Hardware product grinding device for semi-automatic scrap treatment

A semi-automatic, hardware technology, applied in the device of fixed grinding wheel, grinding/polishing safety device, grinding machine, etc., can solve problems such as affecting the health of workers and spreading waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

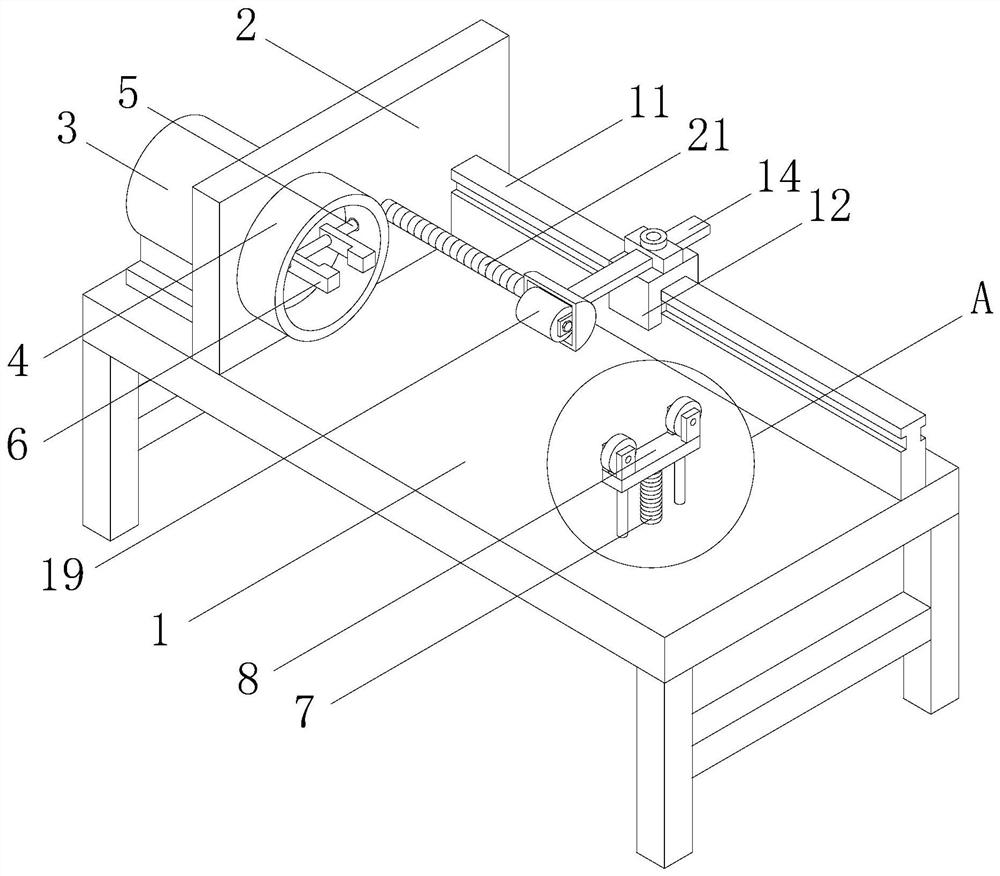

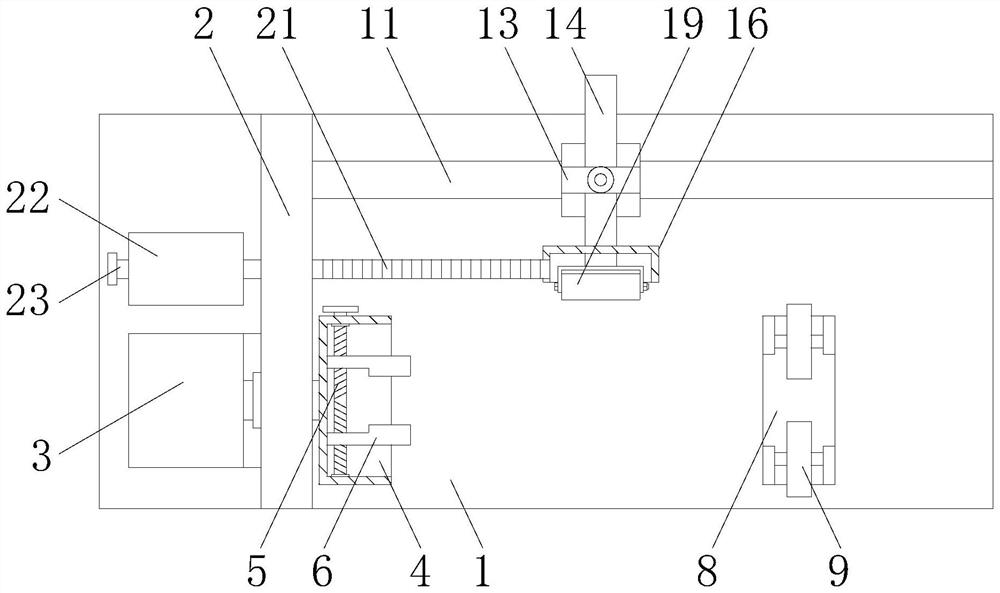

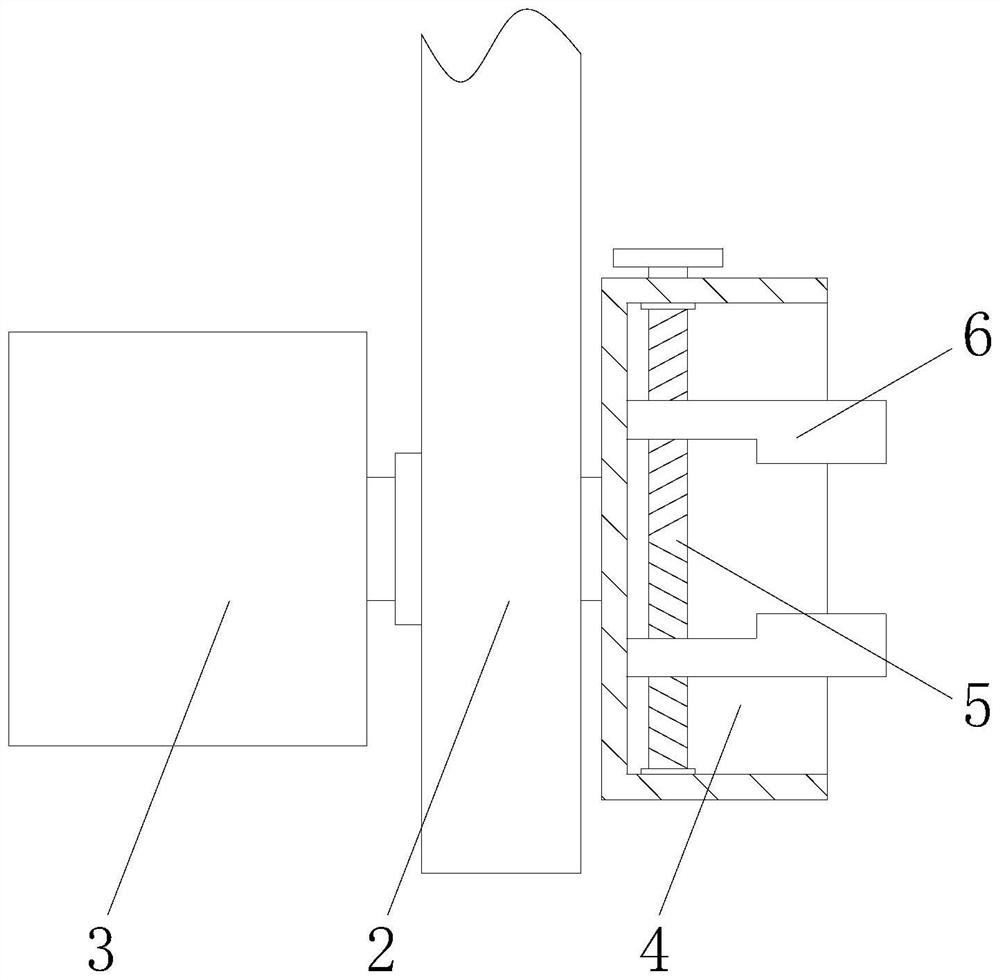

[0029] Example: such as Figure 1-5 As shown, a kind of polishing device for hardware products of semi-automatic waste treatment of the present invention comprises a support platform 1, a support plate 2 is fixedly installed on the top of the support platform 1, and a fixing mechanism is arranged on the support plate 2, and the fixing mechanism is controlled by a stepping motor 3. The support tube 4, the first threaded rod 5 and the splint 6 are composed of two splints 6. The support table 1 is provided with a support mechanism on the side of the support tube 4 away from the support plate 2. The support mechanism consists of a second Threaded rod 7, a horizontal plate 8, two support wheels 9 and two support rods 10 are formed;

[0030] The top of support table 1 is provided with grinding mechanism, and grinding mechanism is made of slide rail 11, slide seat 12, support base 13, connecting plate 14, fixing bolt 15, protective cover 16, support frame 17, mounting screw rod 18, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com