Atomizer capable of preventing tar leakage and tar absorption and application of atomizer

An atomizer and oil leakage prevention technology, which is applied in the field of electronic cigarettes, can solve the problems of oil leakage of smoking equipment, smoke easily exposed to cold, and consumers absorb oil, etc., and achieve the effect of improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

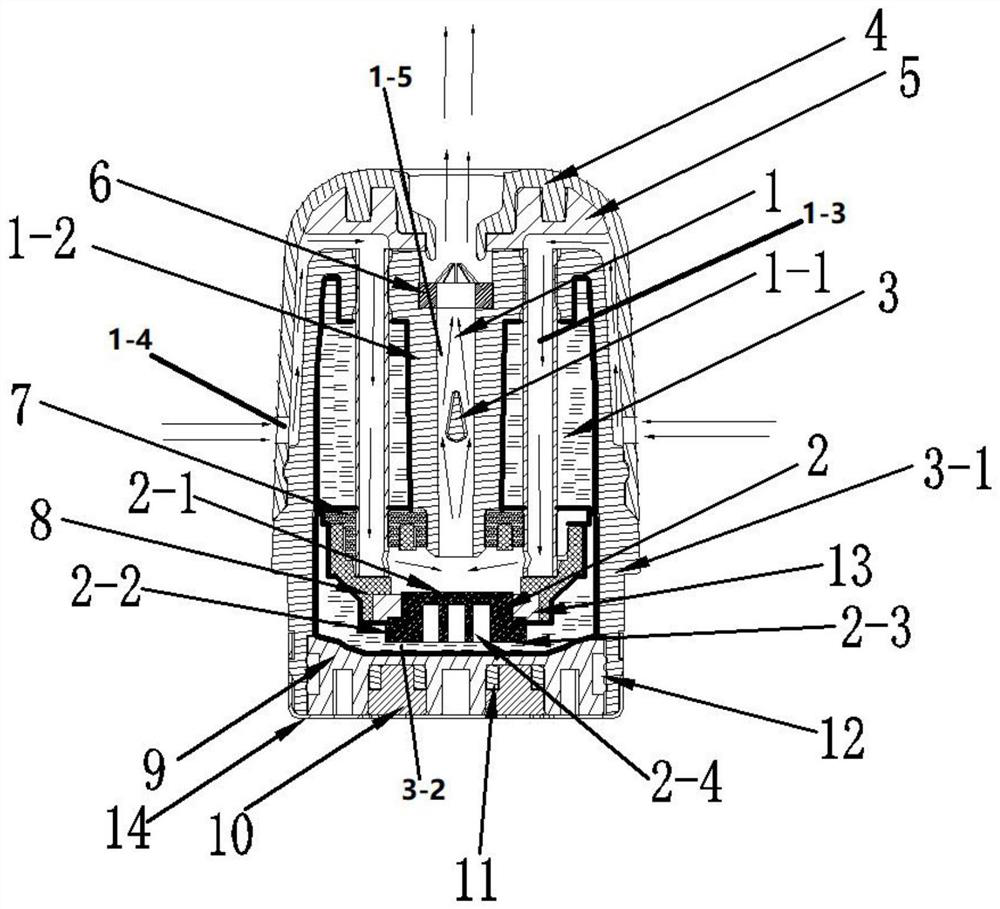

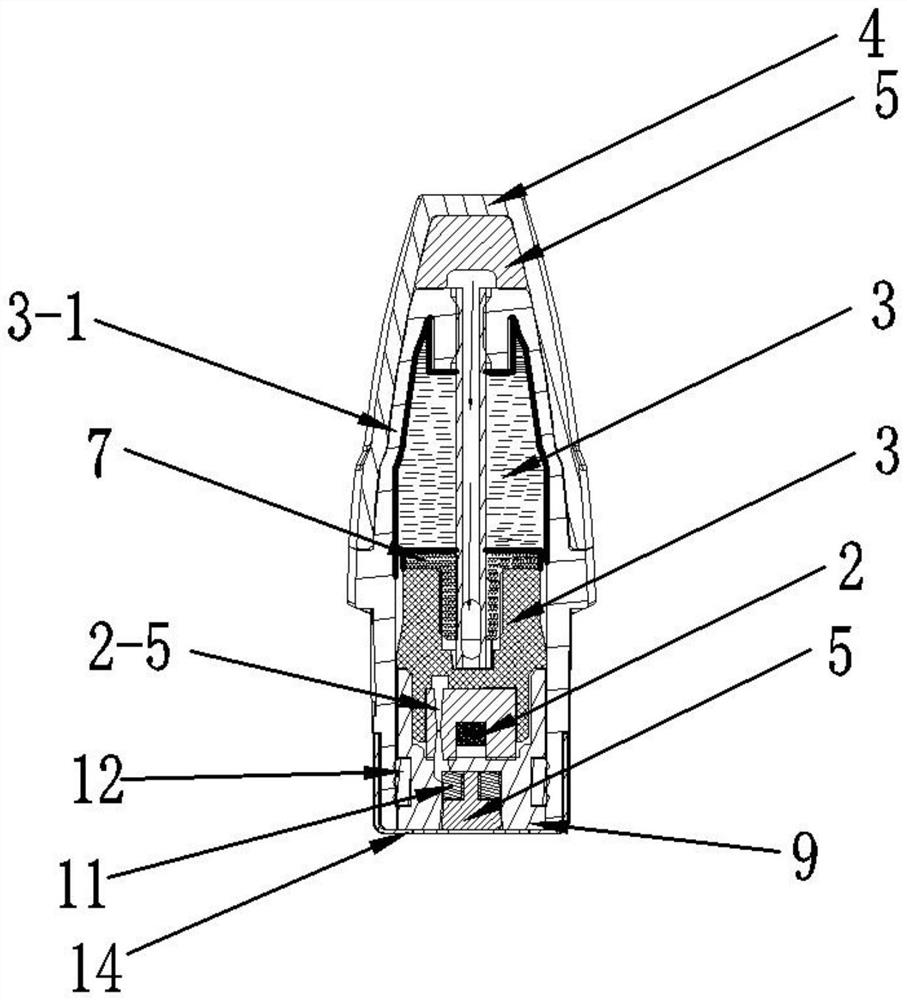

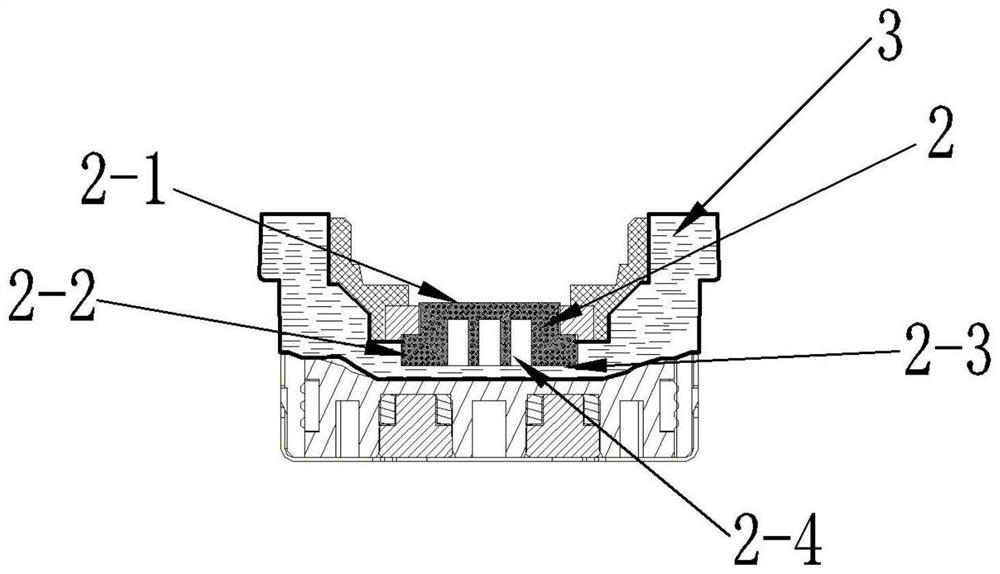

[0048] Such as Figure 1-4 The oil-leakage-proof and oil-absorbing atomizer shown and described in the above summary of the invention includes the following components: atomizing core 2, oil storage bin 3, mouthpiece 4, mouthpiece sealing silicone part 5, one-way valve 6, air passage Sealing silicone part 7, atomizing core fixing bracket 8, internal fixing bracket 9, energized electrode 10, electrode sealing silicone part 11, oil storage tank sealing silicone part 12, ceramic heat insulating silicone part 13, fixing seat 14.

[0049] The installation relationship of the above components is as follows:

[0050] The outermost layer of the atomizer is a detachably connected mouthpiece 4 and a fixing seat 14 from top to bottom. The mouthpiece sealing silicone part 5 is arranged in the mouthpiece 4 to realize the sealing effect when the mouthpiece 4 is connected with other parts.

[0051] The inside of the atomizer is provided with an oil storage bin 3, in which smoke oil is stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com