Sliding door structure, grinding device comprising sliding door structure and steel rail grinding wagon

A technology for rail grinding car and sliding door, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of upper space limitation, limited opening and closing angle of the car door, inconvenience, etc., and achieve the effect of convenient and fast maintenance work and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

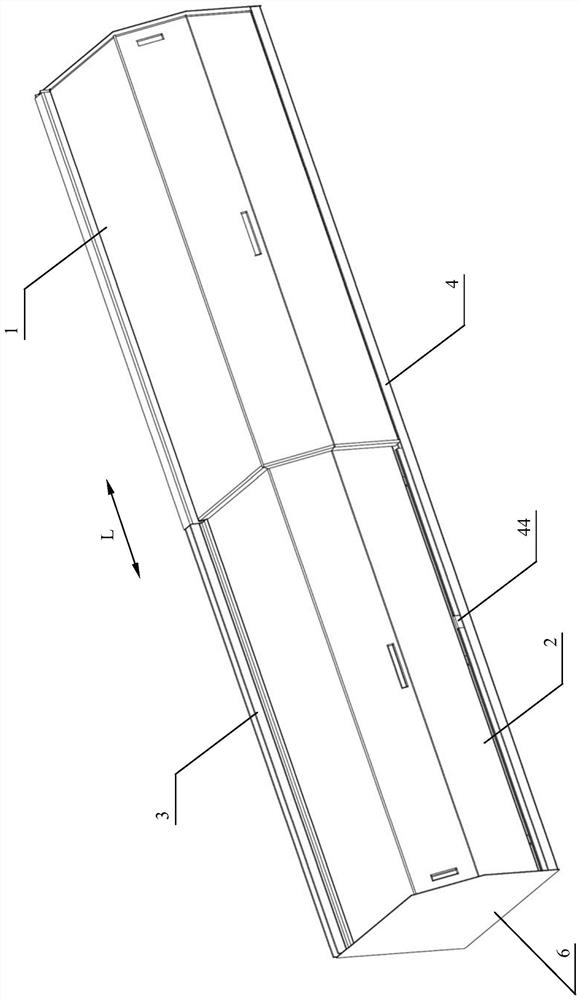

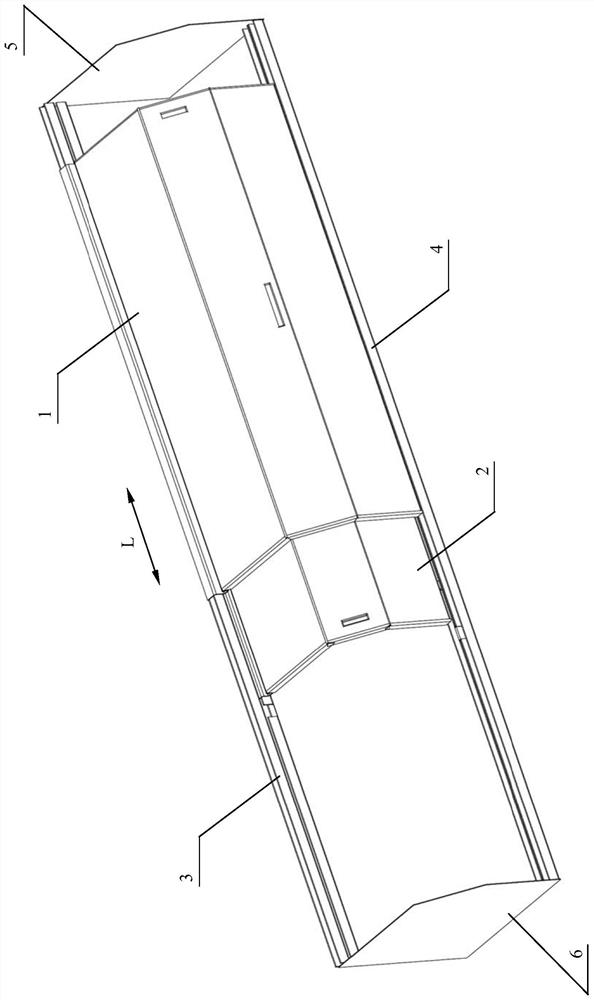

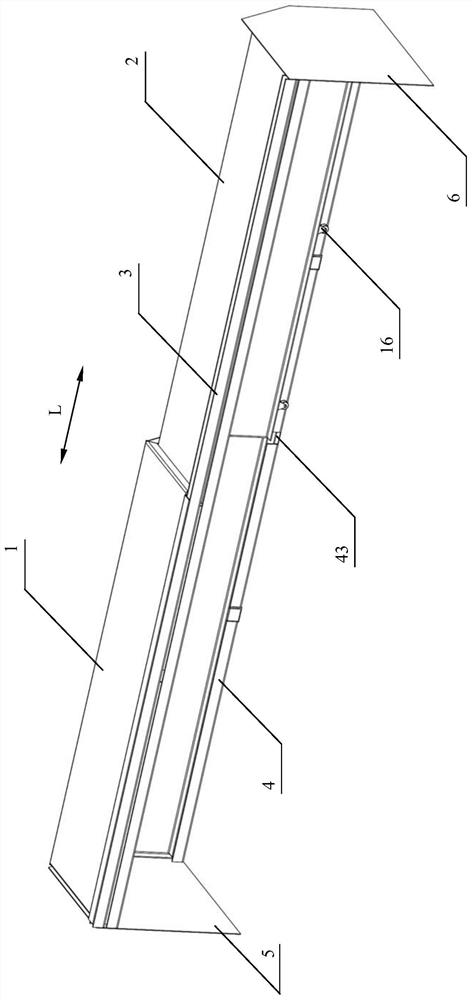

[0054] as attached figure 1 , 2 As shown in and 3, an embodiment of a sliding door structure is installed on the side of the grinding device 100, and the sliding door structure 10 specifically includes:

[0055] The first limiting part 3 and the second limiting part 4 extend along the working direction of the rail grinding vehicle 200 (as shown by L in the drawing) and are arranged parallel to each other. The first limiting part 3 is arranged on the top of the grinding device 100 , the second limiting portion 4 is disposed on the side of the grinding device 100;

[0056] The first baffle plate 5 and the second baffle plate 6 respectively installed on the front and rear ends of the first limiter 3 and the second limiter 4 along the working direction of the rail grinding vehicle 200;

[0057] The first sliding door 1 and the second sliding door 2 are installed between the first baffle plate 5 and the second baffle plate 6 along the front and rear direction of the rail grinding...

Embodiment 2

