Fluid-driven control valve

A fluid-driven, control valve technology, applied in the field of medical equipment, can solve the problems of affecting liquid mixing, increasing liquid flow resistance, and unsatisfactory mixing effect, so as to increase the flow speed and promote the effect of liquid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

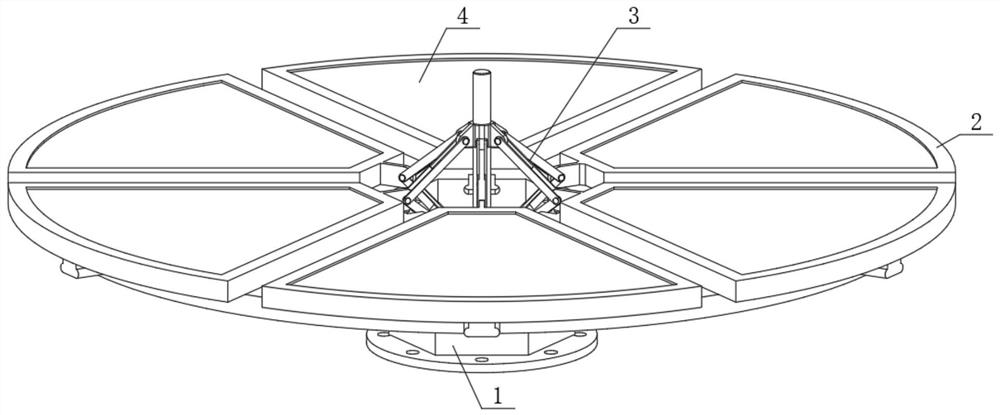

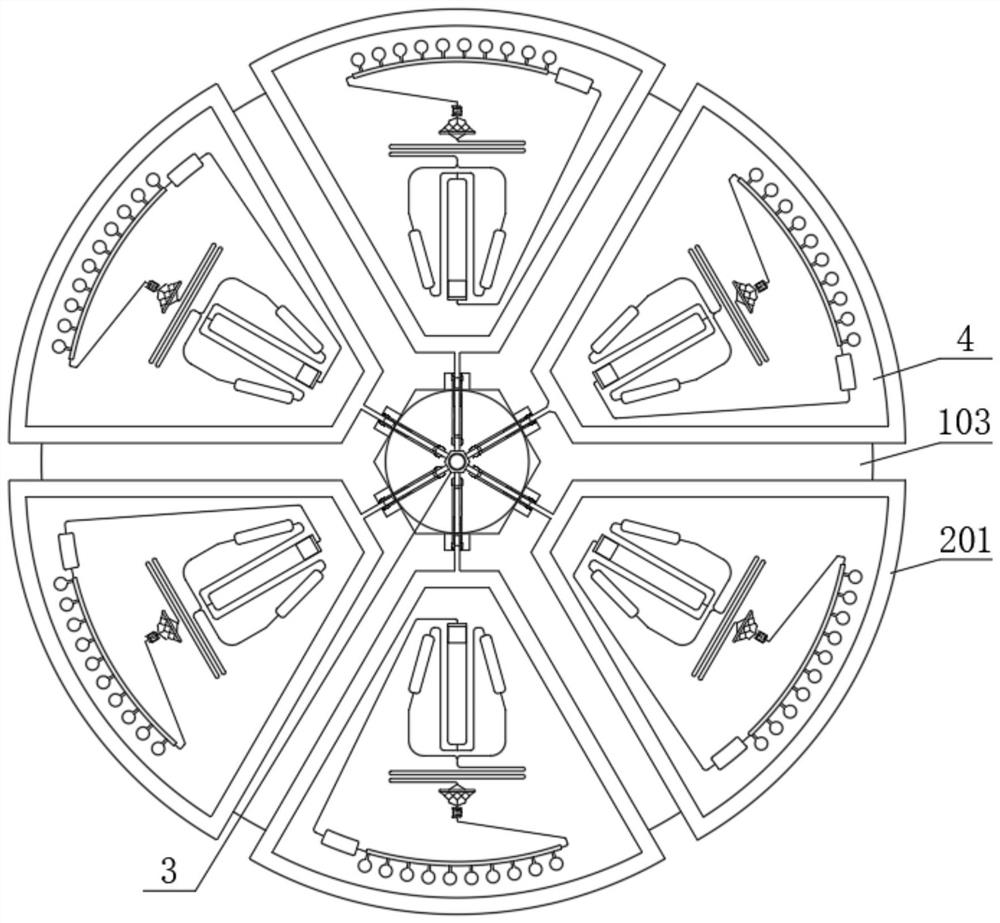

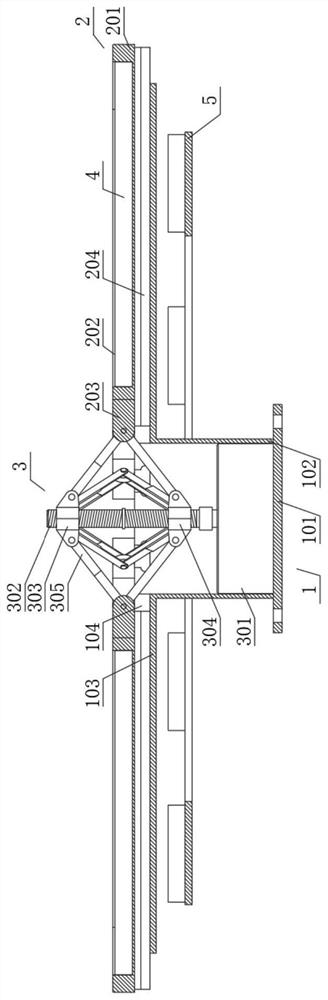

[0023]SeeFigure 1-2 , Fluid drive control valve, including support assembly 1, movable assembly 2, drive assembly 3, microfluid panel assembly 4, and magnetic assembly 5, such asimage 3 As shown, the support assembly 1 includes a support barrel 102 that is fixedly coupled with a support disk 103, and the top portion of the support disk 103 has a slide 104 in radially, the support disk 103 The bottom is fixedly connected to the drive disc 101, and the bottom portion of the drive disc 101 is fixed in its circumferential direction; the top portion of the support assembly 1 is connected to active assembly 2 along its circumferential activity, and the movable component 2 includes a movable board. 201, the bottom intermediate of the movable plate 201 is fixed to the slider 204, and the top of the movable plate 201 is opened, and the inner side of the movable plate 201 is fixedly connected to the connecting plate 203; the slider 204 slides Connected to the slot 104 of the top portion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com