Shoe sole cleaning machine

A sole cleaning machine and cleaning technology, which are applied to cleaning equipment, cleaning of boots and shoes, household cleaning devices, etc., can solve the problems of poor water absorption, unsanitary and unsightly appearance of water absorbing pads, and improve cleaning efficiency and cleaning effect. , the effect of dexterity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

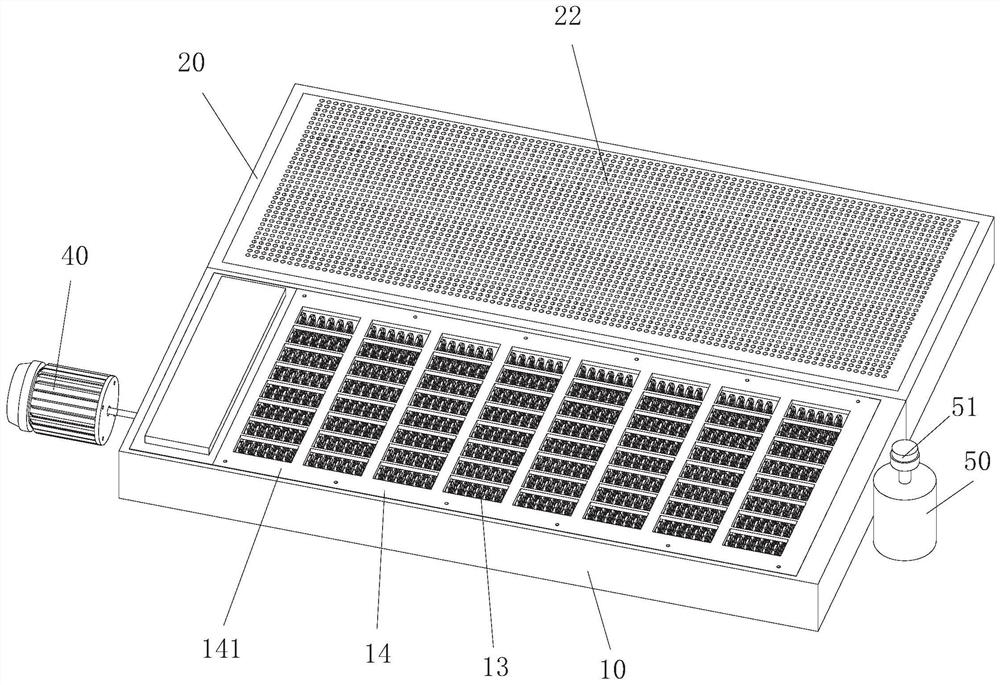

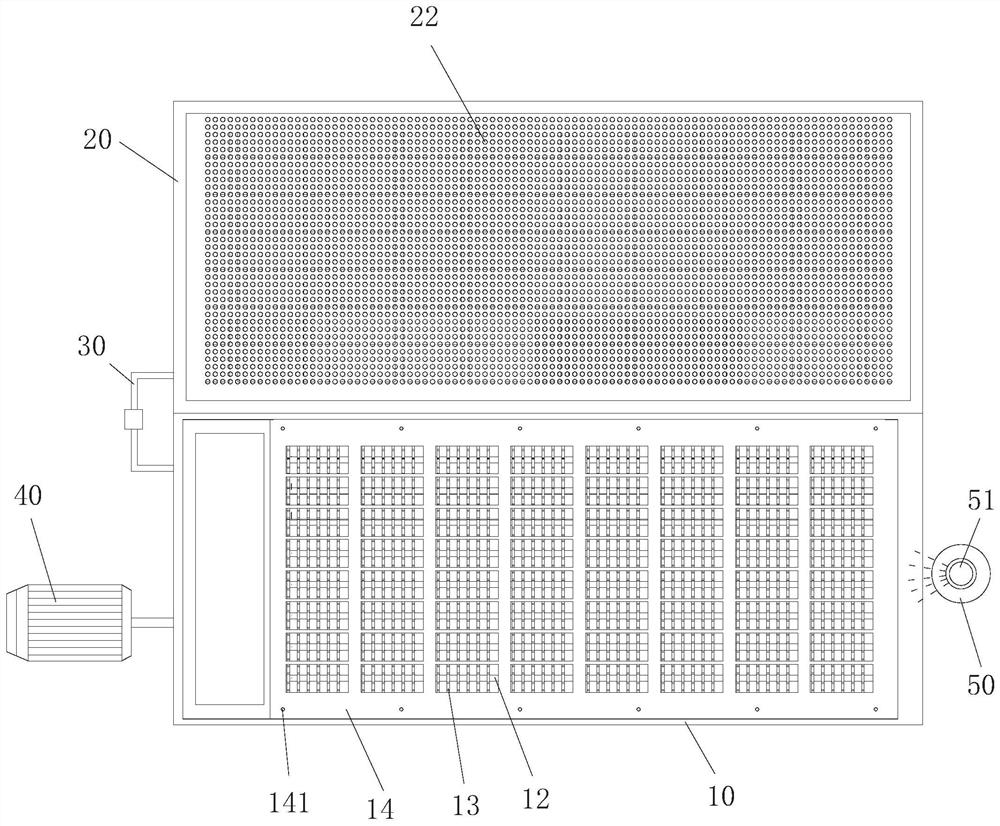

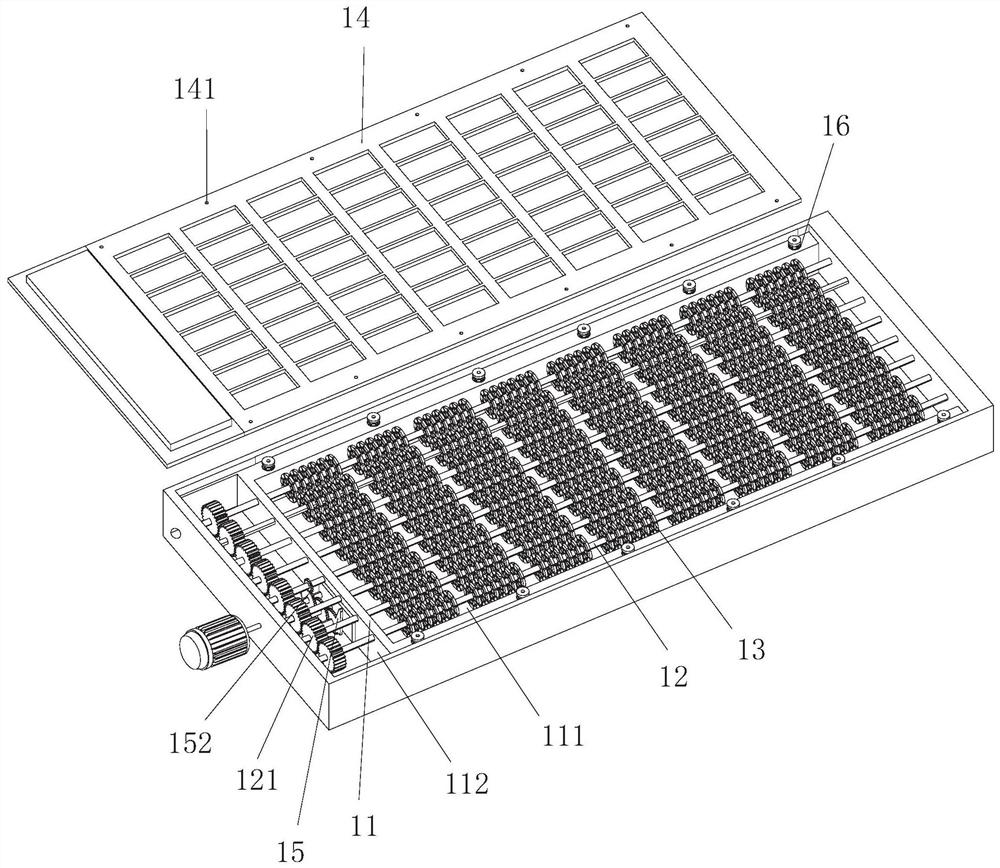

[0051] Such as Figure 1 to Figure 11 As shown, the present invention discloses a shoe sole cleaning machine, which includes a first water tank 10 and a second water tank 20 . The first water tank 10 and the second water tank 20 adopt a separate structure, and the two parts are spliced together to make the mechanism into parts. The product structure is light and handy, convenient for packaging, handling and transportation, and convenient for disassembly and installation.

[0052] The first water tank 10 is positioned at the front of the whole device and plays the role of cleaning the soles. A frame 11 is provided in the first water tank 10 , and the frame 11 is mainly used to provide installation support for internal components of the first water tank 10 . Several rotating shafts 12 are arranged side by side on the frame 11, and several cleaning wheels are evenly arranged and installed on each rotating shaft 12. There is a circle of cleaning brushes 13 on the cleaning wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com