Method and test bench for determining printing parameters of a printing press

A technology of printing presses and parameters, applied in general parts of printing machinery, printing presses, rotary printing presses, etc., can solve the problems of expensive running time of flexographic printing presses and shortening of setting time of flexographic printing presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

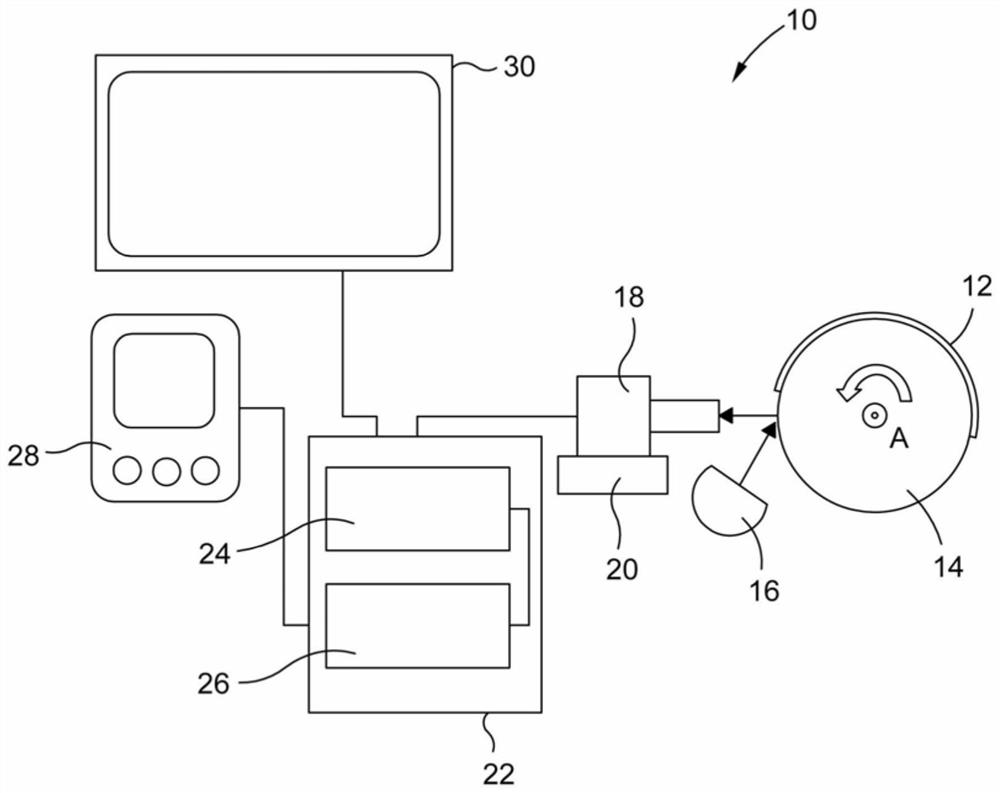

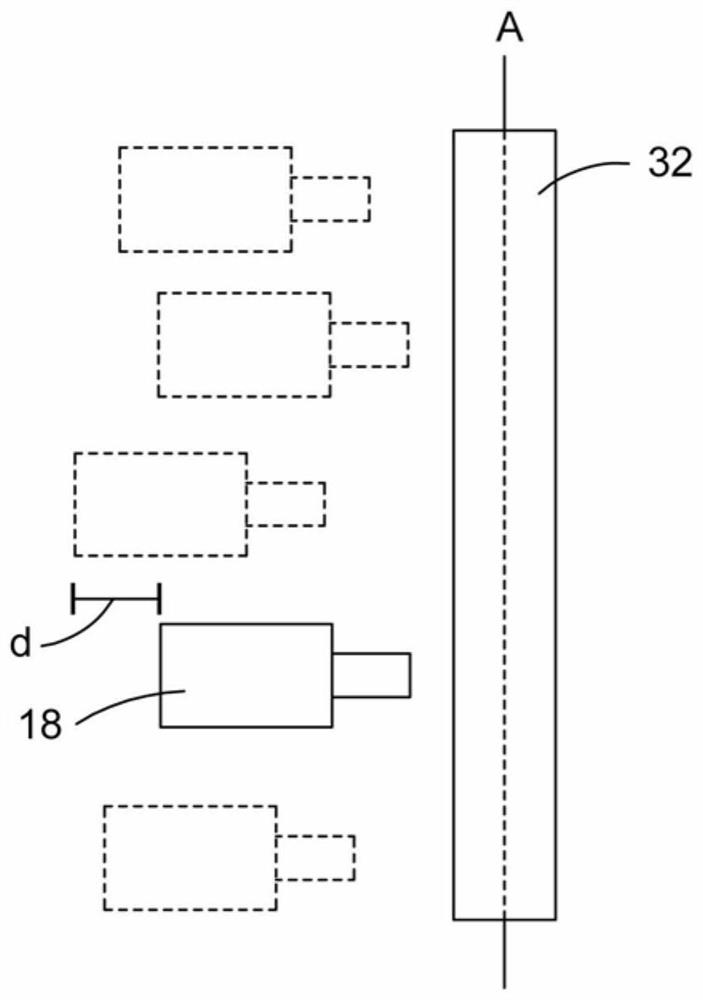

[0064] figure 1 A test stand 10 for determining printing parameters of a printing press (not shown) according to the present invention is shown. In the embodiment shown, the printing press is a flexographic printing press.

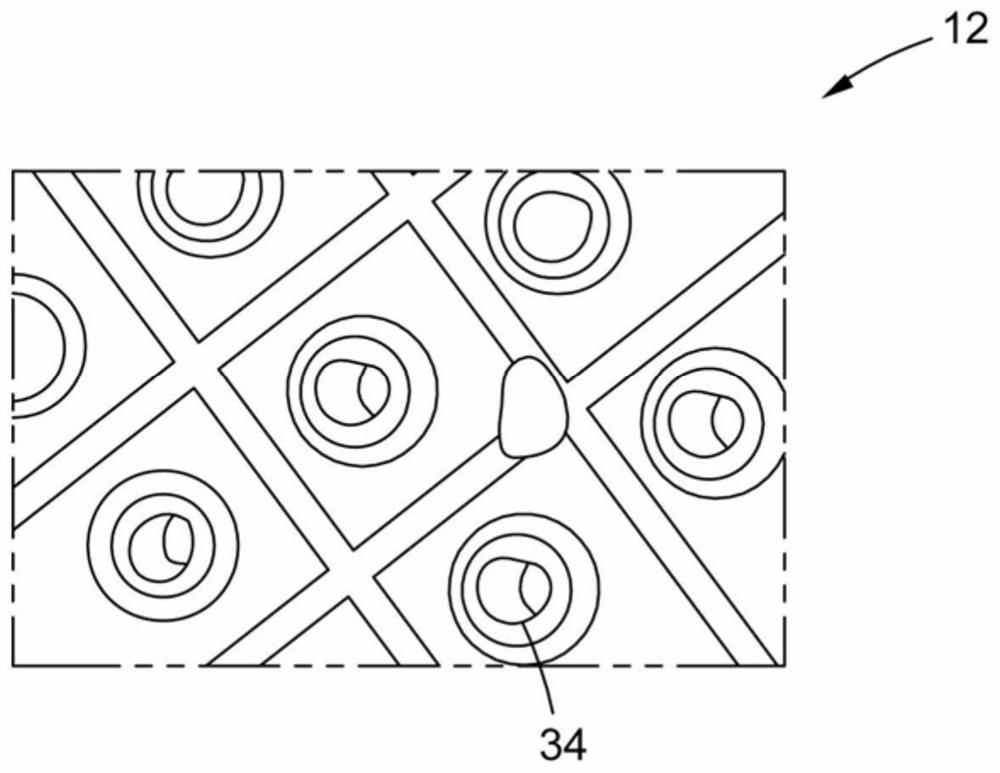

[0065] The test stand 10 is used to test previously prepared printing plates 12 intended for printing in a flexographic printing press. As a result, the printing plate 12 in the embodiment shown here is a cliché. A cliche is usually made individually for each print job from plastic, photopolymer or rubber. The cliche mentioned below generally also includes the printing plate 12 .

[0066] The quality of printing depends on the quality of the respective cliché, as well as the printing parameters used. For optimum printing results, the printing parameters must therefore be adapted to the respective cliche produced.

[0067] The cliche is mounted on a printing cylinder 14, which is then placed in a flexographic printing press together with the cliche for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com