Extrusion rod for compacting inner surface of powder metallurgy part and manufacturing method of part

A technology of powder metallurgy and manufacturing method, which is applied in the field of powder metallurgy, can solve problems such as unsatisfactory cost and large mold loss, and achieve the effects of long mold life, performance improvement, and expanded application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 1 to Figure 12 Shown is the first preferred embodiment of the present invention.

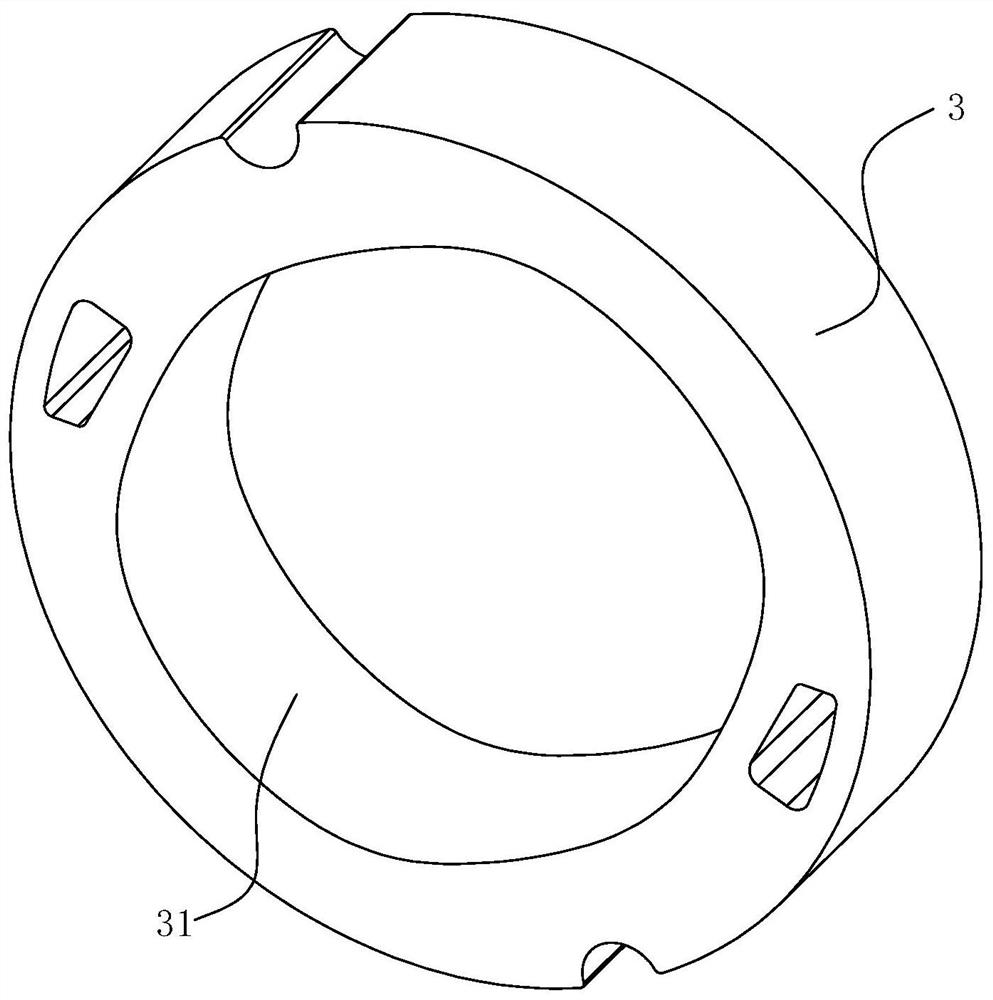

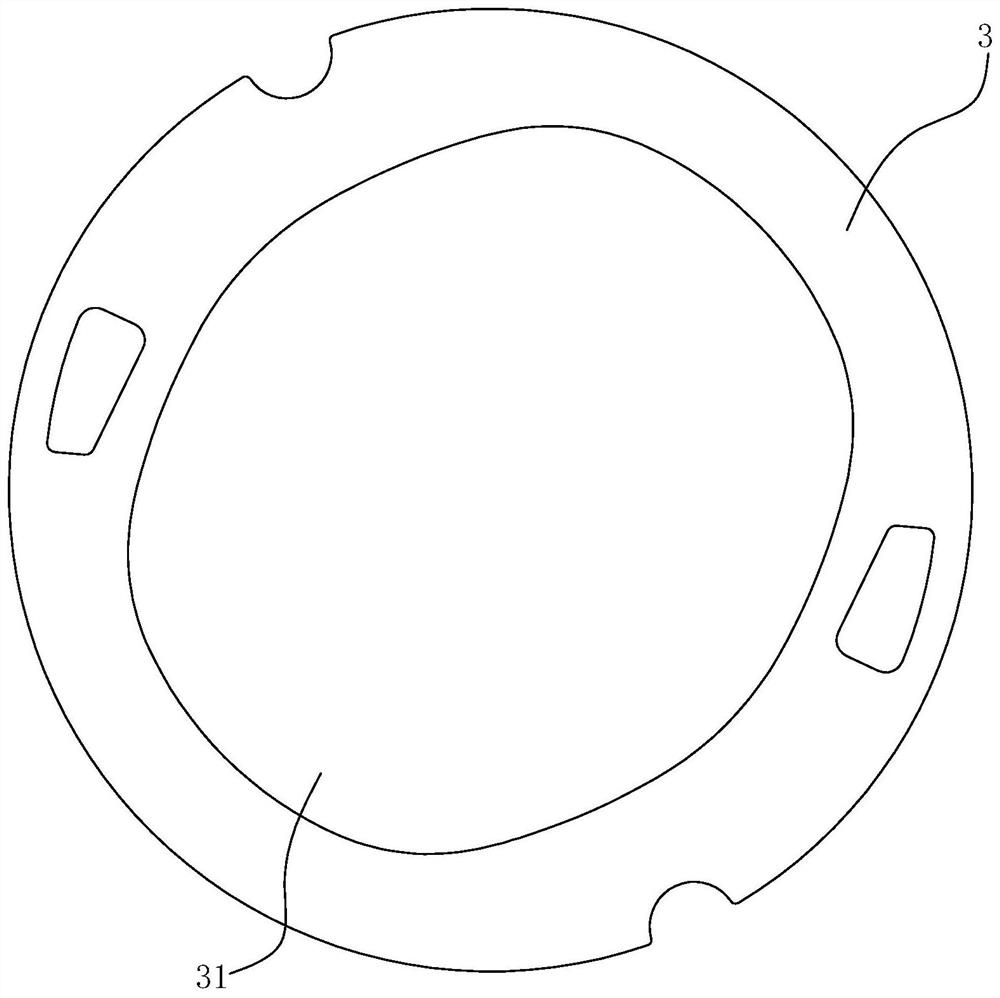

[0044] Such as image 3 As shown, the extrusion system of this embodiment includes a female mold 2 and an extrusion rod 1 used to compact the inner surface of powder metallurgy parts. The center of the female mold 2 is provided with a central hole 31 for the parts to be extruded In the opening 21 therein, a step 211 for placing parts 3 to be extruded is formed in the opening 21, such as Figure 7 As shown, the longitudinal section of the opening 21 of the female mold 2 is T-shaped. Such as figure 1 As shown, the center of the part 3 to be extruded has a central hole 31 .

[0045] Such as image 3 As shown, the extruded rod 1 of this embodiment includes a core rod 11 , an extruded part 12 , a support ring 13 , a guide part 14 and a nut 15 . The mandrel 11 is arranged vertically, and the longitudinal section of the mandrel 11 is substantially T-shaped. The mandrel 1 in...

Embodiment 2

