Preparation device of windproof polyester fabric coating agent

A technology for polyester fabrics and preparation devices, applied in the field of polyester fabrics, can solve the problems of uneven feeding, easy clogging and sticking, inconvenient quantitative feeding, etc., and achieve the effects of avoiding feeding clogging, convenient quantitative feeding, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

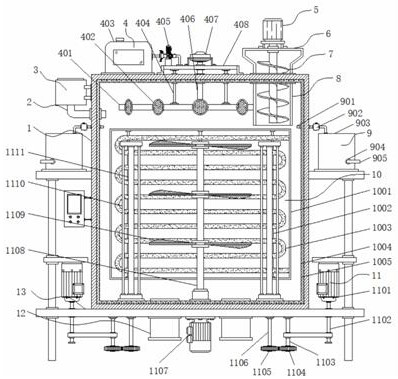

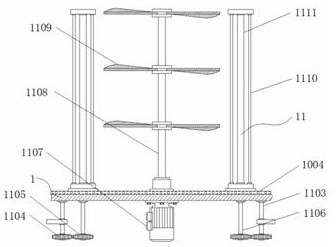

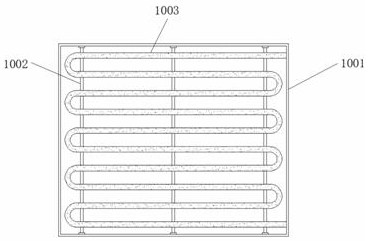

[0035] Example 1: See Figure 1-6 , a preparation device for a windproof polyester fabric coating agent, comprising a tank body 1 and a placement frame 13, the top of the placement frame 13 is fixedly connected with the tank body 1, and the both sides of the bottom end of the tank body 1 are respectively provided with discharge ports 12, and the tank body A cleaning mechanism 4 is provided in the middle of the top of the tank body 1, an exhaust mechanism 9 is provided on both sides of the tank body 1, a heating and heat preservation mechanism 10 is provided around the inner wall of the tank body 1, and a shearing and stirring mechanism is provided inside the tank body 1. 11. The top of the tank body 1 is provided with a feeding mechanism;

[0036] see Figure 1-6 A preparation device for a windproof polyester fabric coating agent also includes a feed mechanism, the feed mechanism includes a water tank 3, the water tank 3 is fixedly connected to the top of the tank body 1 side, ...

Embodiment 2

[0038] Embodiment 2: The cleaning mechanism 4 is composed of a water distribution pipe 401, a high-pressure nozzle 402, a liquid storage tank 403, a catheter 404, a high-pressure water pump 405, a rotating shaft 406, a reduction motor 407 and a hollow plate 408. The hollow plate 408 is fixedly connected to the tank body 1 In the middle of the top, the four corners of the bottom of the hollow plate 408 are movably connected with a catheter 404 through a rotary joint, the hollow plate 408 communicates with the catheter 404, and the bottom of the catheter 404 extends to the tank body 1 The interior of the water distribution pipe 401 is movably connected through the rotary joint. Ten groups of high-pressure nozzles 402 are arranged around the water distribution pipe 401. A liquid storage tank 403 is provided on one side of the hollow plate 408. The output end of the liquid storage tank 403 is provided with a high-pressure water pump. 405, the model of the high-pressure water pump 4...

Embodiment 3

[0041] Embodiment 3: Exhaust mechanism 9 is made up of exhaust pipe 901, solenoid valve 902, gas collection box 903, gas outlet 904 and connecting pipe 905, and gas collection box 903 is respectively arranged on the both sides of tank body 1, and gas collection box 903 An exhaust pipe 901 is arranged between the inside of the tank body 1, the input end of the exhaust pipe 901 extends to the inside of the tank body 1, and a solenoid valve 902 is arranged between the output end of the exhaust pipe 901 and the gas collection box 903, The model of the solenoid valve 902 can be 2W, the bottom of one end of the gas collection box 903 is provided with an air outlet 904, and the inside of the air outlet 904 is fixedly connected with a connecting pipe 905;

[0042] The connection pipe 905 is externally connected to the gas treatment device, and the horizontal position of the exhaust pipe 901 is lower than the bottom end of the feed pipe 8;

[0043] Specifically, such as figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com