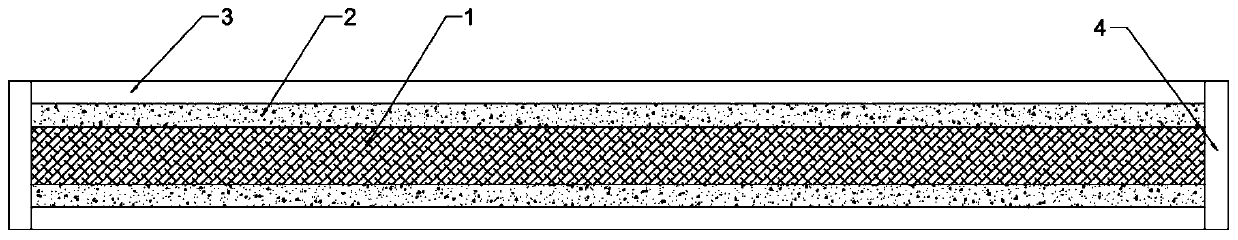

A polymer sound-absorbing composite panel and its manufacturing method

A manufacturing method and polymer technology, applied in chemical instruments and methods, layered products, wood-layered products, etc., can solve the problems of disappearance, reduced sound-absorbing ability, weak induction ability, etc., and achieve high-frequency sound wave reduction ability. , Increase the weakening ability, the effect of strong induction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

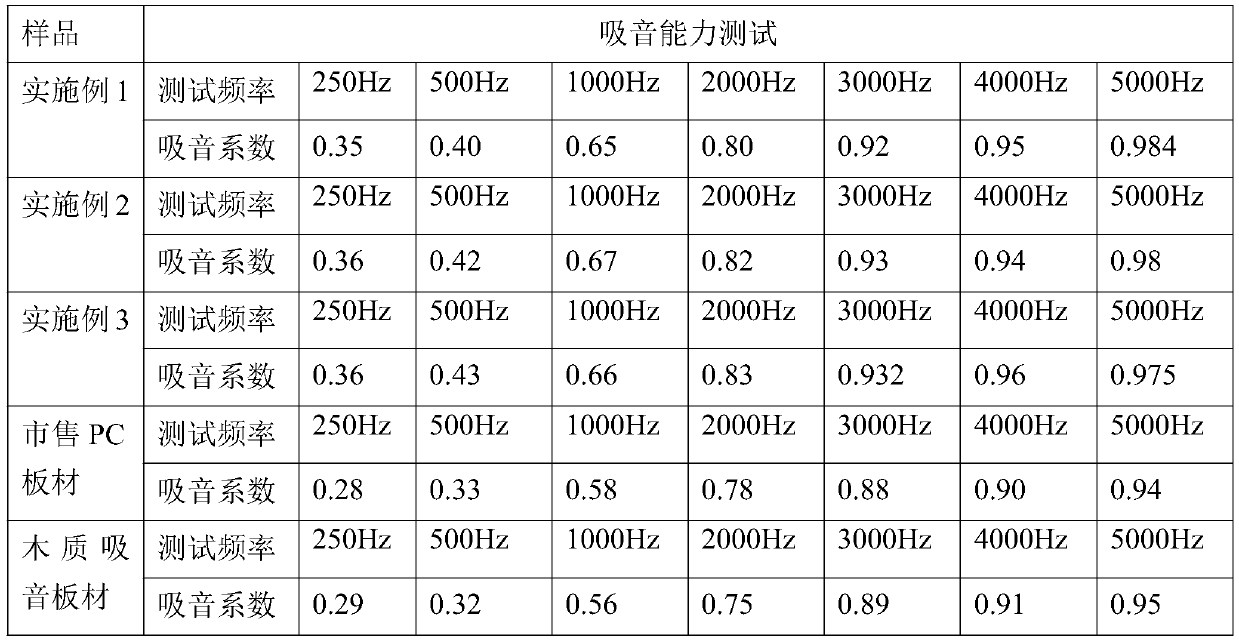

Embodiment 1

[0032] Polymer foam layer material preparation: 100 parts of polyvinyl chloride, 15 parts of porous ceramic particles, 15 parts of foaming agent (selected formula: 3 parts of phosphoric acid, 5 parts of oxalic acid, 7 parts of p-azodicarbonamide), magnesium-aluminum layered 25 parts of double metal hydroxide, 2 parts of crosslinking agent, 25 parts of EVA particles, 40 parts of melt-blown fiber, 5 parts of industrial hydrogen peroxide, and 15 parts of magnesium chloride.

[0033] Mixed airgel layer material preparation: 80 parts of polyurea airgel powder, 40 parts of polyurethane airgel powder, 40 parts of wood micropowder, 100 parts of phenolic resin.

[0034] Its polymer foam layer manufacturing process is as follows:

[0035] (6) Magnesium chloride is heated to 70-80 degrees Celsius after being dissolved in water to form a magnesium chloride solution;

[0036] (7) foaming agent, gas generating agent, crosslinking agent and magnesium chloride solution are uniformly mixed to...

Embodiment 2

[0047] Preparation of polymer foam layer materials: 80 parts of polyvinyl chloride, 25 parts of porous ceramic particles, 8 parts of foaming agent (selected formula: 1 part of phosphoric acid, 2 parts of oxalic acid, 5 parts of p-azodicarbonamide), 20 parts of magnesium hydroxide parts, 3 parts of cross-linking agent, 15 parts of EVA particles, 60 parts of melt-blown fiber, 2 parts of aluminum powder, and 20 parts of magnesium chloride.

[0048] Mixed airgel layer material preparation: 100 parts of polyurea airgel powder, 70 parts of polyurethane airgel powder, 30 parts of wood micropowder, 70 parts of epoxy resin.

[0049] The reinforcement layer chooses laminated wood boards.

[0050] All the other procedures are the same as in Example 1.

Embodiment 3

[0052] Preparation of polymer foam layer materials: 90 parts of polyvinyl chloride, 20 parts of porous ceramic particles, 12 parts of foaming agent (the selected formula is: 2 parts of phosphoric acid, 4 parts of oxalic acid, 6 parts of p-azodicarbonamide), 22 parts of aluminum hydroxide parts, 2.5 parts of cross-linking agent, 20 parts of EVA particles, 50 parts of melt-blown fiber, 4 parts of aluminum paste, and 20 parts of magnesium chloride.

[0053] Mixed airgel layer material preparation: 60 parts of polyurea airgel powder, 55 parts of polyurethane airgel powder, 35 parts of wood micropowder, 85 parts of phenolic resin.

[0054] Aluminum plate is selected as reinforcement layer.

[0055] All the other procedures are the same as in Example 1.

[0056] It is worth mentioning that the smaller the diameter of the melt-blown fiber, the stronger the vibration effect, the stronger the sound consumption ability, and the better the sound insulation effect. Therefore, the diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com