[0055] The difference between this embodiment and the above-mentioned embodiment 1 is that: in step 5), the extrusion amounts of each gear are different, specifically, the total extrusion deformation design amount Δd is 5%, the extrusion amount of the first gear is 2.5%, and the extrusion amount of the second gear is 2.5%. 1.5% extrusion amount, 1% extrusion amount in the third gear, wherein the extrusion amount of the first gear is the extrusion amount after extrusion of the extrusion part 12 located at the bottom, and the extrusion amount of the second gear is the extrusion amount of the middle one. The extrusion amount of the extruded piece 12 after extrusion, and the extrusion amount of the third gear is the extrusion amount of the uppermost extrusion piece 12 after extrusion.

Embodiment 3

[0057] The difference between this embodiment and the above-mentioned embodiment 1 is that the composition design and parameter selection in the preparation method are different, as follows:

[0058] This embodiment uses the above-mentioned extruder to prepare the manufacturing method of powder metallurgy parts, which includes the following steps in turn:

[0059] 1) Material composition design: sintered steel is used, such as iron-chromium-molybdenum pre-alloyed powder and carbon-copper mixed powder. The composition is calculated according to mass percentage: atomized iron powder is 95.6%; carbon is 0.80% and copper powder is 3%. , and then add a lubricant with a content of 0.6%;

[0060] 2) Pressing: the mixed powder in step 1) is pressed on a press with a pressing pressure of 550 MPa and pressed to a density of 7.0 g / cm 3 green parts;

[0061] 3) Sintering: the green part of step 2) is sintered at a temperature of 1300° C., and the sintering time is 30 minutes;

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com