Novel middle pipe structure for mounting ball bearing

A technology of ball bearing and tube structure, applied in the direction of rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve the problems of reducing fan life, multi-production equipment, and unable to meet the fixed needs of ball bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

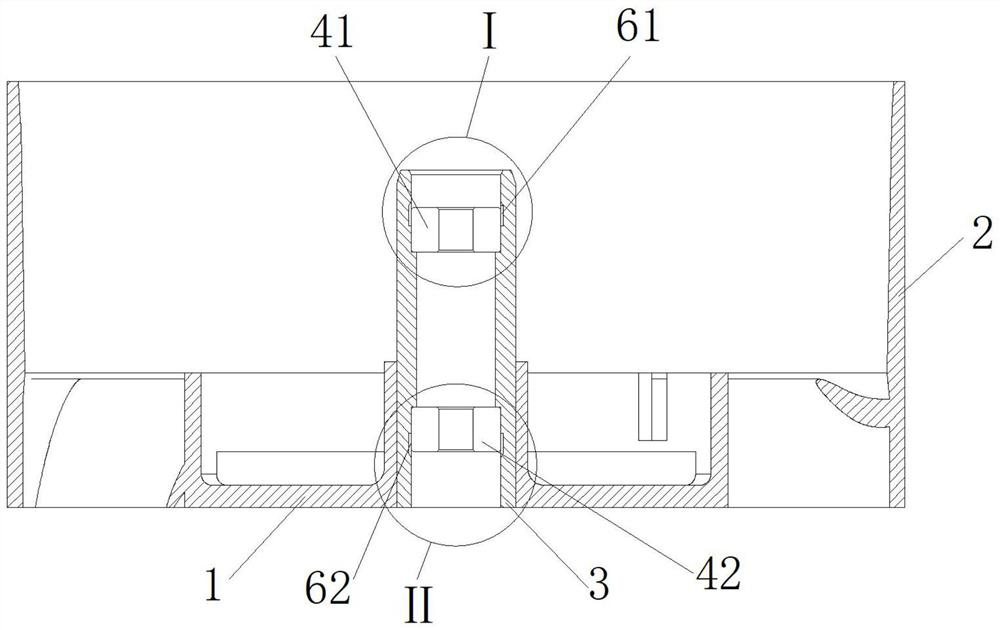

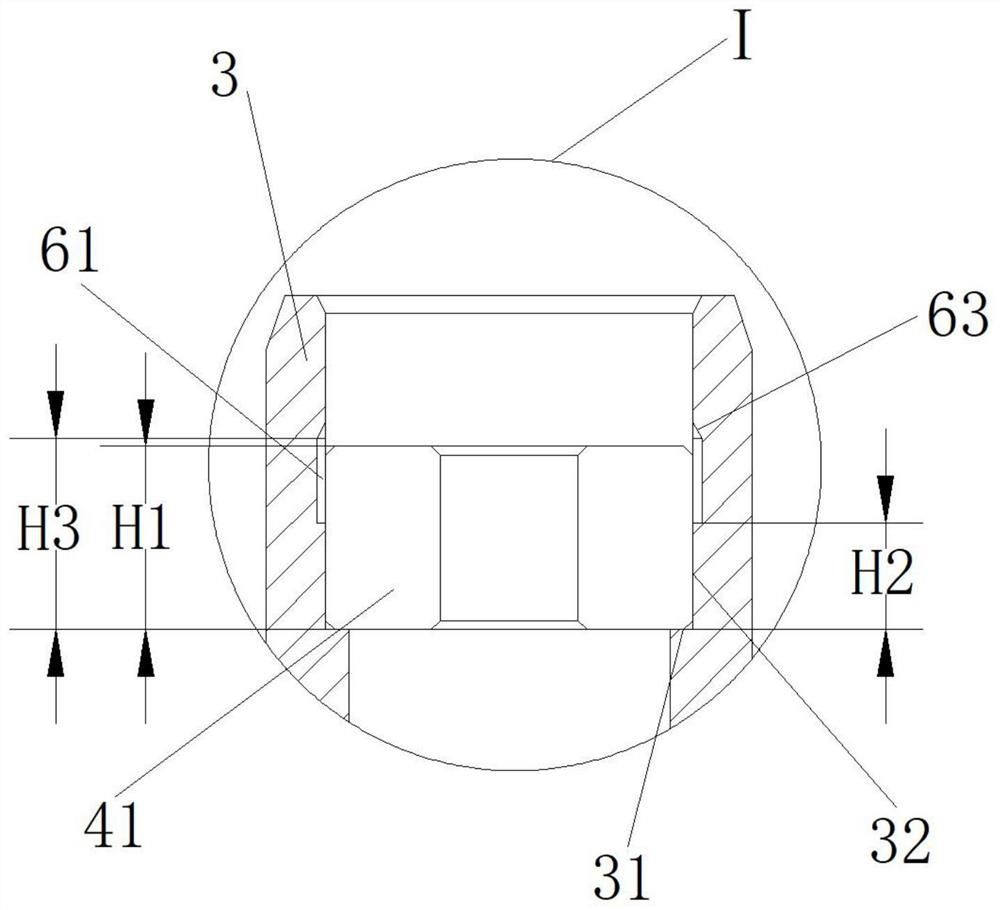

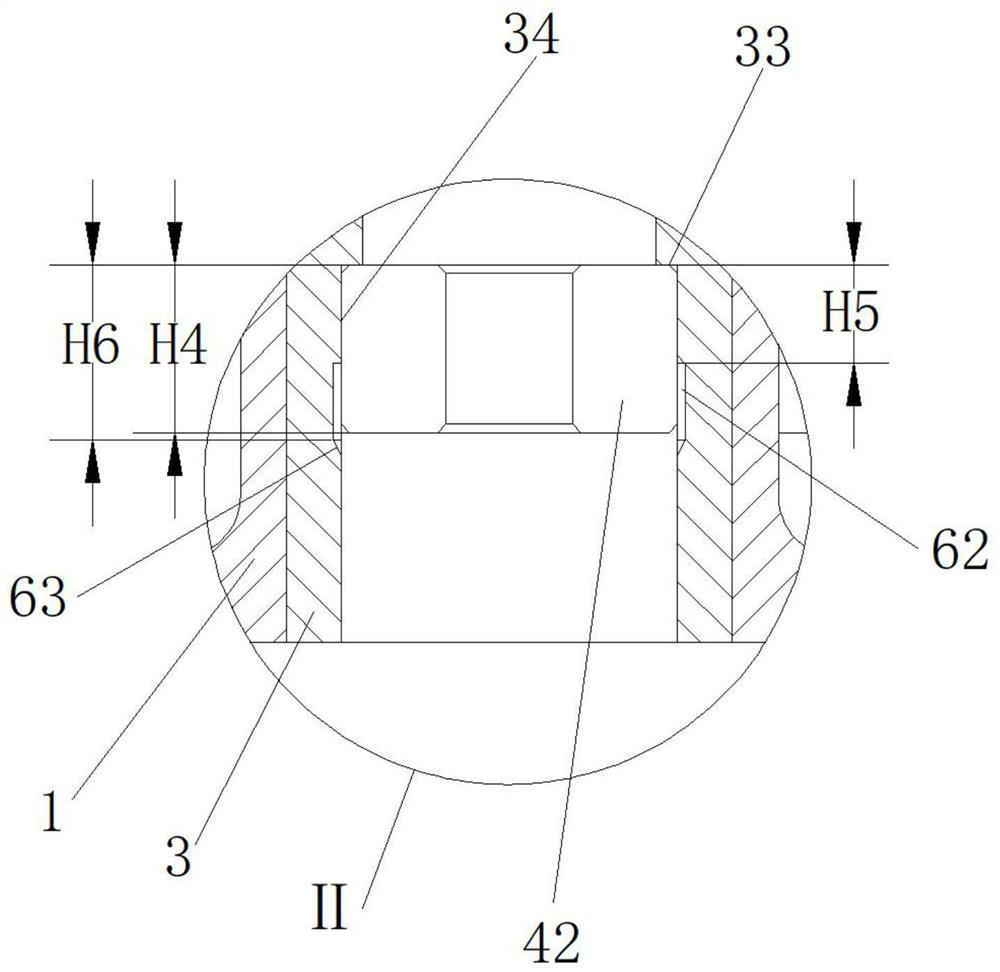

[0042] Please refer to Figure 1 to Figure 3, the present invention provides a new middle tube structure for installing ball bearings, including a middle tube 3, the middle tube 3 is installed inside the stator hub 1, and the stator hub 1 is installed inside the outer frame 2, and the One end of the middle pipe 3 is fixedly equipped with a first ball bearing 41 through adhesive bonding, and the other end is fixedly equipped with a second ball bearing 42 through adhesive bonding. The first ball bearing 41 and the second ball bearing 42 are fixedly installed on the middle pipe 3 by adhesive bonding.

[0043] One end of the middle tube 3 is provided with a first axial support ring end face 31 and a first radial support ring face 32, and the first axial support ring end face 31 is axially supported by the first ball bearing 41, so The first radial support ring surface 32 is radially supported by the first ball bearing 41, the first radial support ring surface 32 is provided with ...

Embodiment 2

[0054] Please refer to Figure 4 , Embodiment 2 of the present invention provides a middle pipe with a liquid injection groove and a groove structure. The difference from Embodiment 1 is that only the first groove and the second groove are changed to the first helical groove 71 and the second spiral groove 72, only the shape of the groove containing the adhesive is changed, so that the force uniformity of the first ball bearing 41 and the second ball bearing 42 is further improved.

[0055] Such as Figure 5 As shown, the first groove is a first helical groove 71, the axial height of the first helical groove 71 is higher than the height of the first ball bearing 41, and the first helical groove 71 is higher than the first A part of the ball bearing 41 can be used as a liquid injection tank for the adhesive, and a connected chamber is formed between the first spiral groove 71 and the first ball bearing 41, and an adhesive is installed inside the chamber. Bonding agent, the ad...

Embodiment 3

[0060] Please refer to Figure 7 , the third embodiment of the present invention provides a middle pipe with a liquid injection groove and a groove structure, the difference from the first embodiment is that only the first groove and the second groove are changed into a third annular groove 81 And the fourth annular groove 82, and move the position to the middle position of the bearing, the shape of the groove containing the adhesive remains unchanged, and the third annular groove 81 and the fourth annular groove 82 are added with adhesive. The first liquid injection groove 91 and the second liquid injection groove 92 make the stress uniformity of the first ball bearing 41 and the second ball bearing 42 further improved compared with the first embodiment.

[0061] Please refer to Figure 8 , the first groove is a third annular groove 81, the third annular groove 81 is located in the middle of the first ball bearing 41, and the first radial support annular surface 32 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com