Pill dropping machine capable of conveniently adjusting dropping distance and dropping distance adjusting method thereof

A technology of dropping pill machine and distance, which is applied in packaging and other directions, and can solve problems such as high cost, difficult cleaning and maintenance, and inconvenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

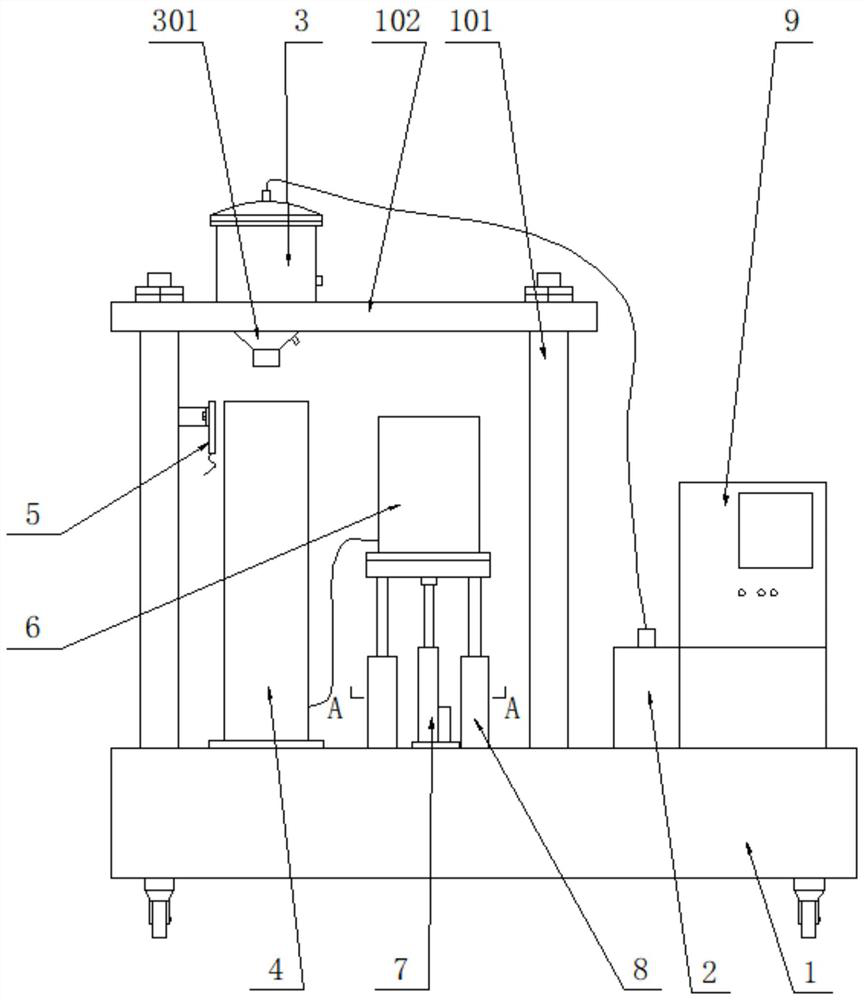

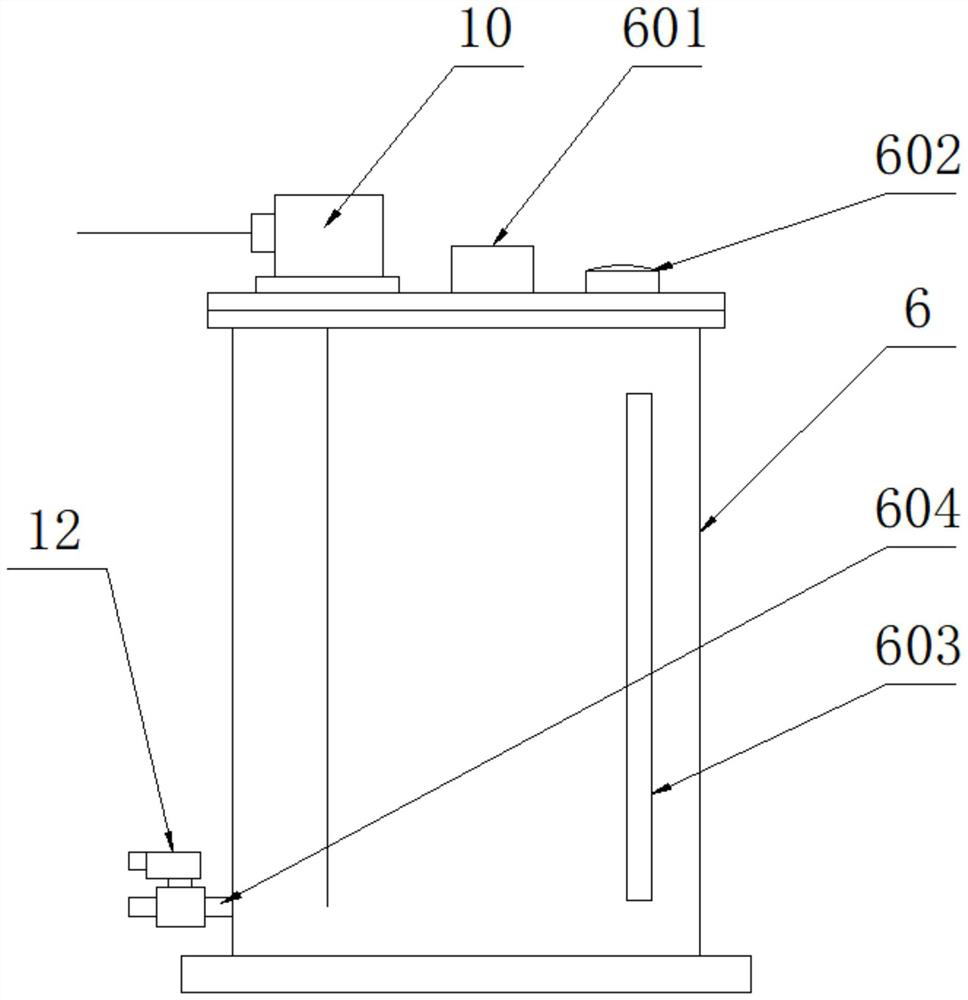

[0035] Example 1, such as Figure 1~3 As shown, a dropping pill machine that is convenient for adjusting the dripping distance includes a frame 1 and a drip tank 3 arranged on the frame 1, a constant pressure air source 2, a cooling column 4 and an electric control box 9, and the frame 1 The top plate 102 is erected on four pillars 101 on the machine base, the drip tank 3 is vertically arranged on the top plate 102, and the drip head 301 directly below the drip tank 3 faces the cooling column 4. The constant-pressure air source 2 and the electric control box 9 are arranged at one end of the base, and the compressed air provided by the constant-pressure air source 2 is communicated to the drip tank 3 top cover through the air pipe. The electric control box 9 controls the electrical operation of the dripping pill machine of the present invention. The dropping pill machine that is convenient to adjust the dripping distance of the present invention also includes a liquid storage ...

