Treatment method of sauce-flavor wine wastewater

A treatment method and technology for sauce-flavored wine, applied in the food industry wastewater treatment, natural water treatment, water treatment parameter control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

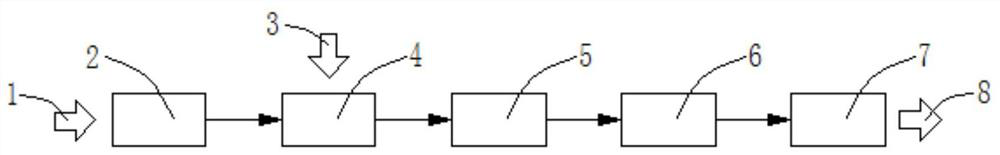

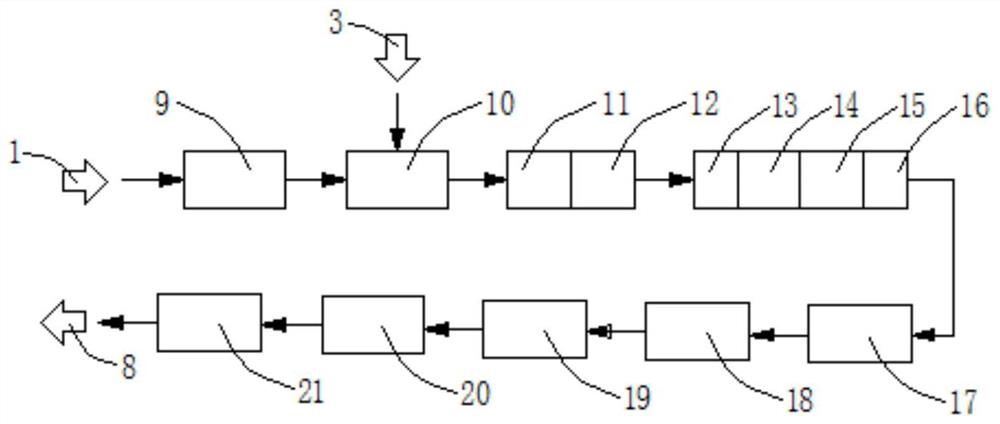

[0047] An embodiment of the present invention provides a Maotai-flavored wine wastewater treatment system, including a yellow water collection and storage system 2 , a pretreatment system 4 , a two-stage anaerobic system 5 , an AAO-AO biochemical system 6 and an advanced treatment system 7 .

[0048] Among them, the yellow water collection and storage system 2 is used to separately collect and store the high-concentration yellow water 1 produced during the production of Maotai-flavored wine.

[0049] The pretreatment system 4 is used for physical treatment of waste water. The collected high-concentration yellow water 1 is mixed with the waste water 3 produced in other production processes of Maotai-flavored wine in proportion to adjust the water quality and quantity to obtain reconciled waste water, and remove suspended solids and floating substances in the waste water. solid substances such as solids to ensure the smooth operation of the follow-up treatment system.

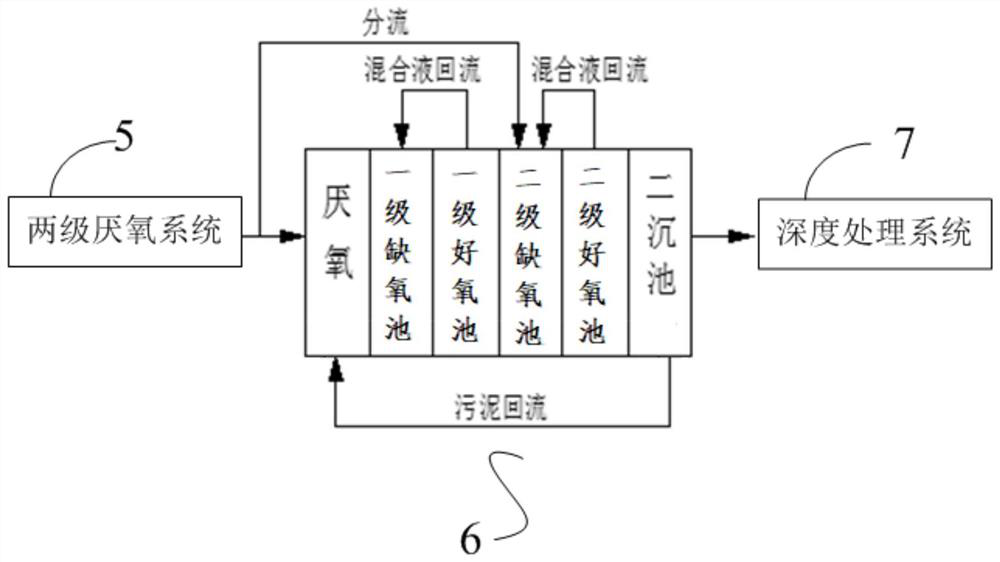

[0050]Th...

Embodiment 2

[0063] Embodiments of the present invention also provide a method for treating Maotai-flavored wine wastewater using the treatment system of Embodiment 1, comprising the following steps:

[0064] S1. Collect and store high-concentration yellow water: collect and store yellow water 1 during the production of Maotai-flavored wine.

[0065] S2. Wastewater pretreatment: the yellow water 1 stored in step S1 is mixed with the waste water 3 produced in other production steps of Maotai-flavored wine to obtain blended waste water.

[0066] S3. Anaerobic treatment: perform anaerobic treatment on the blended wastewater obtained in step S2, decompose the high-molecular organic matter in the blended waste water into small-molecular organic matter and biogas, and obtain primary treated wastewater.

[0067] S4. Anaerobic-anoxic-aerobic treatment: Anaerobic-anoxic-aerobic biochemical treatment is performed on the primary treatment wastewater obtained in step S3, and small molecular organic ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com