Method for manufacturing metallic pipe, and method for washing metallic pipe

A manufacturing method and technology of metal tubes, applied in metal extrusion cleaning equipment, cleaning methods using liquids, manufacturing tools, etc., can solve problems such as difficult to remove coatings, and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] Hereinafter, the present invention will be described in more detail through examples. However, the present invention is not limited to the following examples.

[0157] [Example]

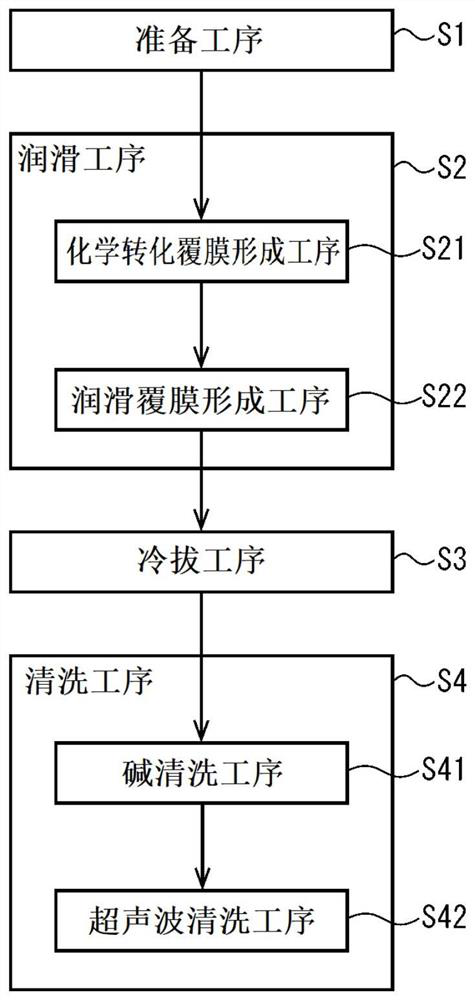

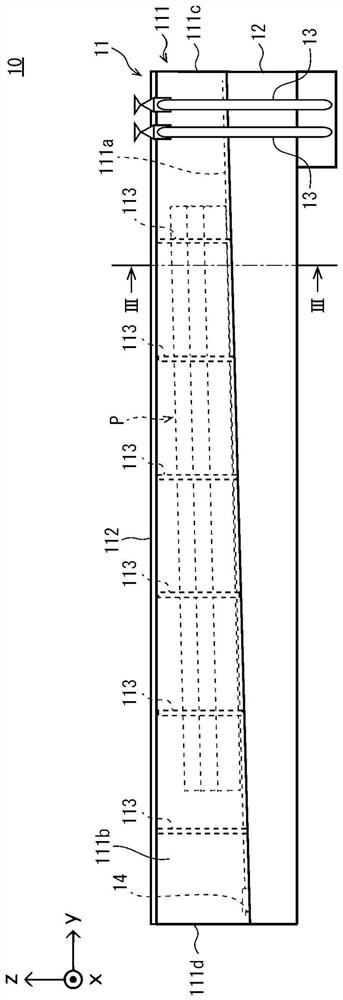

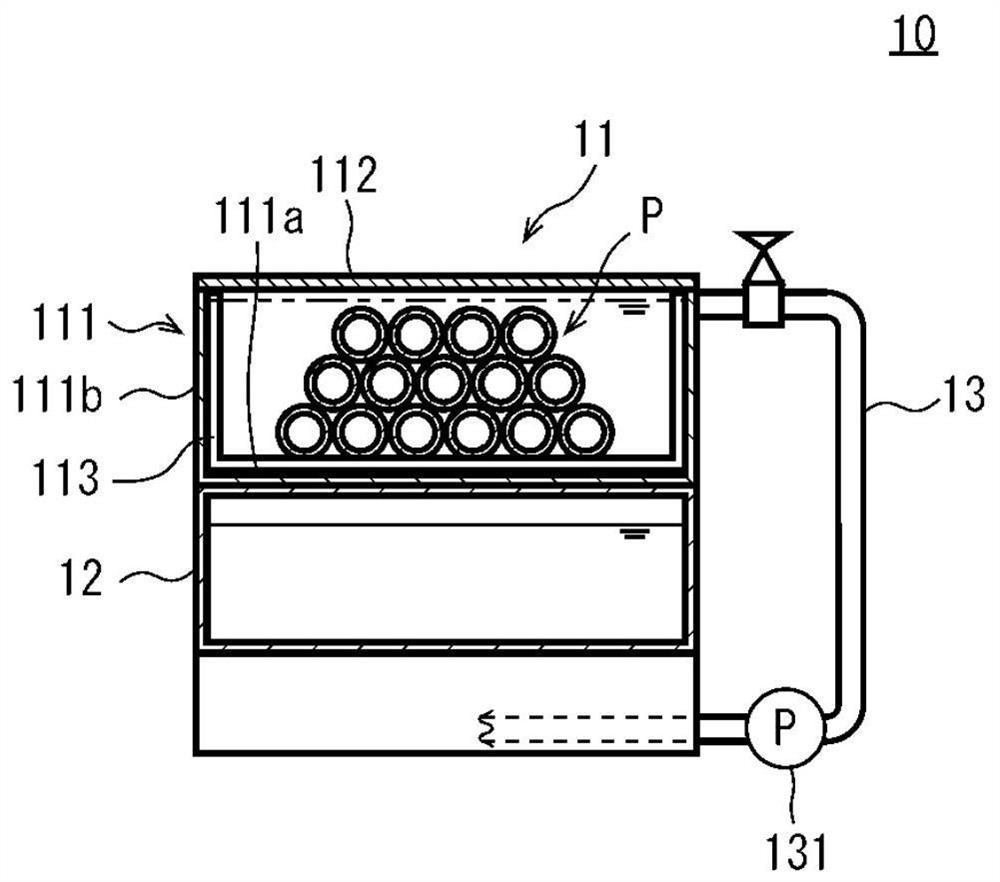

[0158] In order to confirm the cleaning effect of the metal pipe of the present invention, use figure 2 Alkaline cleaning device 10 shown and Figure 4 In the ultrasonic cleaning device 20 shown, a cleaning test of the cold-drawn metal pipe P was performed. That is, in the alkaline cleaning device 10 , after the alkaline cleaning process is performed with an alkaline degreasing solution that has not been heated at a high temperature, in the ultrasonic cleaning device 20 , an ultrasonic cleaning process is performed with a cleaning solution to which ultrasonic waves and microbubbles are applied. In this embodiment, the temperature of the alkali degreasing liquid used in the alkali cleaning step is a temperature determined according to the surrounding temperature of the alkali cleaning devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com