[0068] as attached Figure 13 As shown, a specific embodiment of the grinding device 100 including the sliding door structure 10 described in Embodiment 1, the sliding door structure 10 is installed on the side of the grinding device 100 . The grinding device 100 also includes a top cover 20 , a dust collection channel 30 , an end baffle 40 and a fire curtain 50 . The dust collection channel 30 is arranged on the upper part of the top cover plate 20 , and the dust generated during the grinding process enters into the dust collection device through the dust collection channel 30 . The end baffles 40 are arranged at the bottom of the front and rear ends of the top cover 20 along the working direction of the rail grinding vehicle 200 , and the sliding door structure 10 and the bottom of the end baffles 40 are connected with fire curtains 50 .

Embodiment 3

[0070] as attached Figure 14 Shown is a specific embodiment of a rail grinding vehicle 200 including the grinding device 100 described in Embodiment 2. The grinding device 100 is integrally installed under the car body 300 of the rail grinding vehicle 200 .

[0071] By implementing the sliding door structure described in the specific embodiments of the present invention, including the technical solution of the grinding device of the structure and the rail grinding car, the following technical effects can be produced:

[0072] (1) The sliding door structure described in the specific embodiment of the present invention includes the grinding device of the structure and the rail grinding car, the sliding door adopts a double-sided sliding door structure, and the sliding door structure is adjusted according to the actual situation by moving the left and right sliding doors during use The door opening width and position are more convenient and flexible, which not only avoids the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com