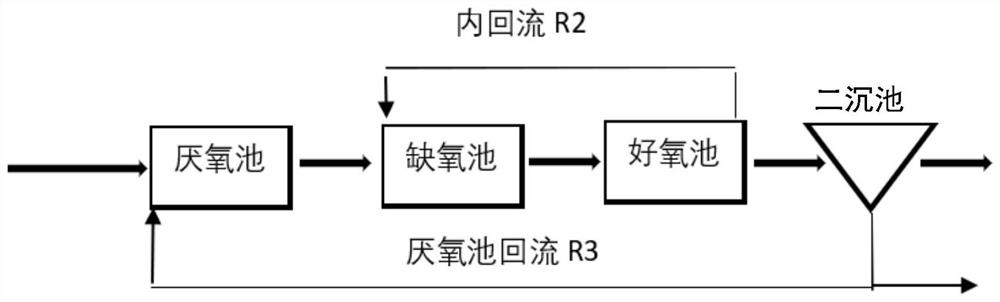

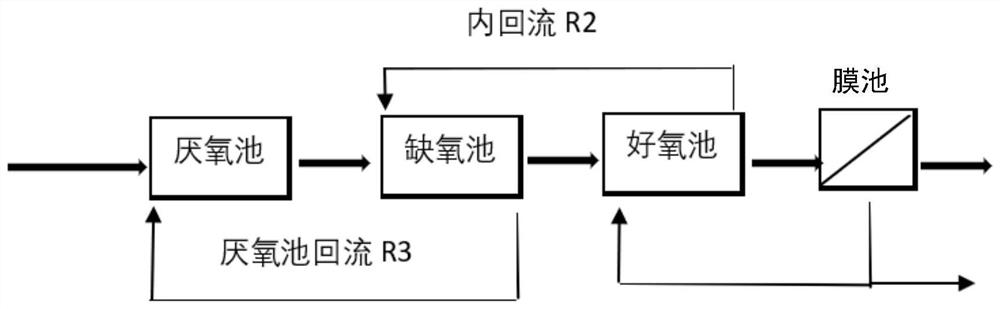

Optimization method of A2O biological nitrogen and phosphorus removal reflux ratio

A technology for biological denitrification and optimization methods, applied in chemical instruments and methods, reflux water treatment, sustainable biological treatment, etc., to achieve the effect of optimizing power consumption, power consumption and chemical consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A slaughter sewage plant treats 15000m of water 3 / d or 625m 3 / h, the process is anaerobic, anoxic and aerobic A 2 The O process is followed by a secondary settling tank and a high-efficiency inclined plate settling tank. In order to realize effective biological denitrification and phosphorus removal, according to the method of the present invention, the TN concentration of the influent supernatant of the anaerobic tank is sampled and measured to be 80 mg N / L, TP The concentration is 27mg P / L, PO 4 3- The concentration is 17mg / L, the total nitrogen concentration effluent discharge standard is 15mg N / L, and the total phosphorus concentration effluent discharge standard is 0.5mg P / L. According to the calculation formula of the inventive method, the denitrification total nitrogen removal rate is required to be 75%, and the internal reflux ratio R2 is calculated to be 340%, so the set internal reflux pump flow rate is 2125m 3 / h; the DO concentration of the internal re...

Embodiment 2

[0058] A municipal water plant treats 30,000m of water 3 / d or 1250m 3 / h, the process route is that the process is anaerobic, anoxic and aerobic A 2 O+MBR. On-site operation of the aerobic tank to the anoxic tank has a reflux ratio of 350%, and the anoxic tank to the anaerobic tank has a reflux ratio of 150%. At the same time, the DO concentration of the mud-water mixture near the internal reflux pump area is as high as 3.5mg / L. On-site It is necessary to add 50mg / L glucose to ensure that the total nitrogen stability reaches the standard. According to the method of the present invention, it is 30mg N / L, PO 4 3- The concentration is 1.0mg P / L, TP concentration is 2.0mg P / L; the effluent discharge standard for total nitrogen concentration is 15mg N / L, and the effluent discharge standard for total phosphorus concentration is 0.5mg P / L. According to the calculation formula of the inventive method, the denitrification total nitrogen removal rate is required to be 55%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com