Combined automatic adjustment sound barrier

An automatic adjustment, sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of sound barrier absorption, complex noise, etc., to achieve the effect of improving the absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through specific implementations:

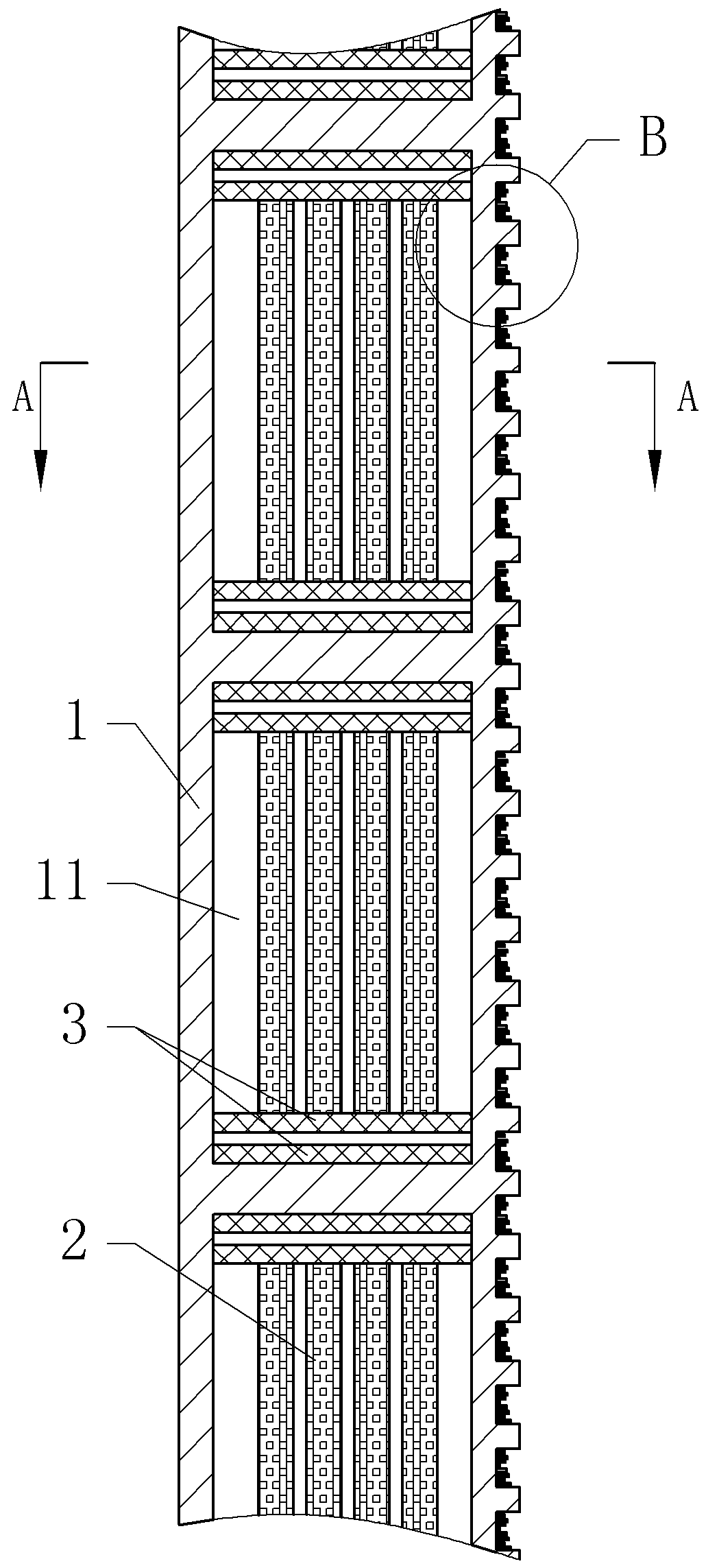

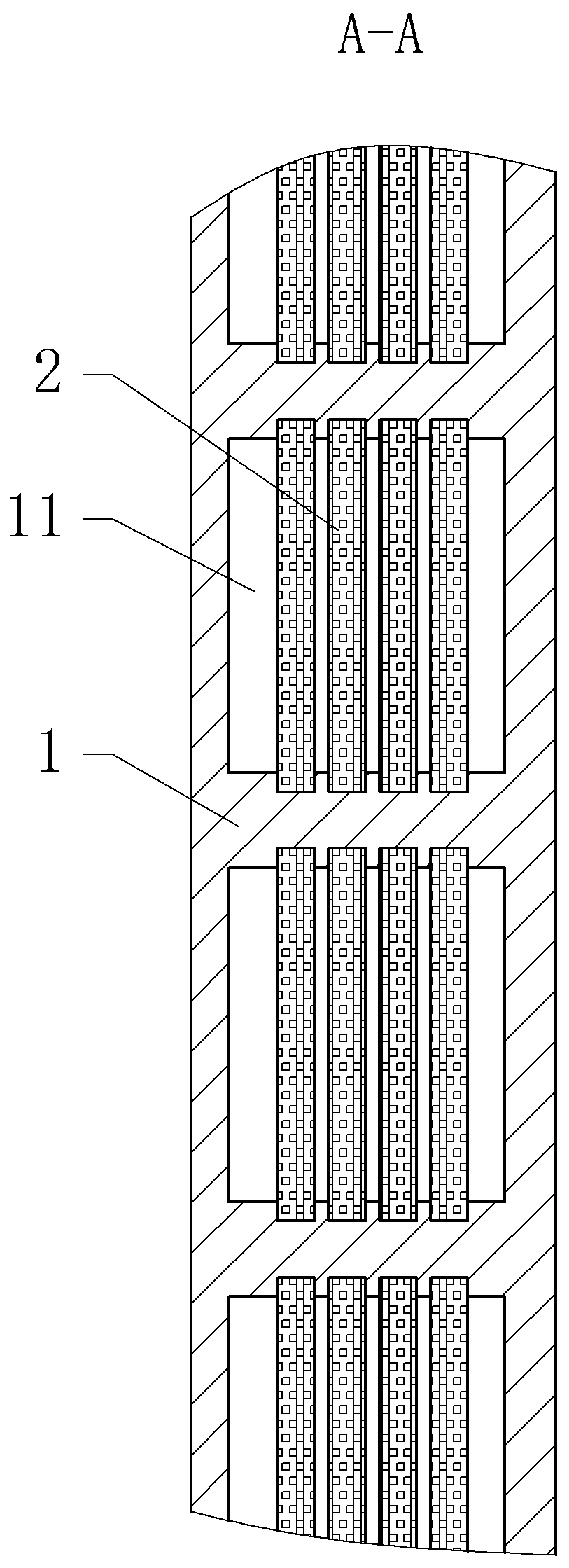

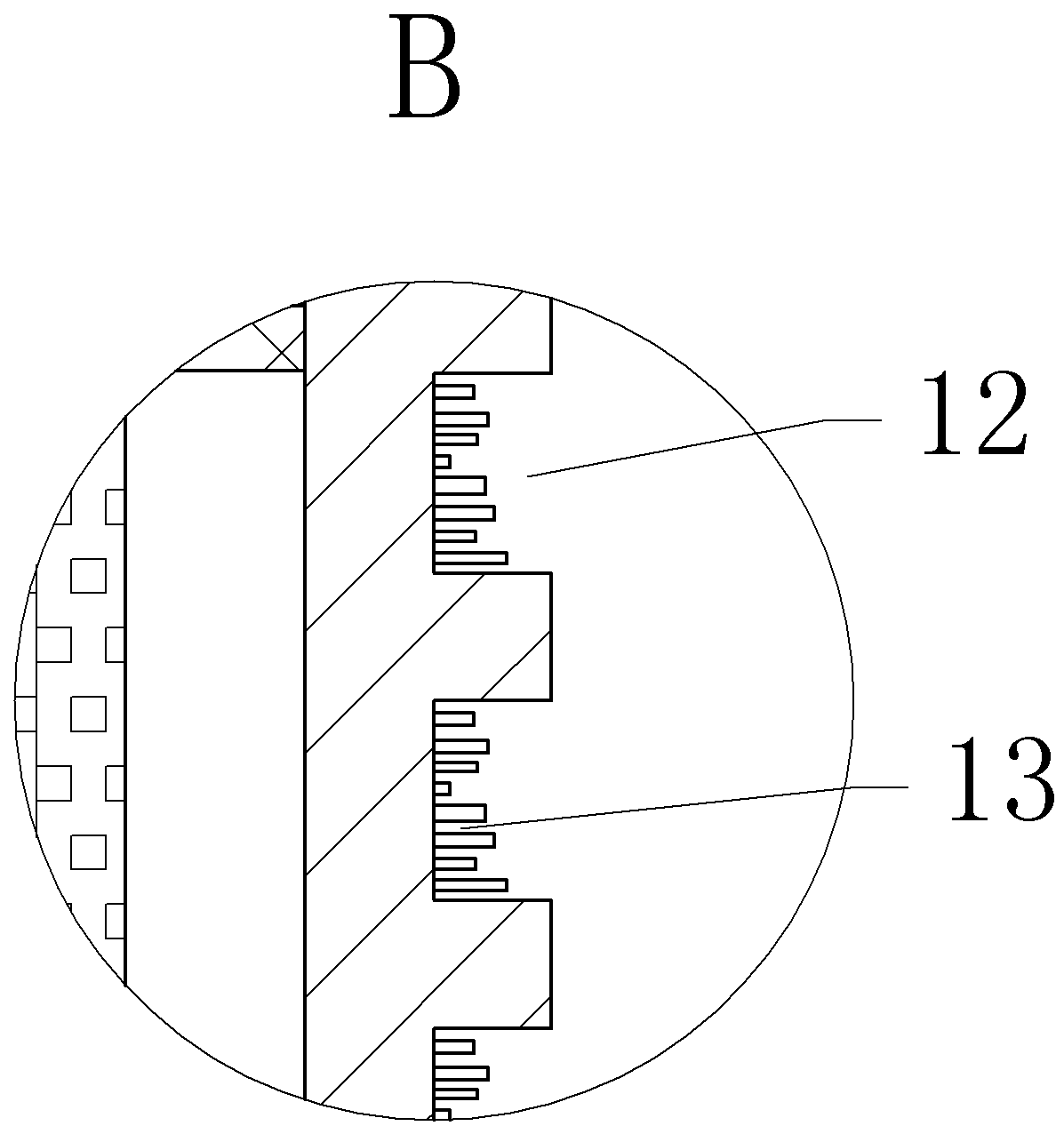

[0020] The reference signs in the drawings of the specification include: soundproof main body 1, sound absorbing unit 2, electromagnet 3, cavity 11, groove 12, and slit 13.

[0021] Such as figure 1 , figure 2 As shown, the combined self-adjusting sound barrier of this embodiment includes a soundproof body 1, a control unit, and a number of sound-absorbing units 2. The sound-proof body 1 is provided with a number of square cavities 11, and the sound-absorbing unit 2 is made of multiple layers of porous materials. And there is a 5mm gap between adjacent porous materials. The porous material in this embodiment is foamed plastic. The sound-absorbing unit 2 is arranged in the cavity 11, and a notch is provided on the side wall of the cavity 11, and the notch clamps and fixes the sound-absorbing unit 2 in the cavity 11; the sound-absorbing unit and the side wall of the cavity 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com