Carrier line short-circuit protection control method and circuit for carrier control welding machine

A control circuit and short-circuit protection technology, which is applied in emergency protection circuit devices, overvoltage-responsive protection, emergency protection devices for automatic disconnection, etc., can solve the short circuit between carrier wire and welding cable, carrier wire and welding base material Problems such as short circuit and frequent overcurrent impact of welding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

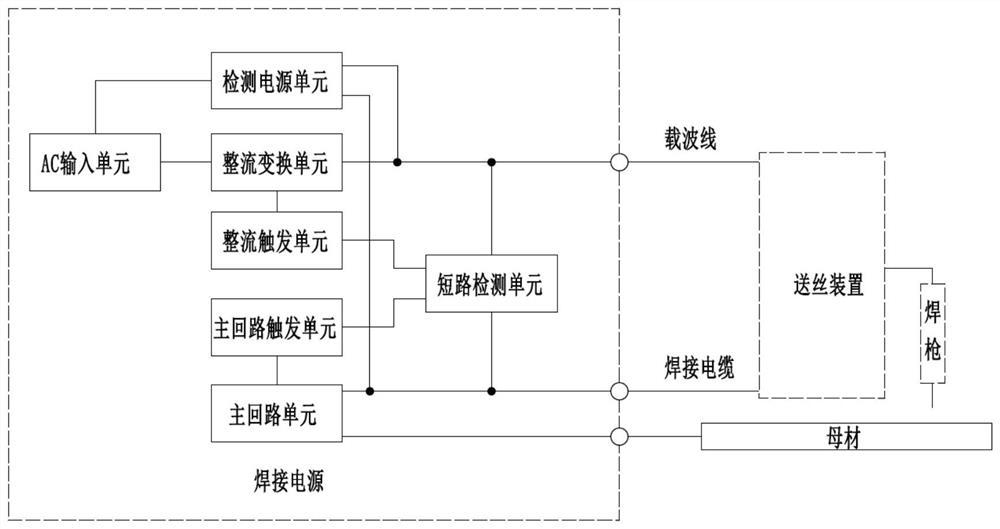

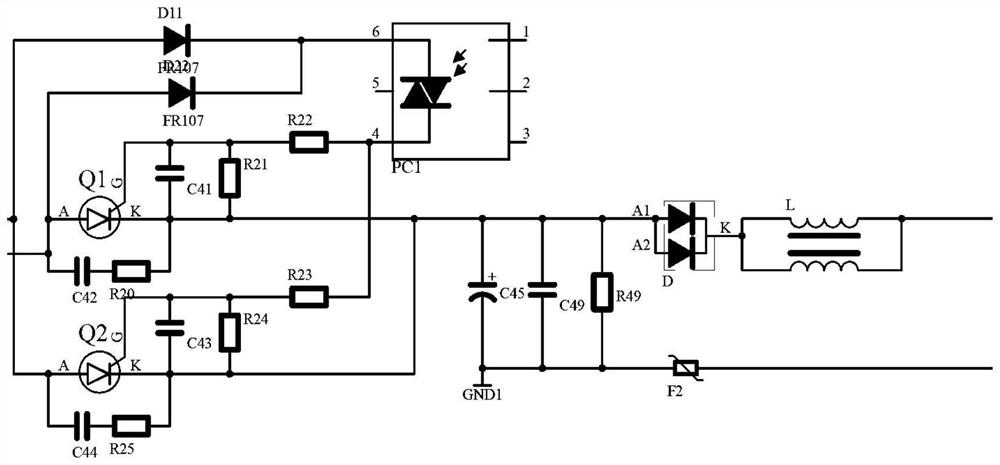

[0042] A kind of carrier line short circuit protection control circuit for carrier wave control welding machine of the present application, such as figure 1 As shown, it includes AC input unit, rectification conversion unit, detection power supply unit, rectification trigger unit, short circuit detection unit, main circuit unit, and main circuit trigger unit. The trigger unit and the rectification trigger unit are connected; the rectification conversion unit is respectively connected with the AC input unit and the rectification trigger unit, and leads out to the carrier terminal; the main circuit unit is connected with the AC input unit, the main circuit trigger unit, and leads out to the welding cable end and the busbar end , the main circuit unit includes AC input; the detection power unit is connected to the welding cable end, the bus bar end, and the AC input unit; the wire feeding device is respectively connected to the welding cable end, the bus bar end, and the welding t...

