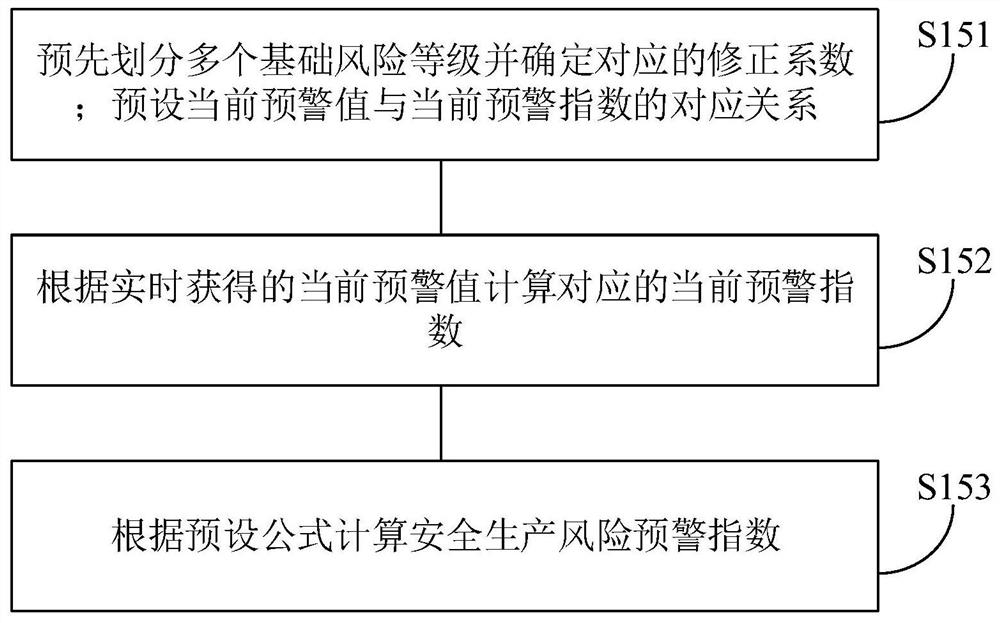

[0101] In order to obtain a more intuitive and accurate safety production risk early warning index, in the embodiment of the present invention, on the basis of Embodiment 1, the method of obtaining the safe production risk early warning index is further optimized, as follows figure 2 shown, including:

[0102] S151. Divide the scores of the classification of major hazard sources of hazardous chemicals into multiple basic risk levels in advance, and determine the corresponding correction coefficients according to the basic risk levels; preset the current warning value and the multiple current warning levels Current warning index T R corresponding relationship;

[0103] In practical applications, as shown in Table 2, the scores of major hazard sources of hazardous chemicals can be divided into four basic risk levels and their corresponding correction coefficients γ R ;

[0104] Table 2:

[0105] serial number R Maj_hazard value

Basic Risk Level Correction...

Embodiment 3

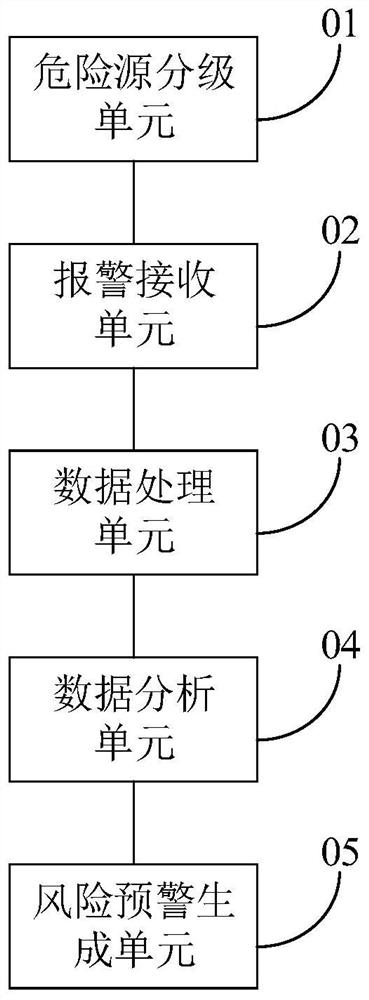

[0116] On the other side of the embodiment of the present invention, a safety risk early warning device for dangerous chemical tank area is also provided, image 3 It shows a schematic structural diagram of a safety risk early warning device for a dangerous chemical tank area provided by an embodiment of the present invention, and the safety risk early warning device for a dangerous chemical tank area is compatible with figure 1 and figure 2 The device corresponding to the safety risk early warning method for the hazardous chemical tank area described in the first embodiment, that is, realized by means of a virtual device figure 1 and figure 2 In the corresponding embodiment of the dangerous chemical tank farm safety risk early warning method, each virtual module constituting the hazardous chemical tank farm safety risk early warning device can be executed by electronic equipment, such as network equipment, terminal equipment, or server. Specifically, the dangerous chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com