Multifunctional full-automatic rice steaming machine

A fully automatic, rice steaming machine technology, applied in the field of kitchen utensils, can solve the problems of automatic rice washing, difficulty, and not suitable for home use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

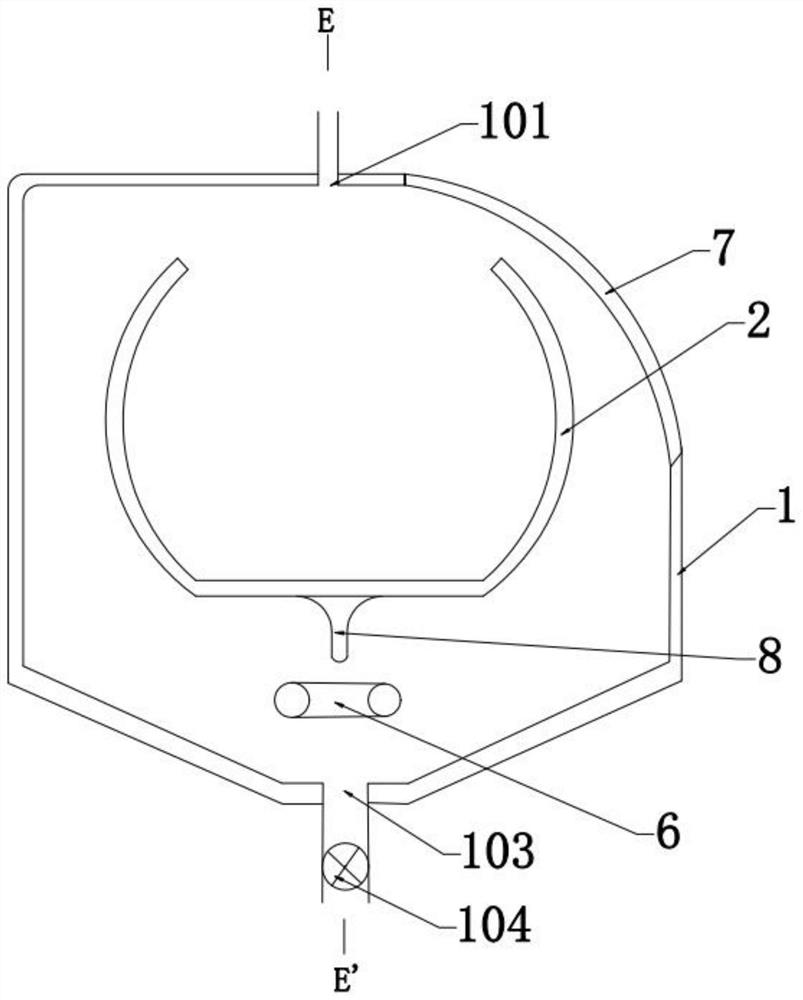

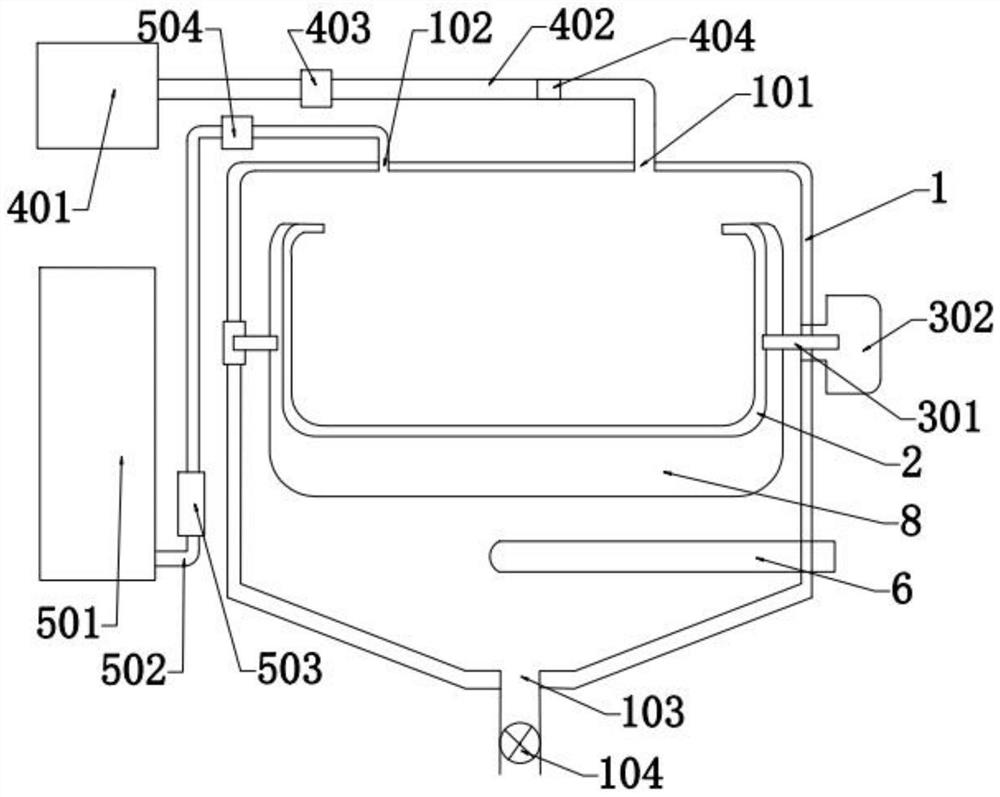

[0028] Such as figure 1 , 2 As shown, a multifunctional automatic rice steamer in this implementation includes: a steaming box 1, an inner pot body 2, a driving device 3, a water injection device and a rice injection device, and the steaming box 1 and the inner pot body 2 are made of stainless steel Made, the steamer 1 is provided with an accommodating space, the two sides of the inner pot body 2 are movably connected in the accommodating space through the driving device 3, and the connecting shaft 301 of the driving device 3 is connected with the rotation center of the inner pot body 2, and the inner pot body Both sides of the body 2 are arc-shaped, the top is open, and the bottom of the pot is a plane. A stirring blade 8 is arranged at the midline of the inner pot body 2, but it is not limited thereto. According to the different structures of the inner pot body 2, it can be Several agitating blades 8 are used together on the outer wall of the pot body 2 to ensure that the c...

Embodiment 2

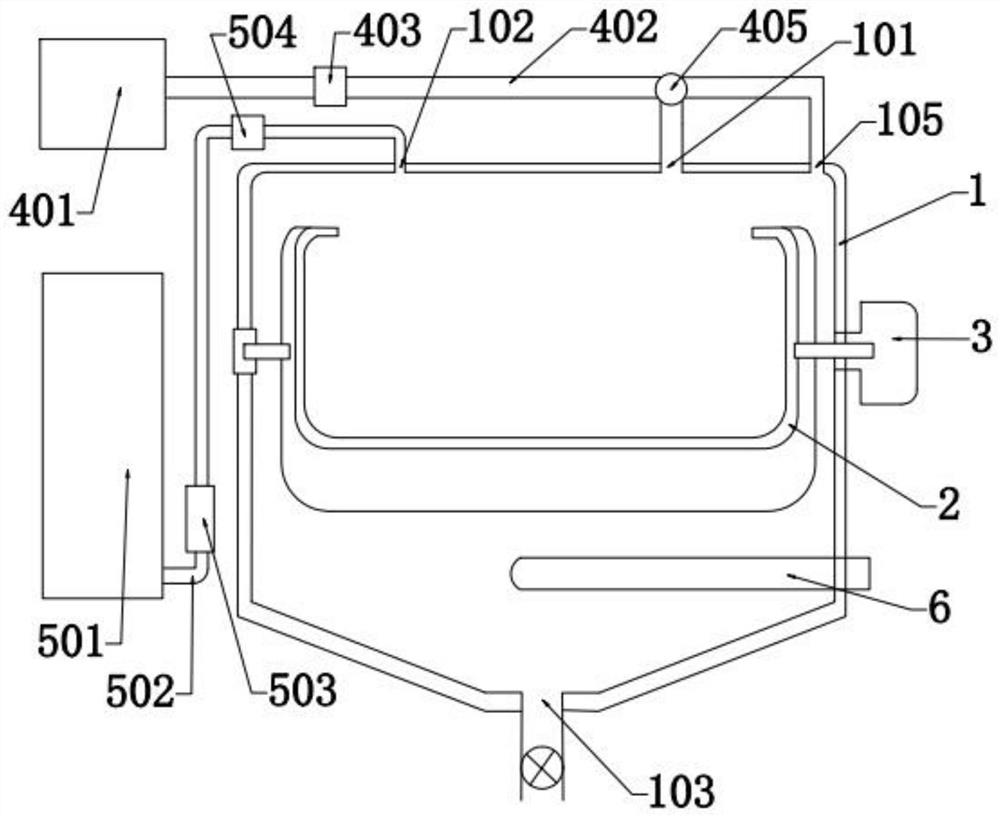

[0041] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that it also includes a second water injection port 105, the second water injection port 105 is arranged on the top of the steam box 1, and is located between the inner pot body 2 and the steam box 1, The first water injection port 101 is located directly above the opening of the inner pot body 2, and the water injection device is respectively connected to the first water injection port 101 and the second water injection port 105 through a three-way valve 405, which can directly control the three-way valve according to the process requirements. The valve 405 selectively injects water into the inner pot body 2 and the steam box 1 without turning the inner pot body 2, and the operation process is simpler and more efficient. But not limited thereto, the second water injection port 105 can also be arranged on the side wall of the steam box 1 and between the inner pot body 2 and the...

Embodiment 3

[0043] Such as Figure 4 , 5 As shown, the difference between this embodiment and the first embodiment is that the heating device includes an electromagnetic heating device, and the electromagnetic heating device is arranged on the bottom outer wall of the steam box 1 . This structure prevents the electric heating rod from being frequently washed by the water flow in the steamer 1, and the stability of the device is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com