A seed belt preparation device for directional sowing of corn

A technology for preparing a device and a seed belt, applied in the field of agricultural machinery, can solve problems such as work efficiency needs to be improved, and achieve the effects of saving dosage, reducing complexity and improving bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

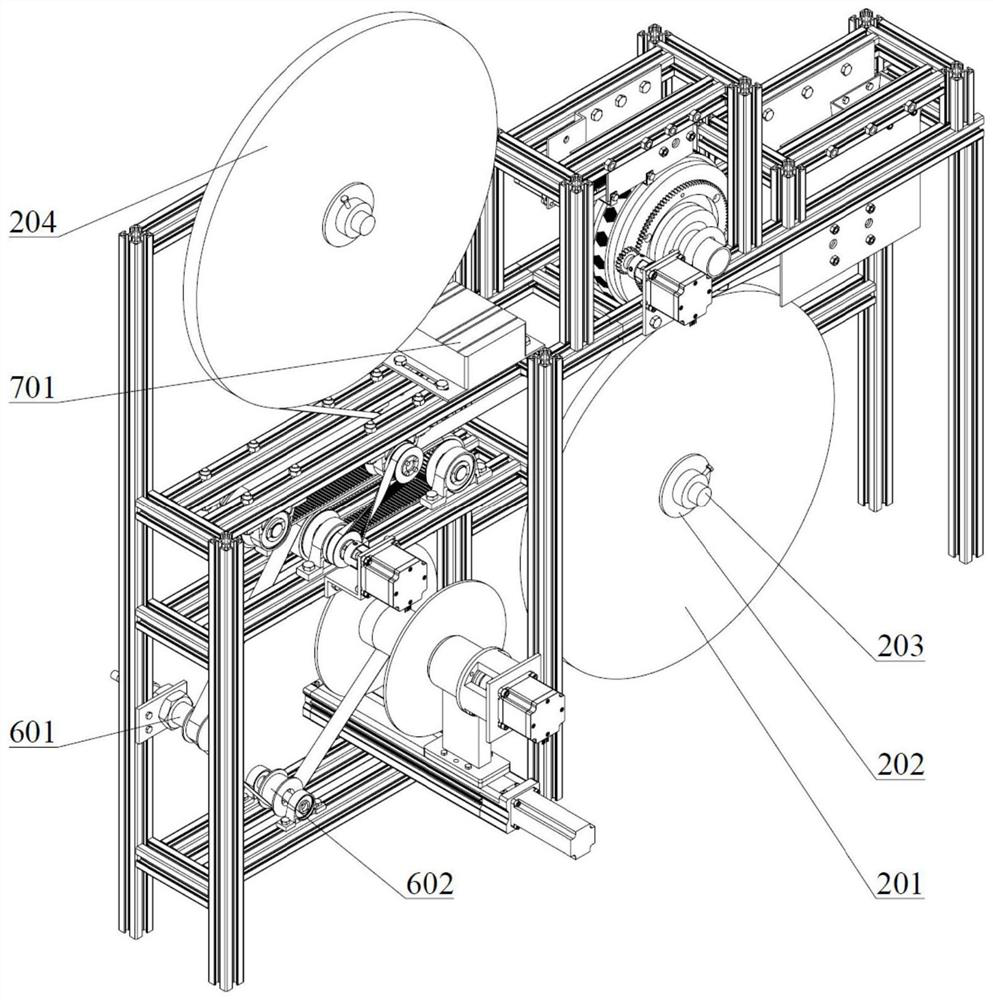

[0078] The following is attached Figure 1-9 The present invention is described in further detail.

