Automobile seat cushion capable of decomposing formaldehyde

A car seat cushion and formaldehyde technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve problems such as easy secondary pollution, easy driving fatigue, and slow removal of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

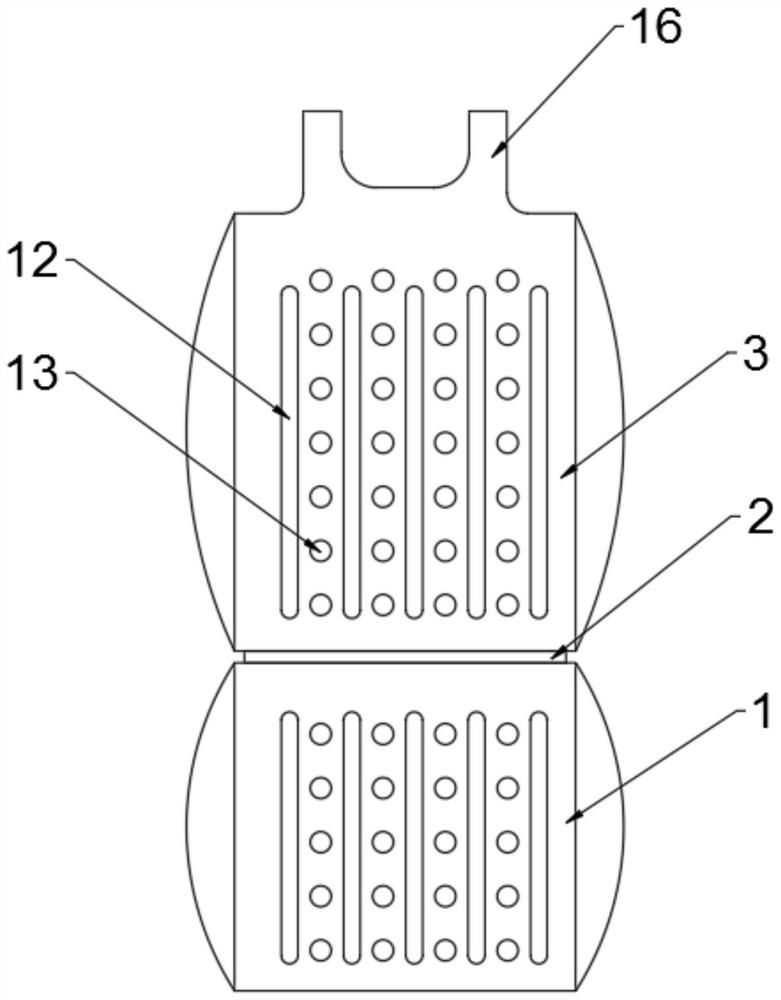

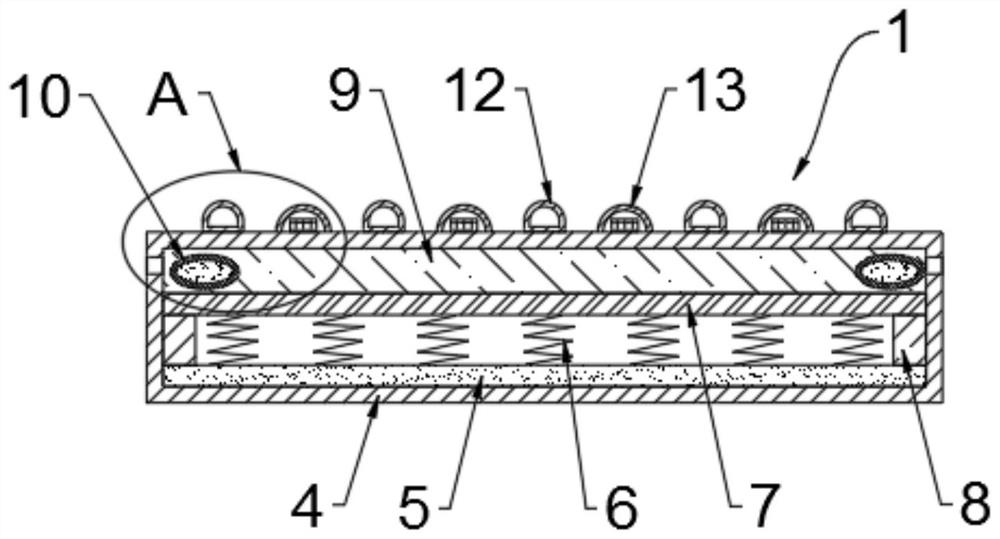

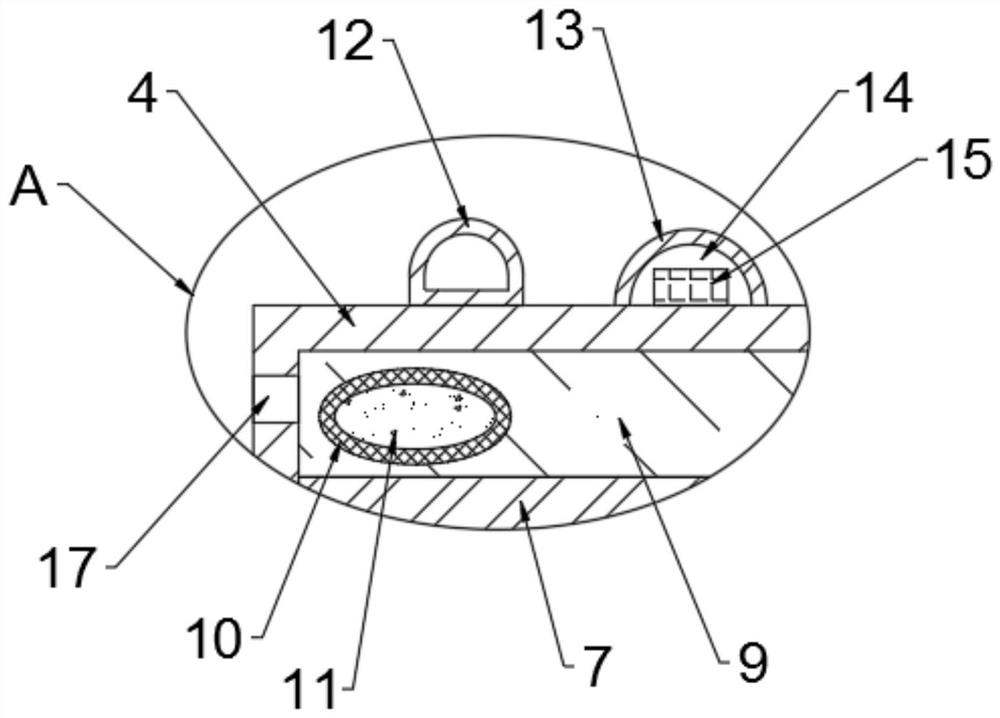

[0021] Embodiment one, by figure 1 , figure 2 and image 3 Given, the present invention includes a bottom cushion 1, a connecting belt 2 and a back cushion 3, one end of the bottom cushion 1 is connected with a back cushion 3 through the connecting belt 2, and both the bottom cushion 1 and the back cushion 3 include a surface cover 4, a heat-melt cotton layer 5, and a spring 6 , gel memory foam layer 7, edge protection sponge 8, elastic sponge layer 9, nylon bag 10 and disassembly sheet 11, the inner lower end of the surface cover 4 is connected with a hot-melt cotton layer 5, and the upper end of the hot-melt cotton layer 5 is evenly connected with a spring 6 The spring 6 can buffer the force of bumps during driving. The upper end of the spring 6 is connected with a gel memory foam layer 7, and the edge between the gel memory foam layer 7 and the hot-melt cotton layer 5 is connected with an edge protection sponge 8. The upper end of the memory foam layer 7 is connected wit...

Embodiment 2

[0022] Embodiment 2, on the basis of Embodiment 1, the decomposing tablet 11 is an active manganese decomposing tablet, which has a strong ability to decompose formaldehyde.

Embodiment 3

[0023] Embodiment three, on the basis of embodiment one, the back cushion 3 is connected with a lanyard 16 in the middle of the upper end, and both ends of the back cushion 3 are connected with a nylon adhesive tape, the lanyard 16 can cover the seat cushion on the car seat, and the nylon adhesive tape The belt can be fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com