Glass cleaning system

A cleaning system and glass technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of detachment from the shelf, the glass cannot be stably fixed, and the glass does not touch the shelf improperly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the embodiments. details as follows:

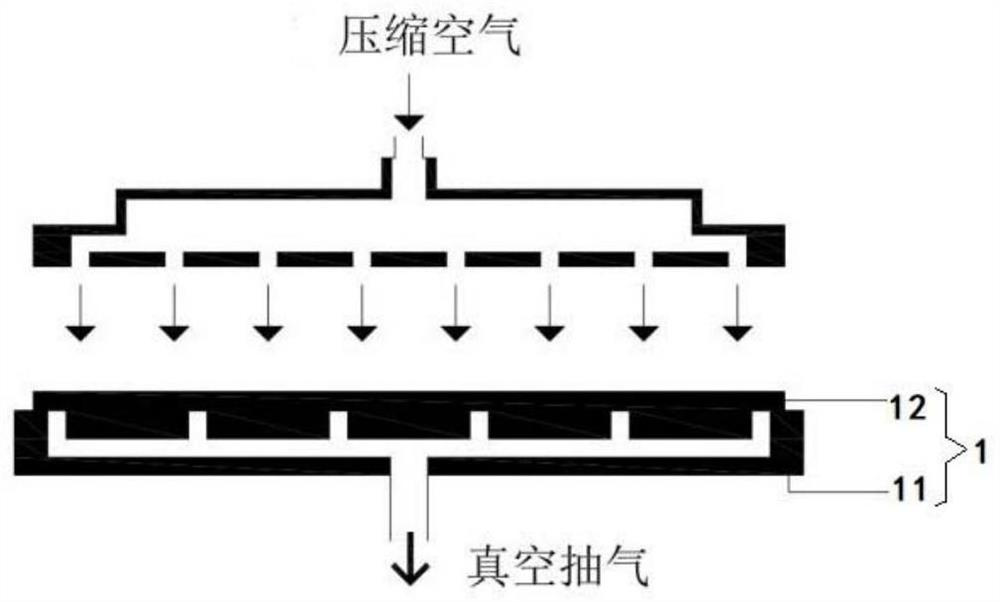

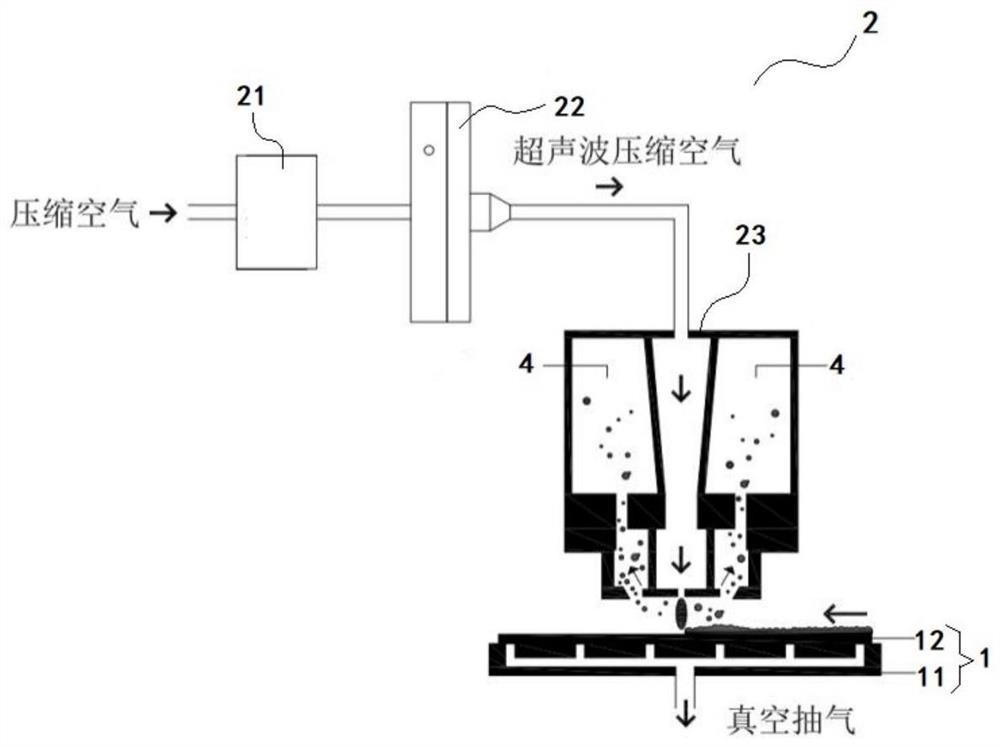

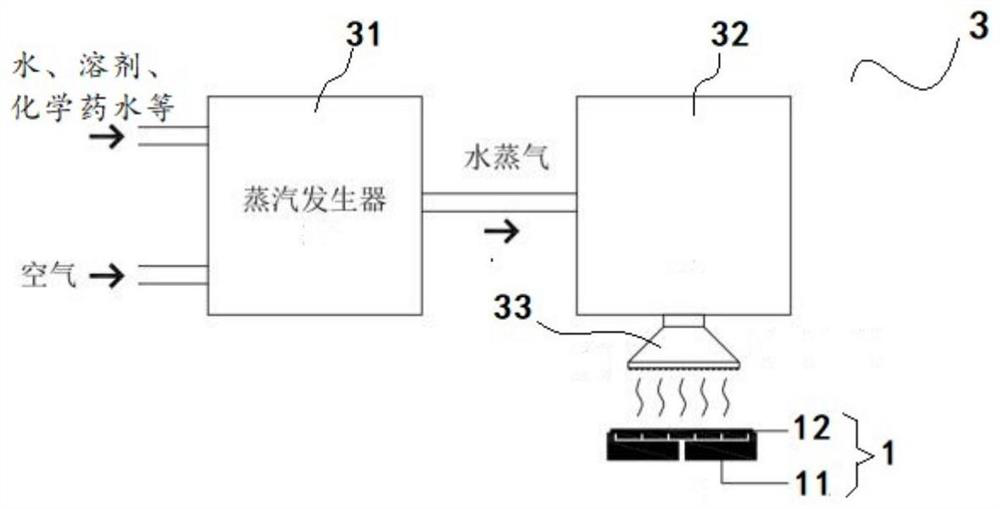

[0023] Such as Figure 1-4 As shown, the glass cleaning system includes a vacuum adsorption module 1, a clean air ultrasonic module 2 and a high-temperature steam ultrasonic module 3, the vacuum adsorption module 1 transmits motion between the clean air ultrasonic module 2 and the high-temperature steam ultrasonic module 3, and the vacuum adsorption module 1 Including a vacuum fixture 11 and a glass 12 to be cleaned, the glass 12 is placed on the vacuum fixture 11, and the glass 12 is kept flat on the vacuum fixture 11; the clean air ultrasonic module 2 includes an air filter 21 connected in sequence, an ultrasonic Generator one 22 and nozzle one 23, when the vacuum adsorption module 1 is transported to the clean air ultrasonic module 2 through the corresponding transmission devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com