specific Embodiment 2

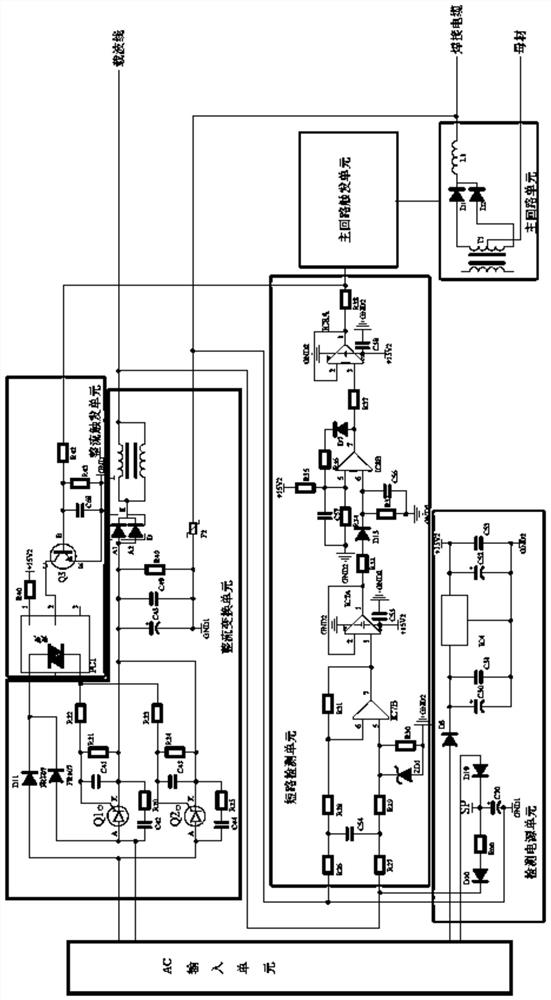

[0055] A kind of carrier line short circuit protection control circuit for carrier wave control welding machine of the present application, such as figure 2 As shown, the AC input unit provides AC power to the rectification conversion unit and the detection power supply unit, and the rectification conversion unit performs first rectification and filtering on the AC power, and then provides DC power to the carrier terminal and the welding cable terminal. Similarly, the detection power supply unit provides DC power to the carrier wire end and the welding cable end after performing second rectification and filtering on the AC power.

[0056] The carrier line end and the welding cable end serve as the two input ends of the short-circuit detection unit at the same time. The short-circuit detection unit detects the first voltage between the carrier line end and the welding cable end, compares it with the first preset value, and outputs according to the comparison result The control...

specific Embodiment 3

[0097] A carrier line short-circuit protection control method for a carrier-controlled welding machine of the present application, such as Figure 7 As shown, it includes detecting the first voltage at both ends of the carrier line and the welding cable. When the first voltage is less than the first set threshold, the carrier line power supply and the main circuit are turned off, and the welding machine is stopped; the carrier line circuit applies the detection power. If The carrier line is in a short-circuit state. When the detection voltage is less than the second set threshold, keep the carrier line power off; Circuit blocked.

[0098] In a specific embodiment of the present application, the first set threshold and the second set threshold are equal.

[0099] Such as Figure 7 shown, including the following steps:

[0100] S1, the carrier line power supply provides detection voltage;

[0101] S2. Detecting the first voltage at both ends of the carrier line and the weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com