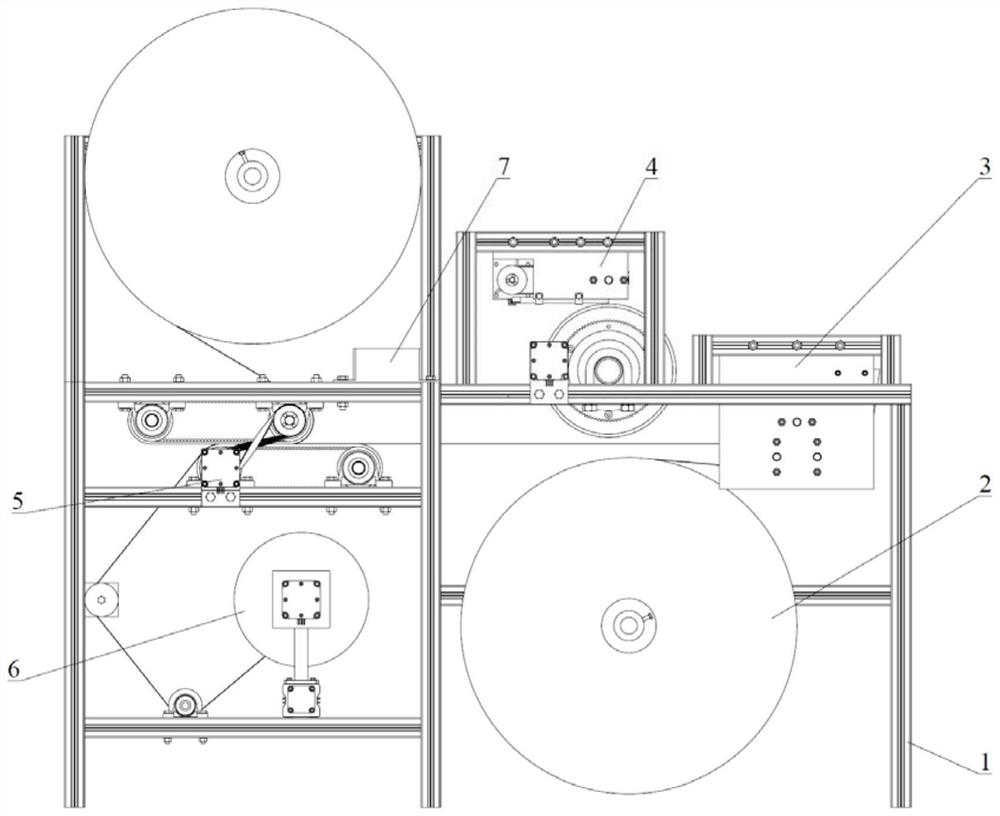

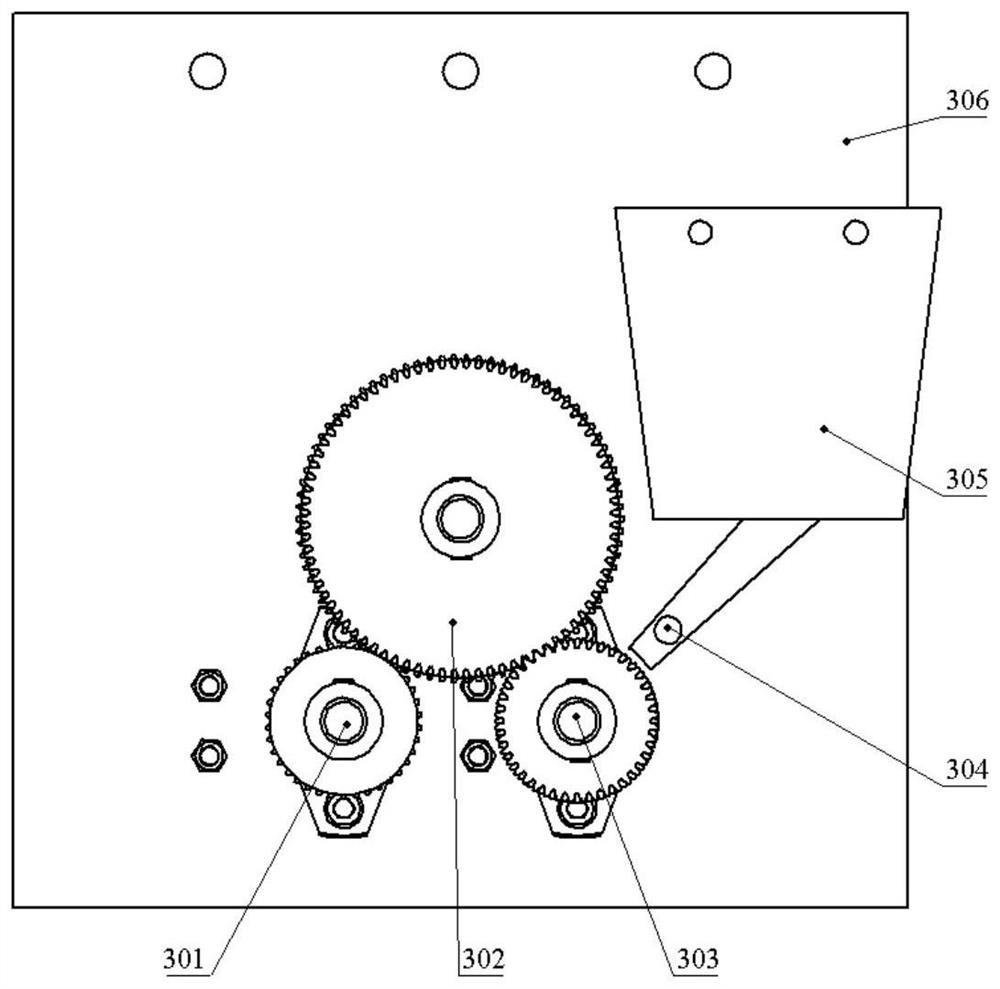

[0079] like figure 1 , figure 2 As shown, a seed belt preparation device for directional sowing of corn comprises a working frame 1, a paper tape unwinding mechanism 2, a gluing mechanism 3, a directional zero-speed seeding mechanism 4, an upper and lower paper tape bonding mechanism 5, Winding mechanism 6 and control system 7;

[0080] The working frame 1 is spliced by multiple aluminum profiles;

[0081] The paper tape unwinding mechanism 2 includes: a lower paper tape 201, two material blocking discs 202, two optical axes I 203 and an upper paper tape 204;

[0082] The upper paper tape 204 is concentrically installed on one of the optical axes I 203 through the material blocking plate 202, and one of the optical axes I 203 is installed on the upper left of the working frame 1, and the lower paper tape 201 is concentrically installed on the On another optical axis I 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com