Low-cost coal dust suppressant and preparation method thereof

A dust suppressant and low-cost technology, applied in the field of low-cost coal dust suppressant and its preparation, can solve the problem of high cost of coal dust suppressant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A low-cost coal dust suppressant comprises the following components by weight: 1.5 parts of powder and 98.5 parts of water.

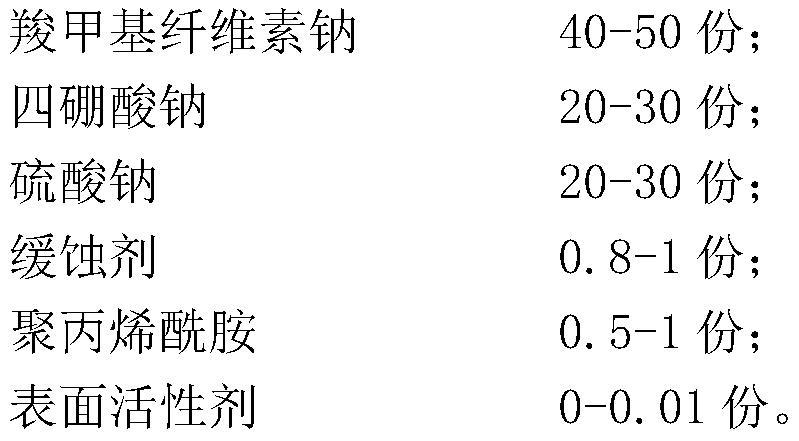

[0039] Described pulvis is calculated by weight component:

[0040]

Embodiment 2

[0042] A low-cost coal dust suppressant comprises the following components by weight: 1 part of powder and 99 parts of water.

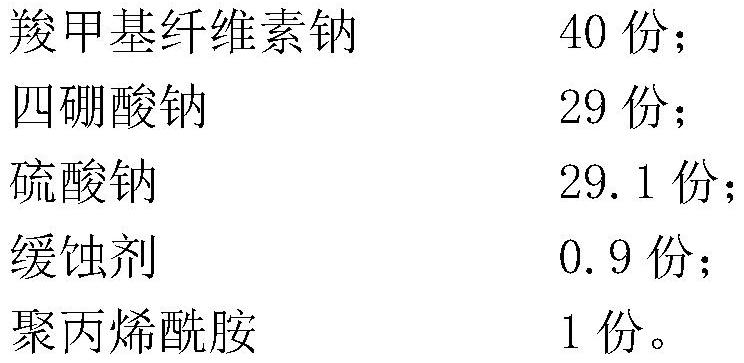

[0043] Described pulvis is calculated by weight component:

[0044]

[0045] In the second aspect of the embodiment of the present application, a method for preparing a low-cost coal dust suppressant is also provided. The method for preparing the low-cost coal dust suppressant is used to prepare the low-cost coal dust suppressant provided in the first aspect of the embodiment of the application. Dust agent, described method comprises the following steps:

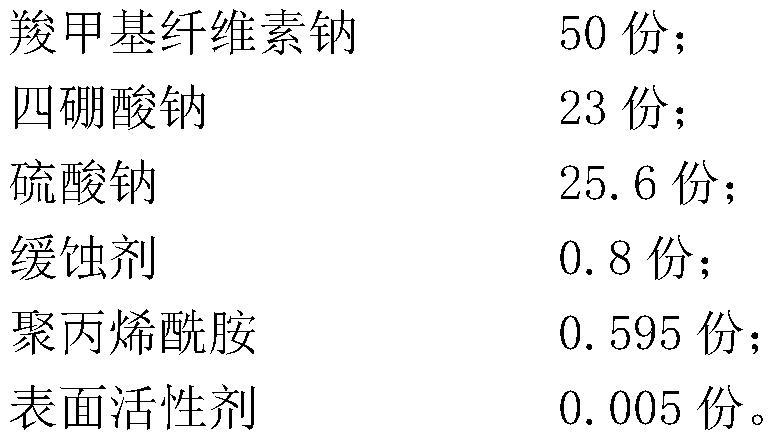

[0046] At room temperature, add 40-50 parts of sodium carboxymethylcellulose, 0-0.01 parts of surfactant, 0.8-1 part of corrosion inhibitor, 0.5-1 part of polyacrylamide, 20-30 parts of Sodium sulfate, 20-30 parts of sodium tetraborate, and fully stirred for 30 minutes to obtain a powder.

[0047] Add 0.8-1.5 parts of the powder into 98.5-99.2 parts of water according to the ratio of parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com