Retarding type mopping robot

A mopping robot and cleaning wheel technology, applied in robot cleaning machines, machine parts, carpet cleaning, etc., can solve problems such as poor cleaning effect, deterioration of cleaning time, and environmental pollution by tractor robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with specific embodiments.

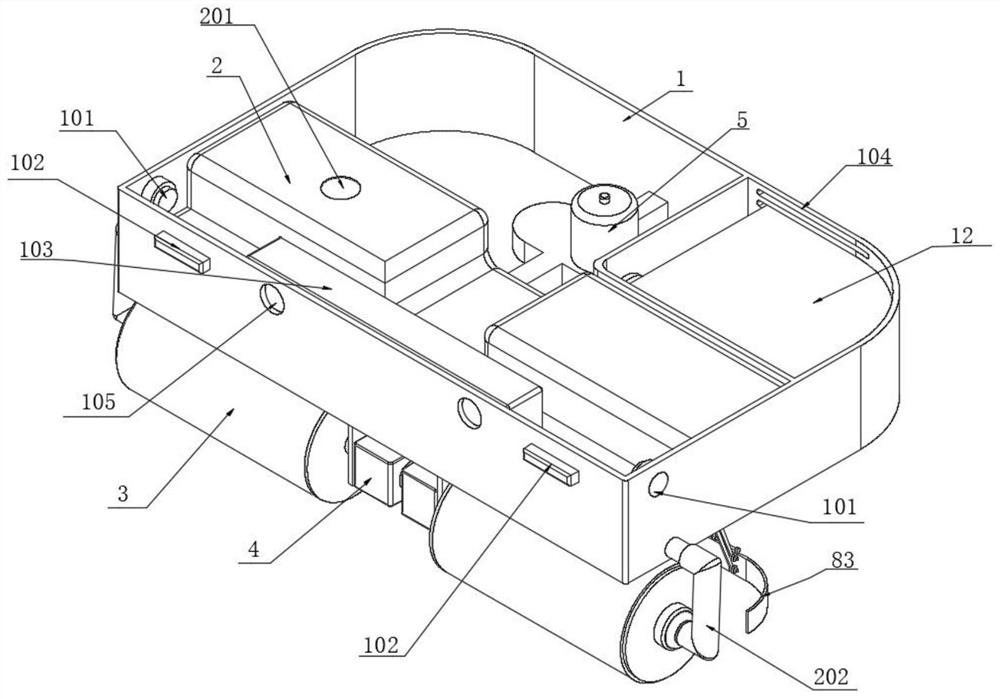

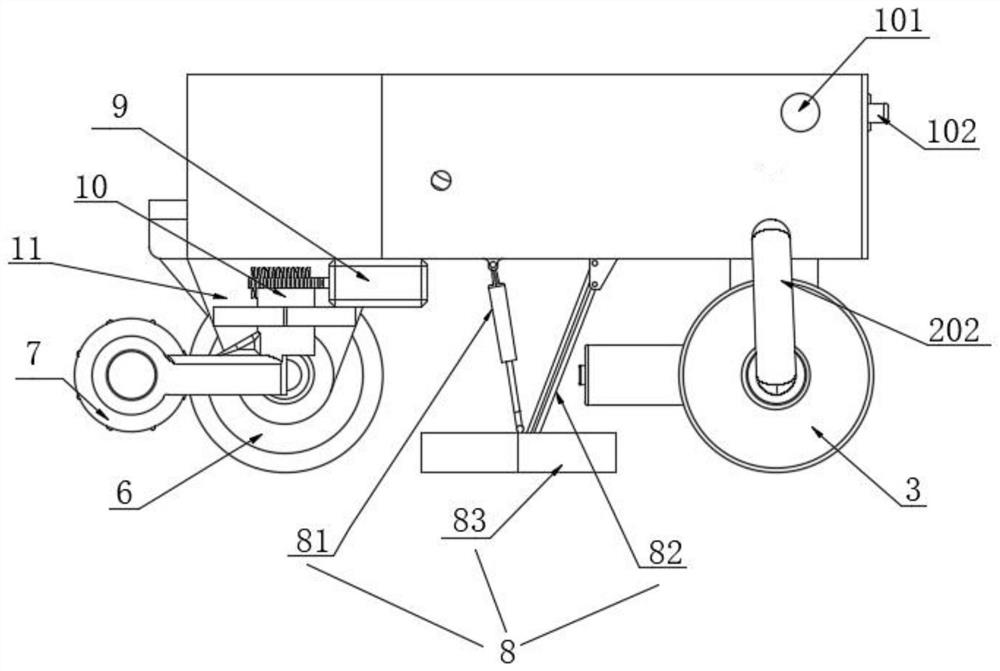

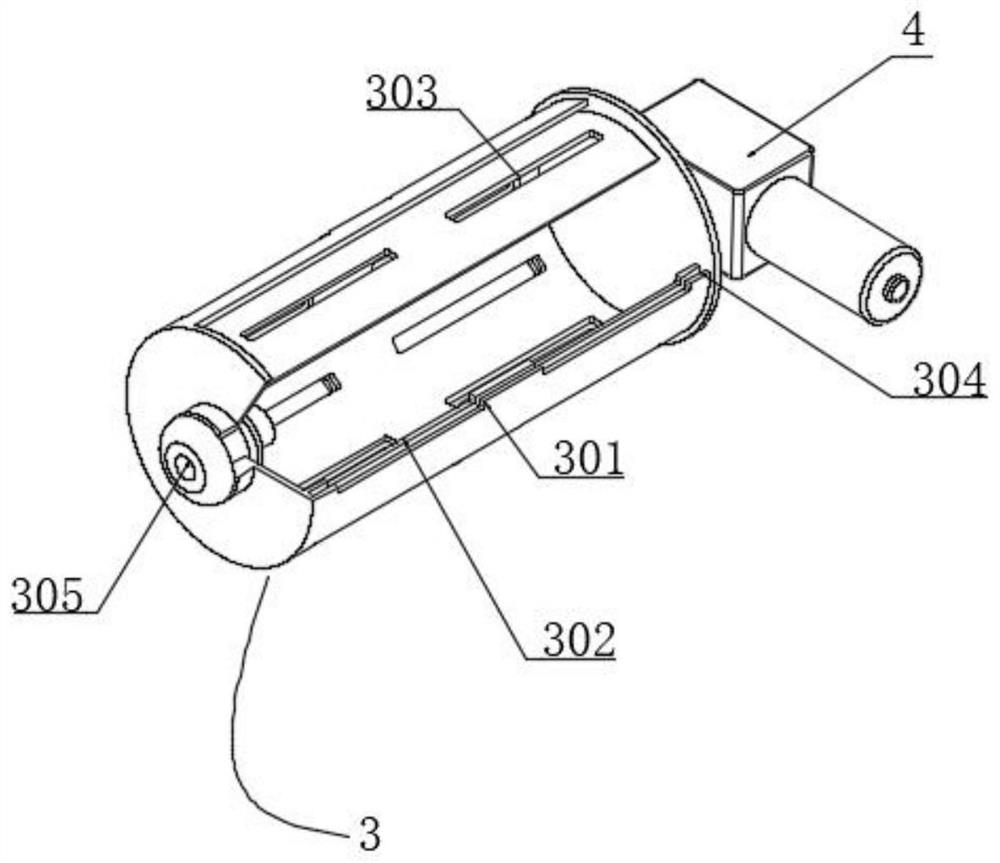

[0035] refer to Figure 1-9 , a drag mopping robot, including a housing 1 and a clean water tank 2 arranged inside the housing 1, two driving motors 4 are arranged side by side in the middle of one side of the bottom surface of the housing 1, and the driving motors 4 communicate with each other through a bracket. The housing 1 is fixedly connected, and the output ends of the two driving motors 4 are fixedly connected to one end of the front driving cleaning wheel 3. The interior of the front driving cleaning wheel 3 is a cavity structure, and the other end of the front driving cleaning wheel 3 is connected to the clean water tank through the clean water conduit 202. 2 are connected, the top of the fresh water tank 2 is provided with a water injection port 201, the housing of the front drive cleaning wheel 3 is provided with a water passing structure 303, and the bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com