A vibrating coal separator

A technology of coal separator and movable frame, which is applied in the direction of solid separation, cleaning method using liquid, cleaning method and utensils, etc. It can solve the problems of large wear of the crusher, pollution of the working environment, damage to the arc system, etc., and achieve good cleaning effect, improve the effect of coal preparation, and avoid the effect of steel contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

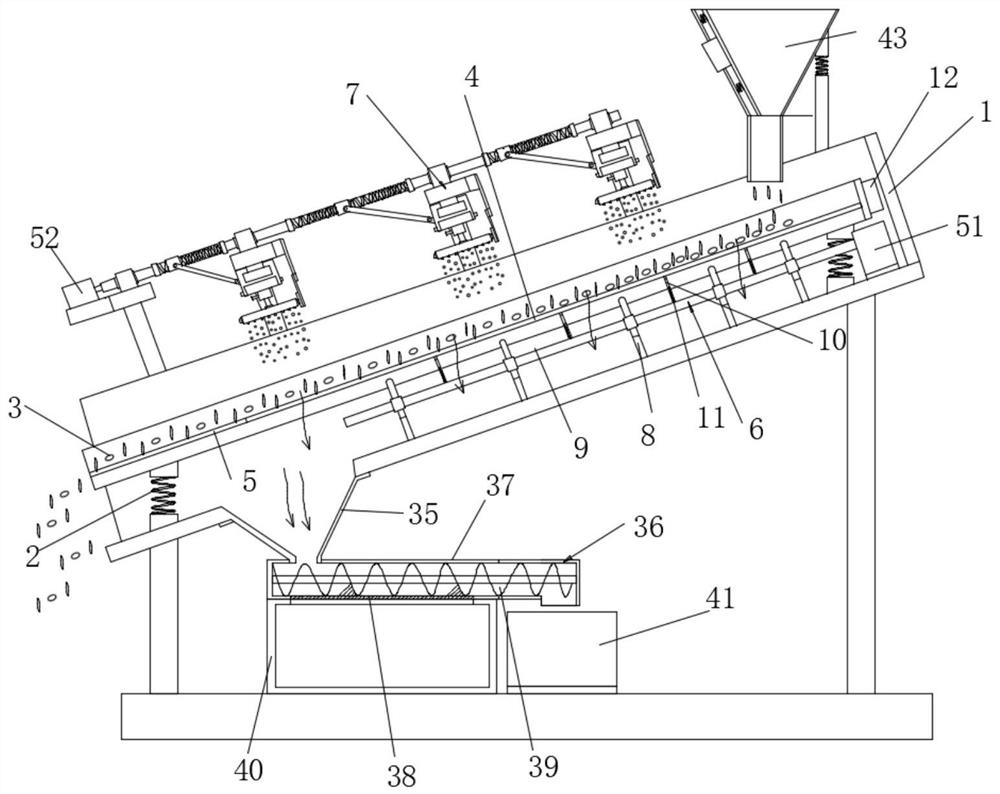

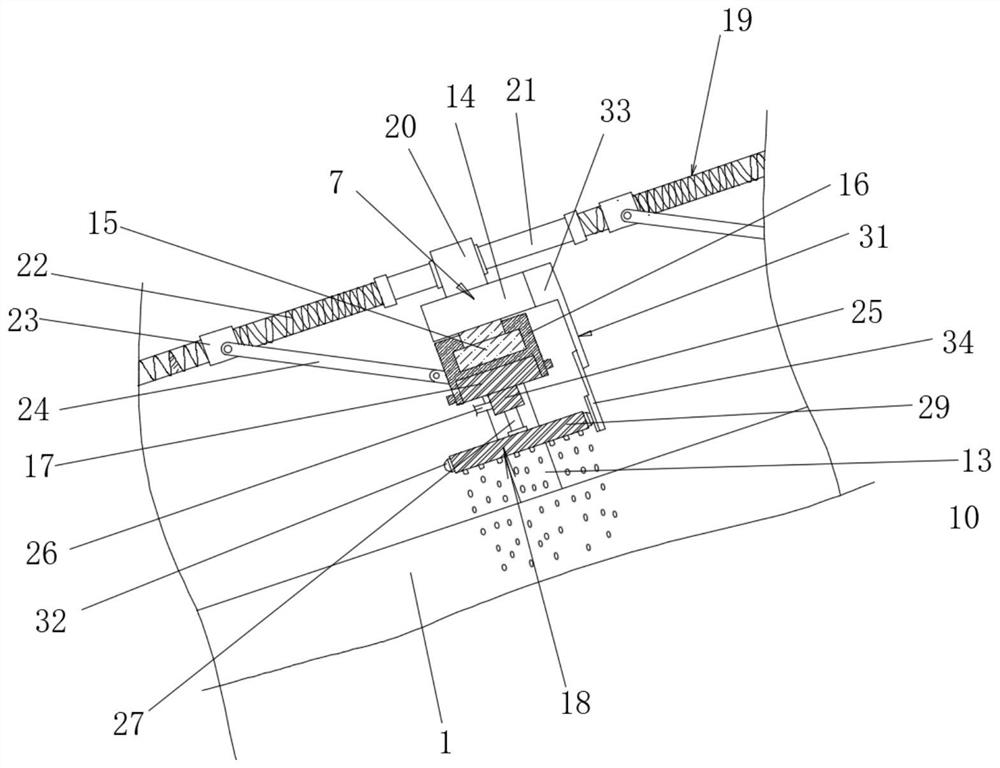

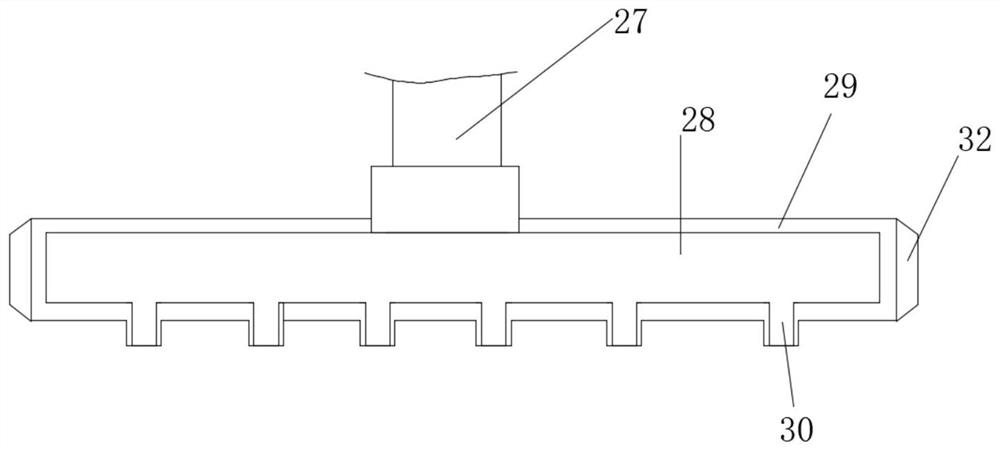

[0028] Embodiment: a kind of vibration coal separator, such as Figure 1-6 As shown, it includes a frame main body 1, on which a vibrating sieve bed 3 arranged obliquely is installed on the frame main body 1 via a spring shock absorber 2, on which a vibrating screen 4 is fixed, and on the vibrating sieve bed 3 The end of the vibrating screen 4 is provided with a material guide plate 5 that is docked with the vibrating screen 4. The vibrating screen bed 3 is provided with an anti-blocking and beating mechanism 6 for beating the bottom of the vibrating screen 4 at the bottom of the vibrating screen 4. The frame main body 1 is provided with a swing flushing mechanism 7 facing the vibrating screen 4. The anti-blocking and beating mechanism 6 includes a positioning frame 8 and is arranged on a rotating shaft 9 at the bottom of the vibrating screen 4. There are multiple arcs hinged on the rotating shaft 9. A beating rod 10 is formed, and a compression spring 11 is hinged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com