Internal profile production line

A production line and profile technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of reduced yield, too long or too short, and high requirements for the length of the heating channel, so as to improve the bonding strength and improve the bonding strength. The effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

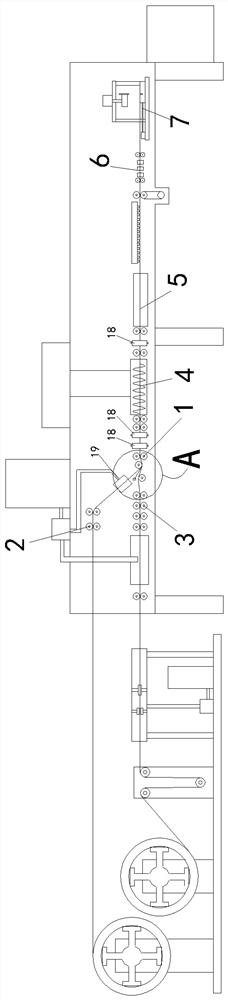

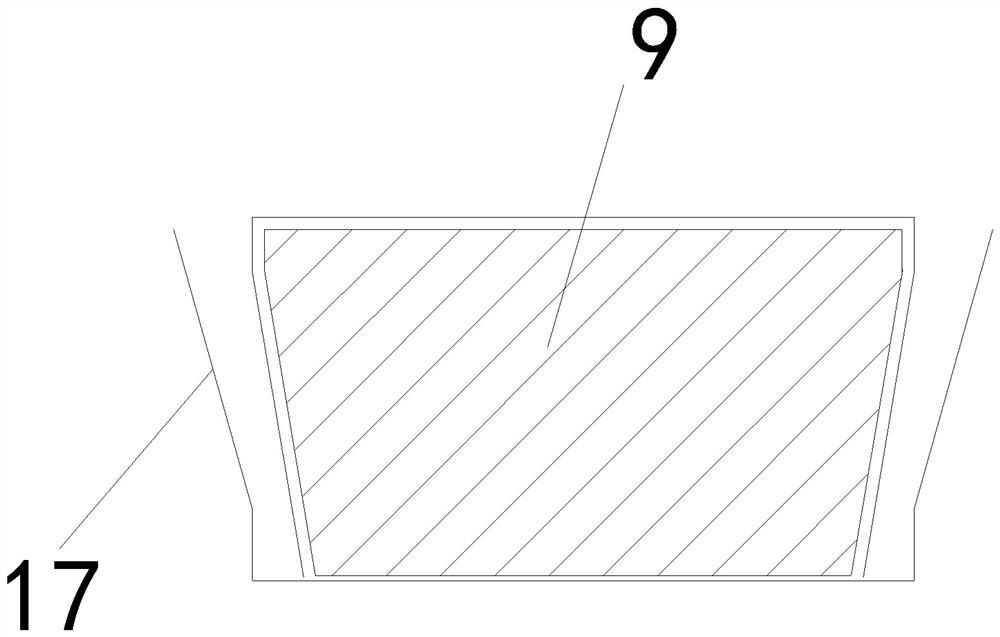

[0019] see Figure 1 to Figure 6 As shown, the spacer profile production line includes an extrusion roller 1 and its upstream heat insulation strip transfer roller 2 and metal sheet roller 3. The downstream of the extrusion roller 1 is sequentially provided with a heating channel 4, a cooling channel 5, a straightening device 6 and Slitting device 7, the upstream of extrusion roller 1 is also provided with the fixed frame 8 that is positioned at heat-insulation strip conveying roller 2 and sheet metal roll 3, is hinged on the fixed frame 8 with the extruding position that passes through extrusion roller 1 and passes through sequentially. Overheating channel 4, cooling channel 5 and straightening device 6 and lapped on the linear mandrel 9 on the workbench of cutting device 7, the end of mandrel 9 is positioned at the upstream of the slitting position on the workbench.

[0020] The mandrel 9 comprises an upstream section 10 positioned at the upstream of the cooling passage 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com