Elastic supporting structure for LNG double-wall pipes

An elastic support, double-wall pipe technology, applied in the field of support frame, can solve the problems of inconvenient disassembly and repair, hidden dangers, fracture failure of the welded part of the LNG double-wall pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

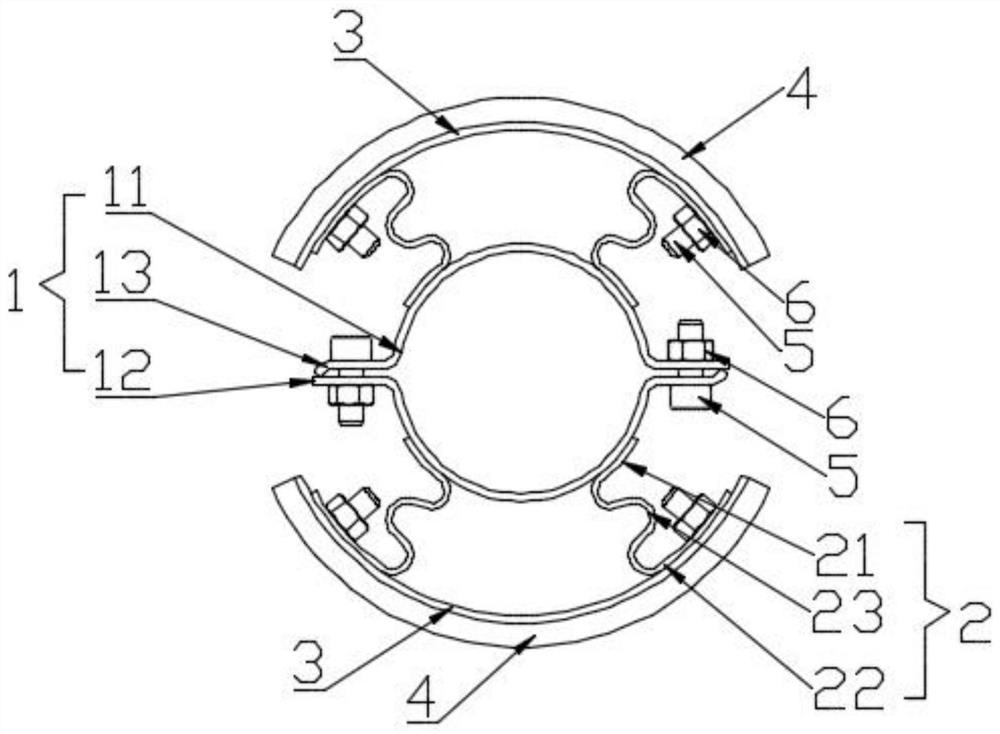

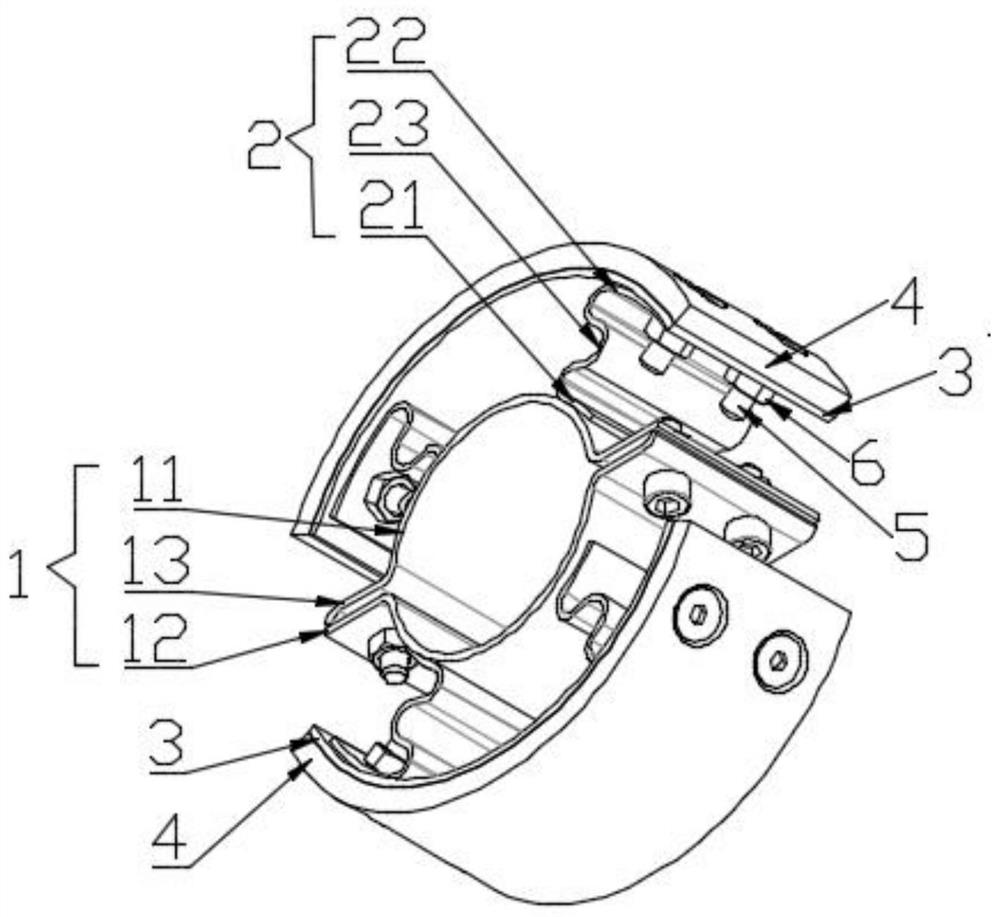

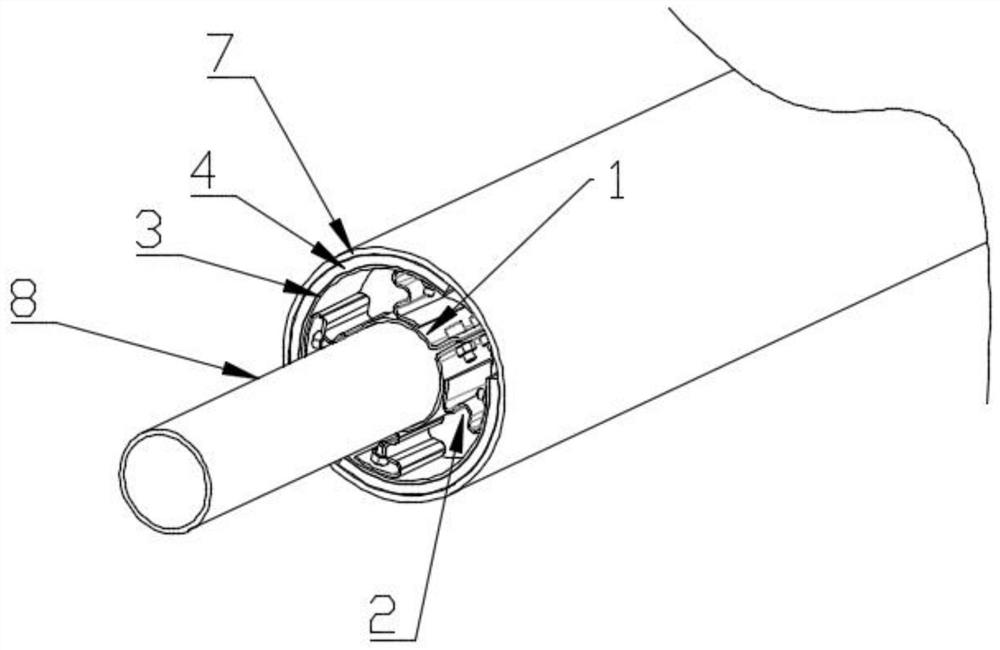

[0030] Such as Figure 1-3 As shown, the elastic support structure includes an inner pipe snap ring part 1, a spring part 2, an outer snap ring 3, and a Teflon guide block 4. The outer snap rings 3 are arranged symmetrically and cooperate with each other. The outer snap rings 3 in this embodiment are arc-shaped; and connected with the inner side wall of the LNG outer pipe 7, the Teflon guide block 4 is connected to the outer snap ring 3 through the bolt 5 and the nut 6 in this embodiment. One end of the spring member 2 is connected with the outer snap ring 3 through a bolt 5 and a nut 6 , and the other end is welded on the inner pipe snap ring member 1 .

[0031] Such as Figure 1-3 As shown, the inner pipe snap ring part 1 includes an inner snap ring 11 , a connecting block 12 and a compression buffer piece 13 . Specifically, the inner snap ring 11 is semicircular, and the inner snap ring 11 and the outer snap ring 3 are coaxially arranged; there are two inner snap rings 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com