Petrochemical oil refining and coking equipment

A petrochemical and equipment technology, applied in coking ovens, petroleum industry, and furnaces to prevent/remove fouling, etc. It can solve the problems of waste gas treatment facilities, such as operational burden, damage, and easy blockage of the internal pipes of the exhaust gas absorption tower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

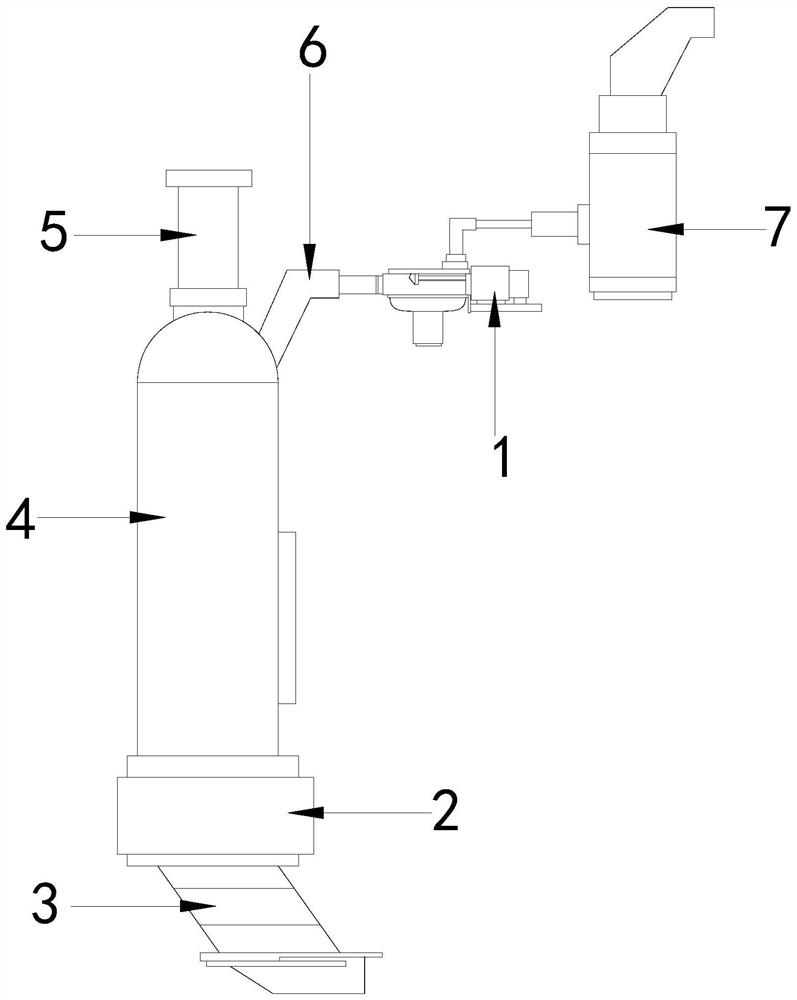

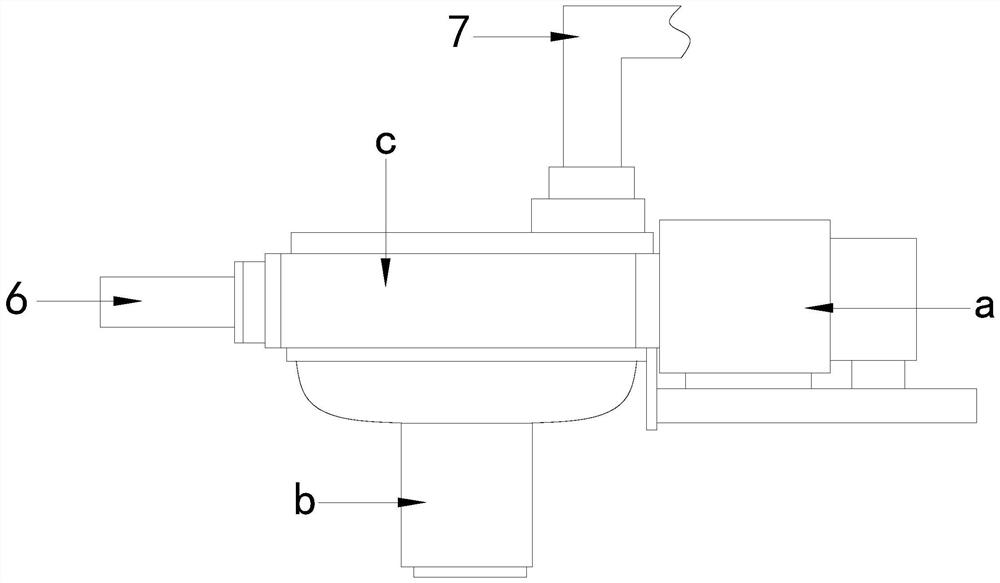

[0026] see Figure 1-Figure 3 , the present invention provides a technical solution for petrochemical refinery coking equipment: its structure includes: slag removal pipe body 1, bottom cover machine 2, connecting tank frame 3, coking furnace 4, top cover machine 5, connecting pipe 6, tail gas absorption tower 7. The connecting tank frame 3 is installed under the bottom cover machine 2 and locked with the bottom cover machine 2. A coking furnace 4 is arranged above the bottom cover machine 2, and the coking furnace 4 is fastened to the bottom cover machine 2. A top cover machine 5 is arranged above the coking furnace 4, and the top cover machine 5 is locked with the coking furnace 4. A connecting pipe 6 is provided on the right side of the coking furnace 4, and a slag removal pipe is provided