Energy-saving and environment-friendly reaction device for resin production

An energy-saving and environmentally friendly reaction device technology, applied in the field of resin, can solve the problems of heat control, increase of resin reaction time, increase of resin energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

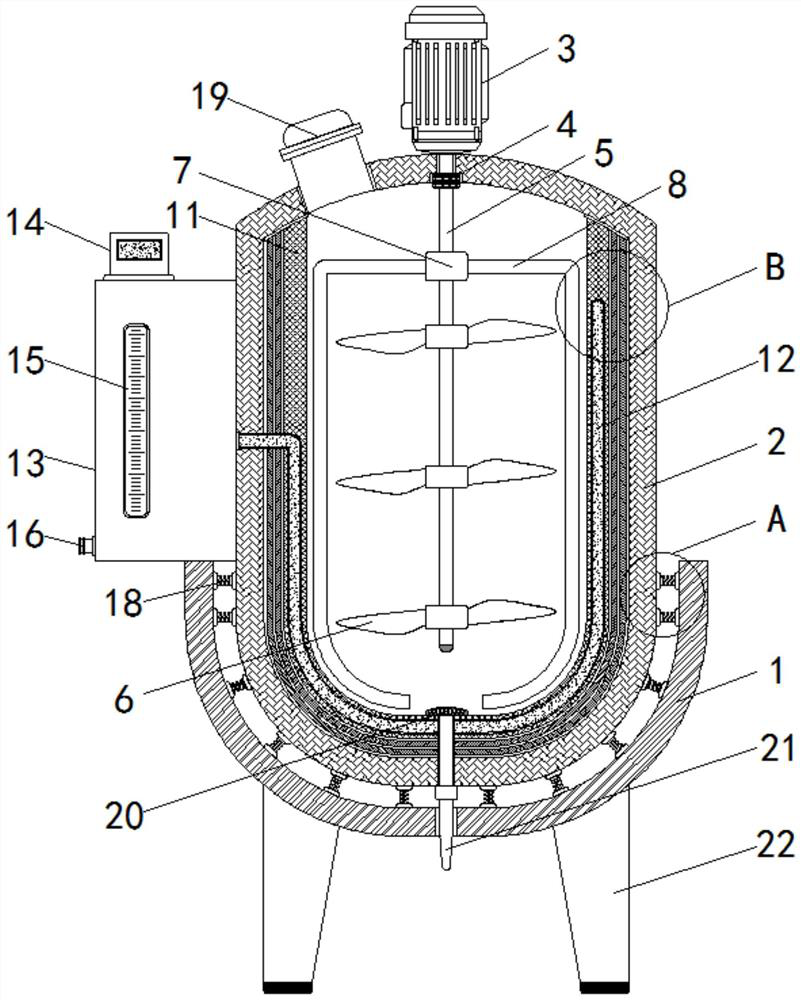

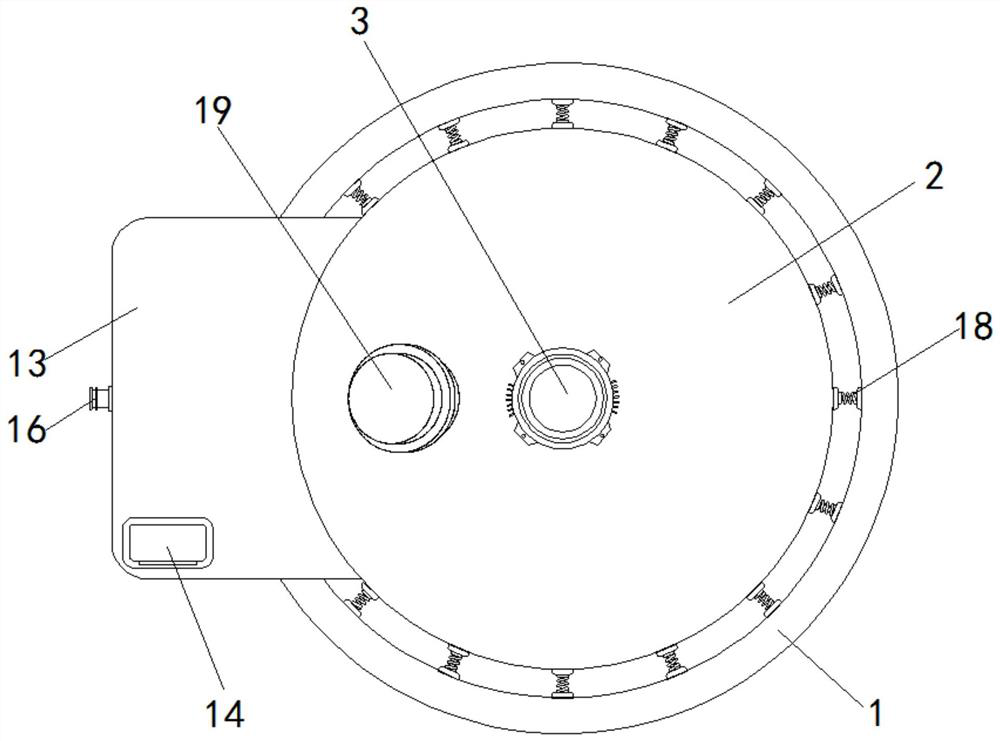

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] as attached figure 1 to attach Figure 4 Shown:

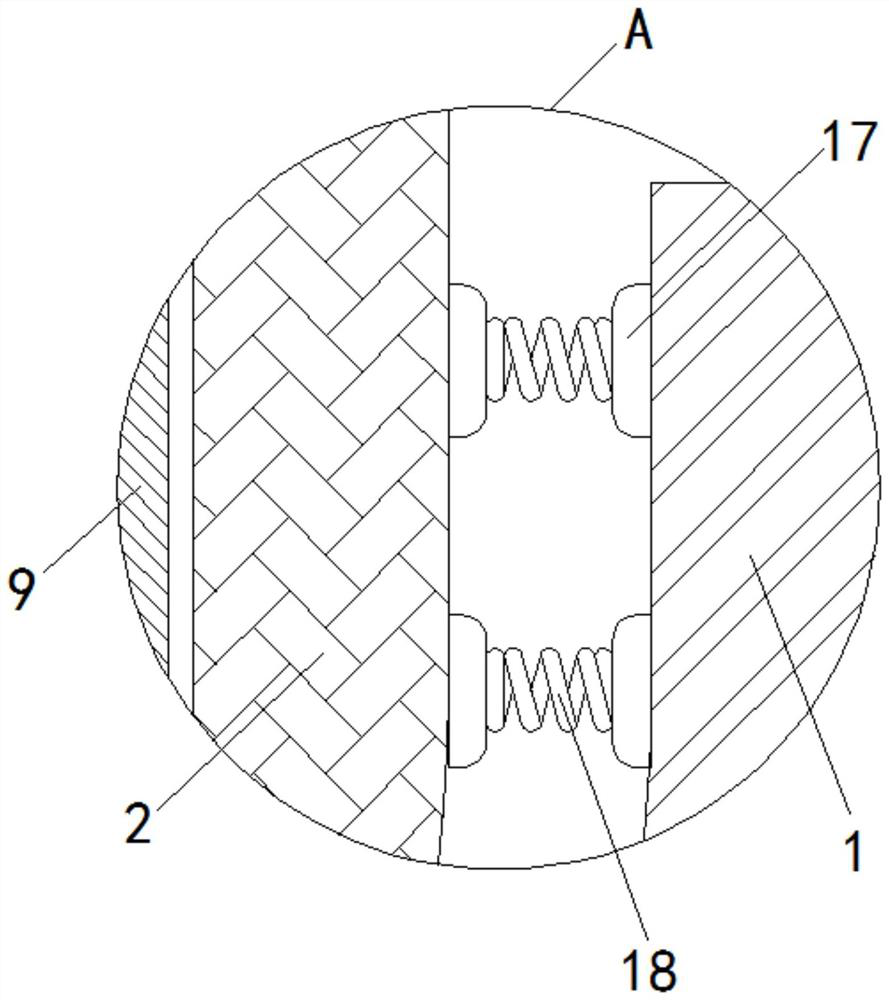

[0024] The invention provides an energy-saving and environment-friendly reaction device for resin production, which includes a housing 1, a main body 2 is installed on the inner wall of the housing 1, and a mounting part 17 is installed on the opposite side of the housing 1 to the main body 2, two A damping spring 18 is installed between the mounting parts 17, and the vibration force is eliminated by the damping spring 18, so that the equipment achieves a good damping effect. The left side of the upper surface of the main body 2 is provided with a feed port 19, By pouring the resin raw material into the equipment along the feed port 19, the inside of the main body 2 heats the resin, the upper side of the main body 2 is provided with a driving mechanism 3, and the lower side of the driving mechanism 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com