Glue dipping device for brominated epoxy glass fiber cloth insulating plate production

A technology of glass fiber cloth and brominated epoxy, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven application of glue, difficult adjustment and conversion, and reduced production efficiency of products, so as to increase convenience Sexuality and work efficiency, uniform and comprehensive coverage, increase the effect of preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1, such as Figure 5 As shown, when the glue is replenished, the heating tube 12 and the servo motor B181 can be started through the console 15, and the servo motor B181 is used to drive the driving gear 182 and the driven gear 183 to mesh with each other to force the guide tube 184 to connect with the tapered glue outlet. 185 rotation, using the glue inlet 18 to receive the glue that needs to be replenished, the rotation guide of the guide tube 184 promotes the efficiency of glue delivery faster, and uses the tapered glue outlet 185 to discharge the glue under the action of centrifugal force, and Stirring is started by the rotation of the stirring rod 186, during which the glue solution is heated under the activation of the heating tube 12, so as to increase the preservation effect of the glue solution and the subsequent use accuracy.

Embodiment 2

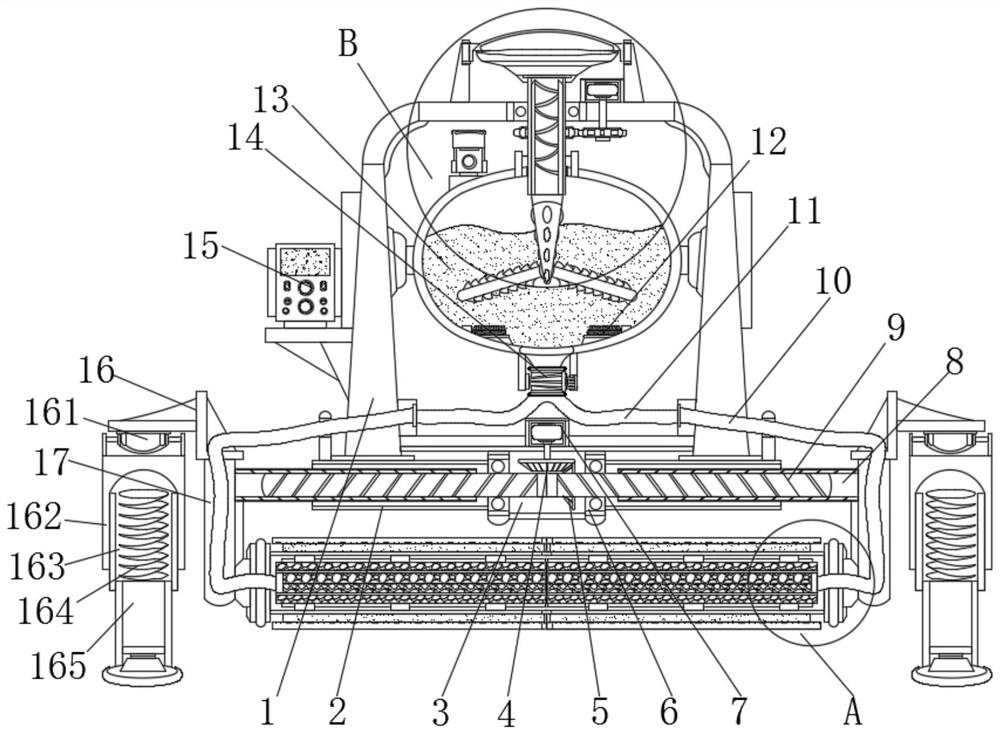

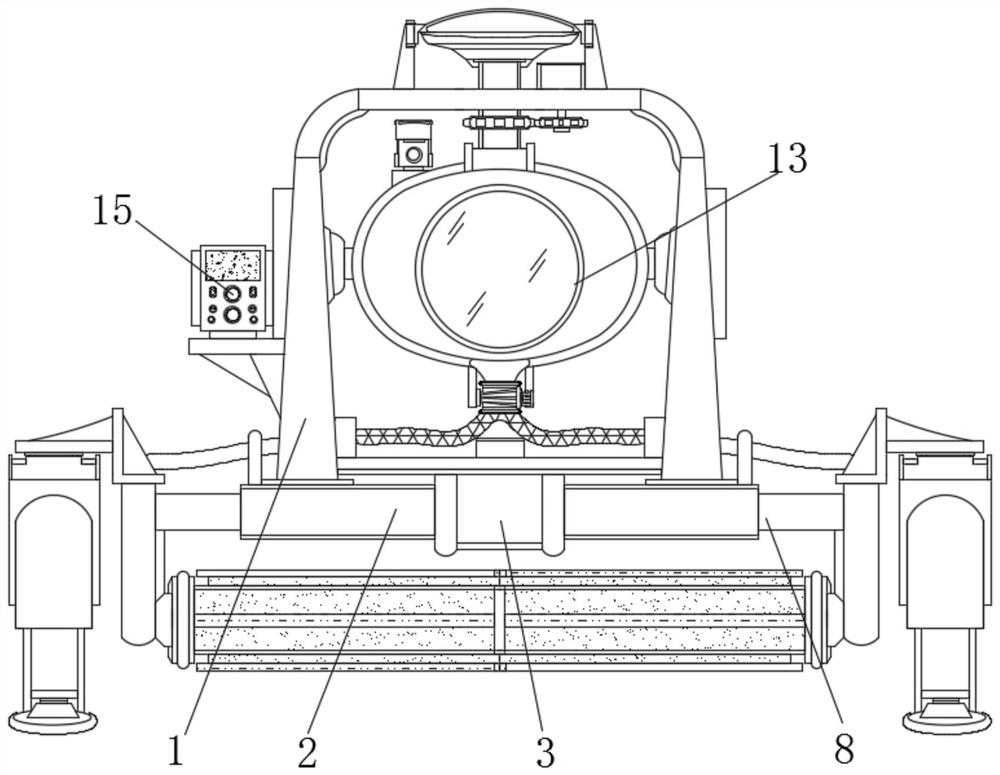

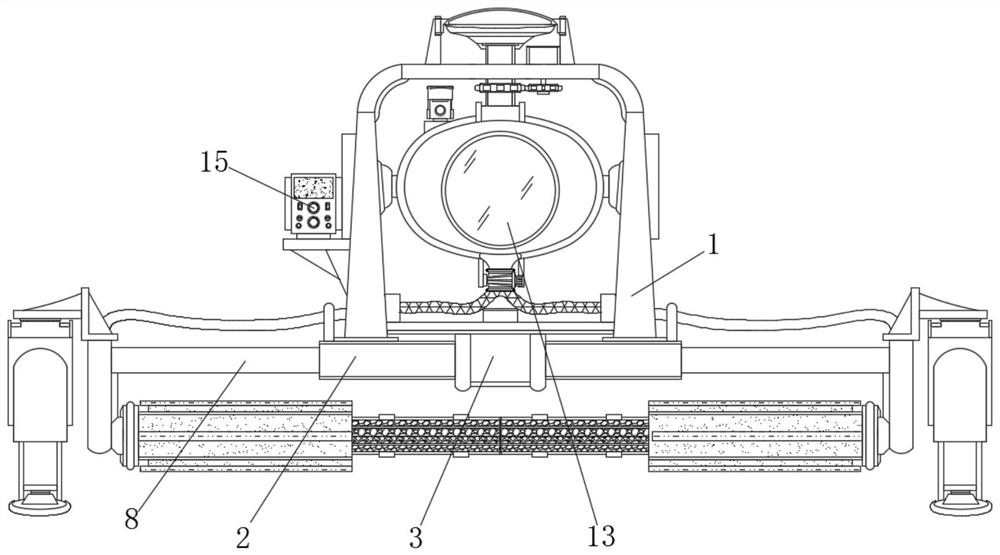

[0045] Example 2, such as figure 1 with Figure 7 As shown, when the glue needs to be applied, the whole device can be pressed, the inner sleeve 165 first contacts the object, and the inner sleeve 165 and the spring 164 retract and move under the elastic expansion and contraction of the outer sleeve 163, so that the outer rubber roller 171 contacts the insulation board that needs to be dipped in glue, and forms four sets of auxiliary positioning points under the elastic compression of the inner sleeve 165, and uses the sliding fit of the pulley block 161 and the chute 166 to guide the pulley block 161 to perform reciprocating dipping work. Not only is it easy to place the device directly when it is not in use, but it also ensures that it will not shake and slip during the dipping operation, increasing the functionality of the device and the stability of the dipping operation.

[0046] Working principle: when the device is in use, firstly start the servo motor A7 and the glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com