on the outside of the connecting pipe 6. Body 1, the slag removal pipe body 1 is fastened to the connecting pipe 6, the tail gas absorption tower 7 is arranged on the outside of the slag ...

no. 2 example

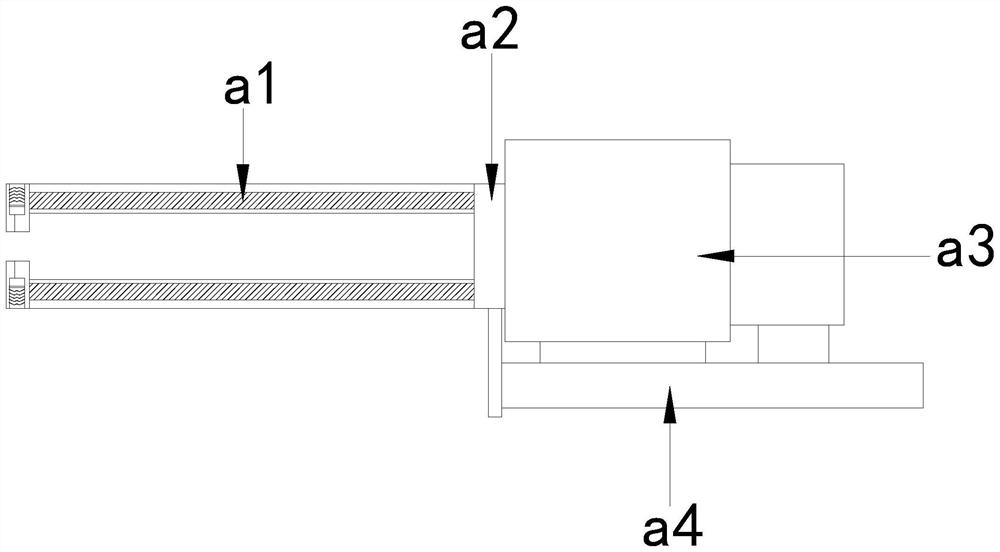

[0030] see Figure 4-Figure 6 , the present invention provides a technical solution for petrochemical refinery coke equipment: its structure includes: the contact pipe device a1 includes a friction block device a11, an installation rod a12, and an assembly groove block a13, and the friction block device a11 is installed on the assembly groove block The inner side of the a13 is in clearance fit with the assembly groove block a13, and the side of the assembly groove block a13 is provided with an installation rod a12, and the installation rod a12 is fastened with the assembly groove block a13.

[0031] The friction block device a11 includes a support block a111, a friction panel a112, a spring sleeve a113, and an airbag buffer ball a114. The friction panel a112 is installed on the outside of the support block a111 and fastened with the support block a111. There is an airbag buffer ball a114, and a spring sleeve a113 is sleeved on the outside of the airbag buffer ball a114, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com