Low-voltage-drop Schottky rectifier tube

A rectifier, low-voltage drop technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems affecting the forward conduction current of Schottky rectifiers, large forward voltage drop, poor performance of Schottky rectifiers, etc. , to achieve the effect of improving the weakening effect, reducing the forward voltage and increasing the forward current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

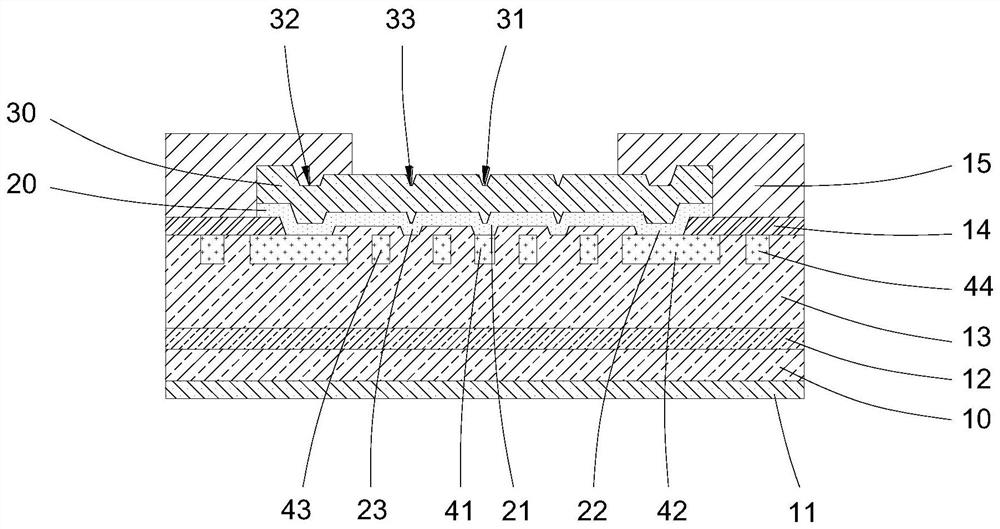

[0021] refer to figure 1 .

[0022] The embodiment of the present invention discloses a low-voltage drop Schottky rectifier, which includes an n-type substrate 10, a cathode metal layer 11 is arranged under the n-type substrate 10, and n-type buffer layers are sequentially stacked on the n-type substrate 10 along the longitudinal direction. Layer 12 and n-type drift layer 13, the n-type drift layer 13 is provided with a Schottky barrier metal layer 20 and an annular first passivation layer 14, and the center of the annular first passivation layer 14 is formed with a Schottky The opening of the base barrier metal layer 20, the edge of the Schottky barrier metal layer 20 is stacked on the first passivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com