System for efficiently treating acrylonitrile wastewater and combined process thereof

A technology of acrylonitrile wastewater and combined process, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of nitrogen and phosphorus removal, high cost, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

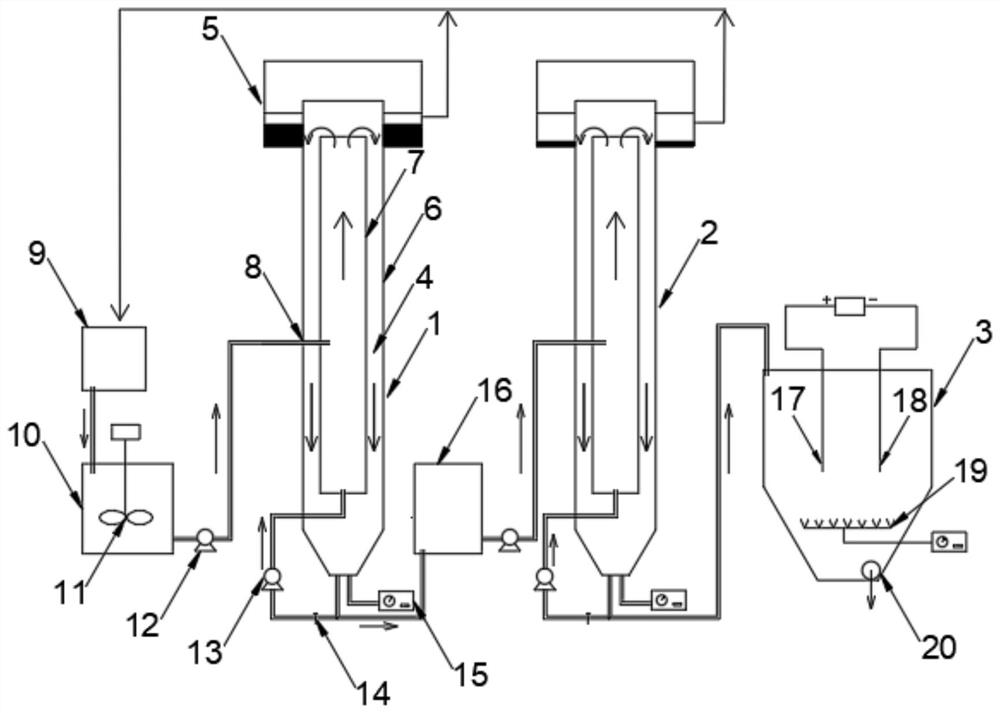

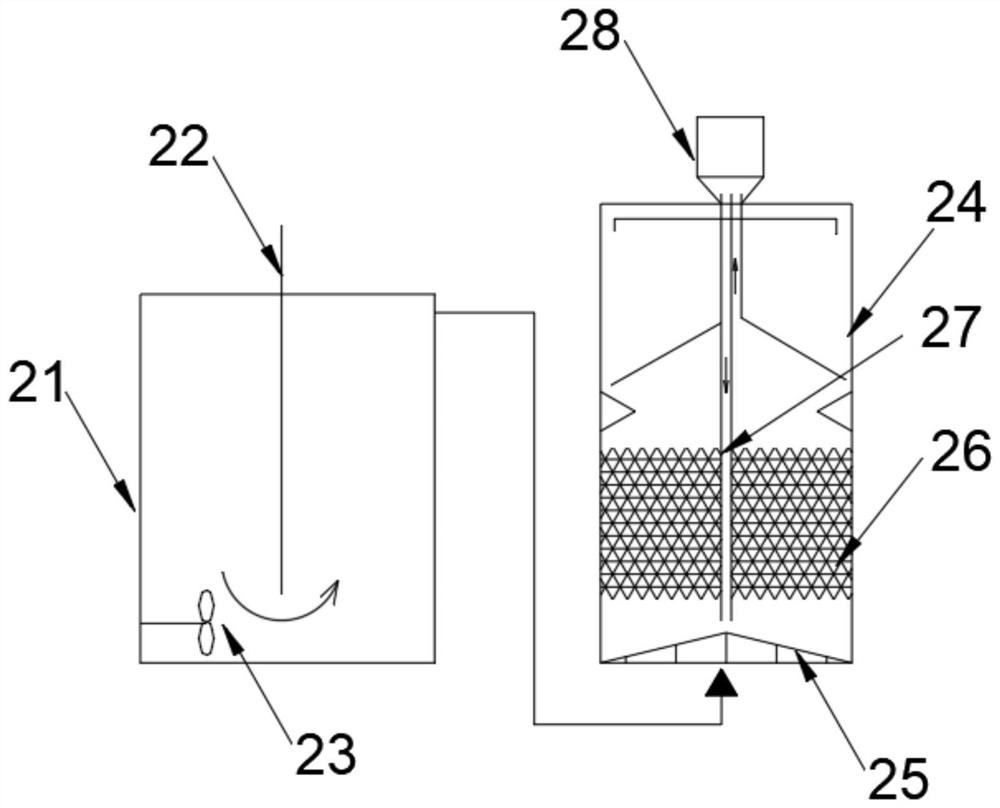

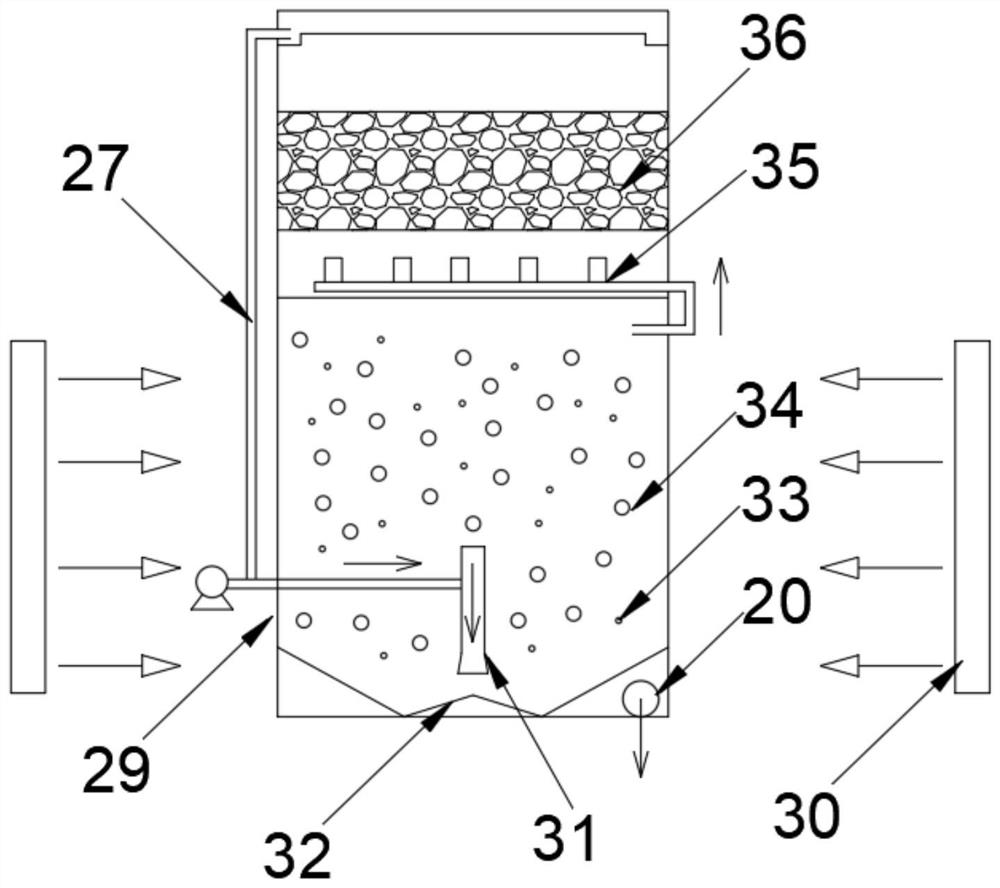

[0037] Such as Figure 1-3 As shown, a system for efficiently treating acrylonitrile wastewater includes a primary circulation air flotation column 1, a secondary circulation air flotation column 2, a high-efficiency electrolytic cell 3, a chemical tank 9, a water inlet tank 10, and a hydrolytic acidification pool 21 , anaerobic fixed film reactor 24, photobiology-fixed bed integrated reactor 29, the first-stage circulation type air flotation column 1 and the second-stage circulation type air flotation column 2 are all connected with the medicine box 9, and the medicine box 9 is connected with the water inlet The tank 10 communicates, the water inlet tank 10 communicates with the water inlet 8 of the first-stage circulation air flotation column 1 through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com