Embodiment 2

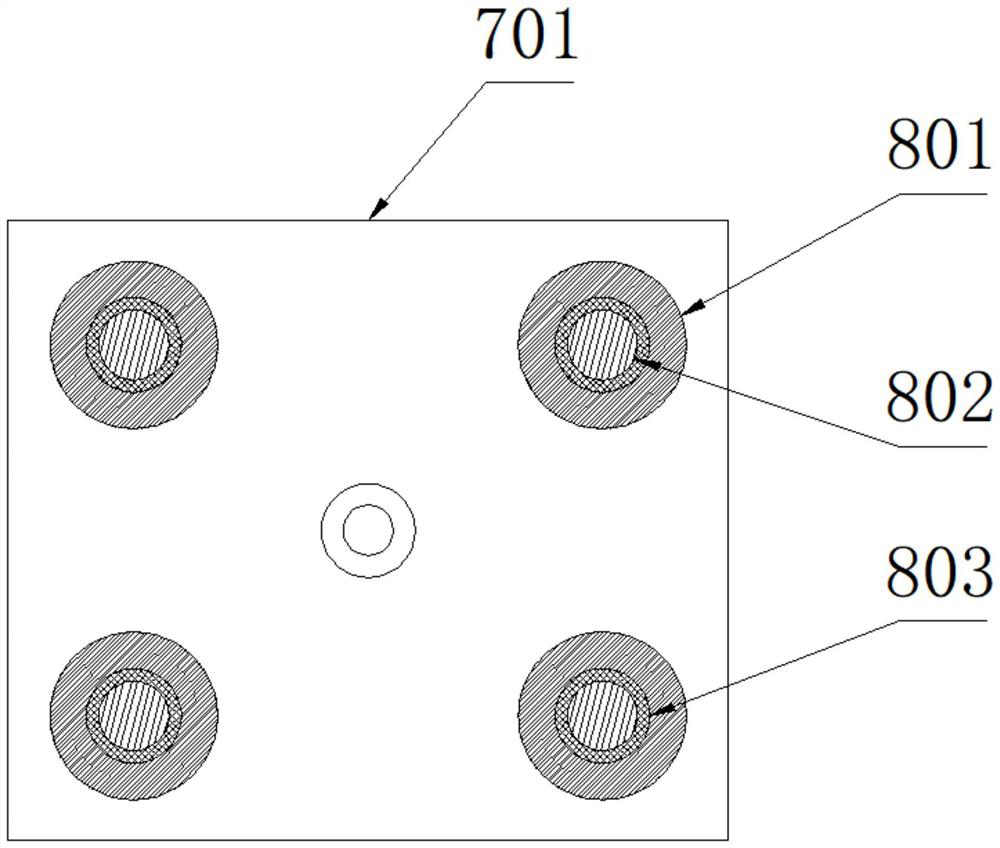

[0047] Example 2, such as Figure 4~6 As shown, on the basis of the above-mentioned embodiment 1, the number of combinations of the drip tank 3 and the cooling column 4 is increased to constitute this embodiment. The number of combinations of drip tanks 3 and cooling columns 4 is six groups, and the arrangement is two rows and three rows.

[0048] By increasing the number of combinations of dripping tanks 3 and cooling columns 4, adding dripping stations to form a six-station constant pressure source dropping pill equipment, each dripping head 301 operates simultaneously, greatly improving production efficiency.

[0049] Specifically, as Figure 6 As shown, on the gas path, the constant pressure gas source 2 is output to the distributor 13, and the first air gauge 201 is installed on the output pipeline of the constant pressure gas source 2, and the output end of the distributor 13 is connected to six branches, and the six branches Road is connected to drip tank 3 top covers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com