Fluorine-free super-hydrophobic flexible photo-thermal film and preparation method thereof

A super-hydrophobic, flexible, photothermal technology, applied in the direction of repelling fibers, pigment-containing coatings, coatings, etc. to liquids, which can solve the feasibility of restricting industrial production, difficult to degrade organic pollutants, and the use of flexible substrates. problem, to achieve the effect of short preparation cycle, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention firstly provides a method for preparing a fluorine-free superhydrophobic flexible photothermal film, comprising the following steps:

[0038] S1. Dispersing the photothermal material in an organic solvent to obtain a first dispersion;

[0039] S2. Adding a silane coupling agent to the first dispersion for dispersion to obtain a second dispersion;

[0040] S3, coating the second dispersion liquid on the surface of the flexible substrate and performing curing treatment.

[0041] In the present invention, the photothermal material is dispersed in the organic solvent first, and then the silane coupling agent is directly added for reaction. On the one hand, the addition of the silane coupling agent can reduce the surface energy of the coating and increase the hydrophobicity; The adhesion between nanomaterials and the substrate improves the mechanical strength of the coating; during the coating process, photothermal materials can spontaneously aggregate...

Embodiment 1

[0053] The preparation method of the fluorine-free superhydrophobic flexible photothermal film of this embodiment comprises the following steps:

[0054] S1. Add 50 mg of titanium nitride nanoparticles to 10 mL of ethyl acetate, and sonicate for 10 minutes to obtain the first dispersion;

[0055] S2. Add 50 mg of PDMS to the first dispersion, and sonicate for 30 minutes to obtain the second dispersion;

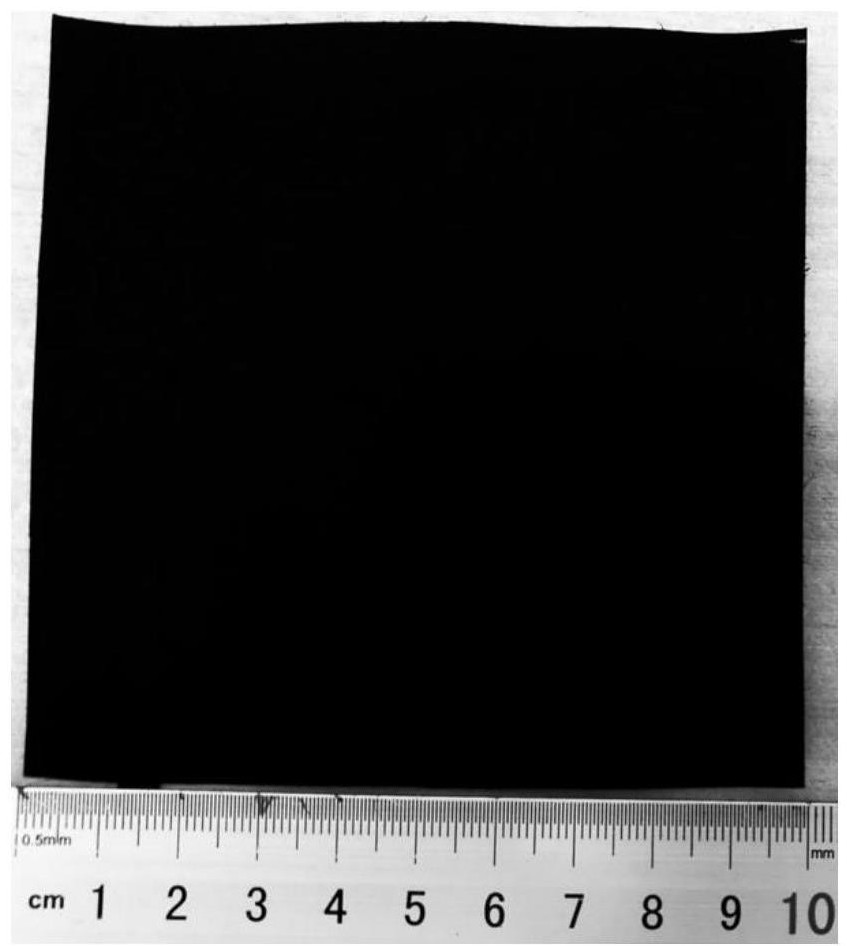

[0056] S3, the second dispersion liquid is added in the spray gun, under the condition that the air pressure of the spray gun is 0.5MPa and the distance is 15cm, use the spray gun to carry out the filter paper surface spray treatment, the size of the filter paper is 100cm 2 ; After spraying, under the condition of 100°C, cure for 1.5 hours to obtain a fluorine-free superhydrophobic flexible photothermal film, such as figure 1 shown.

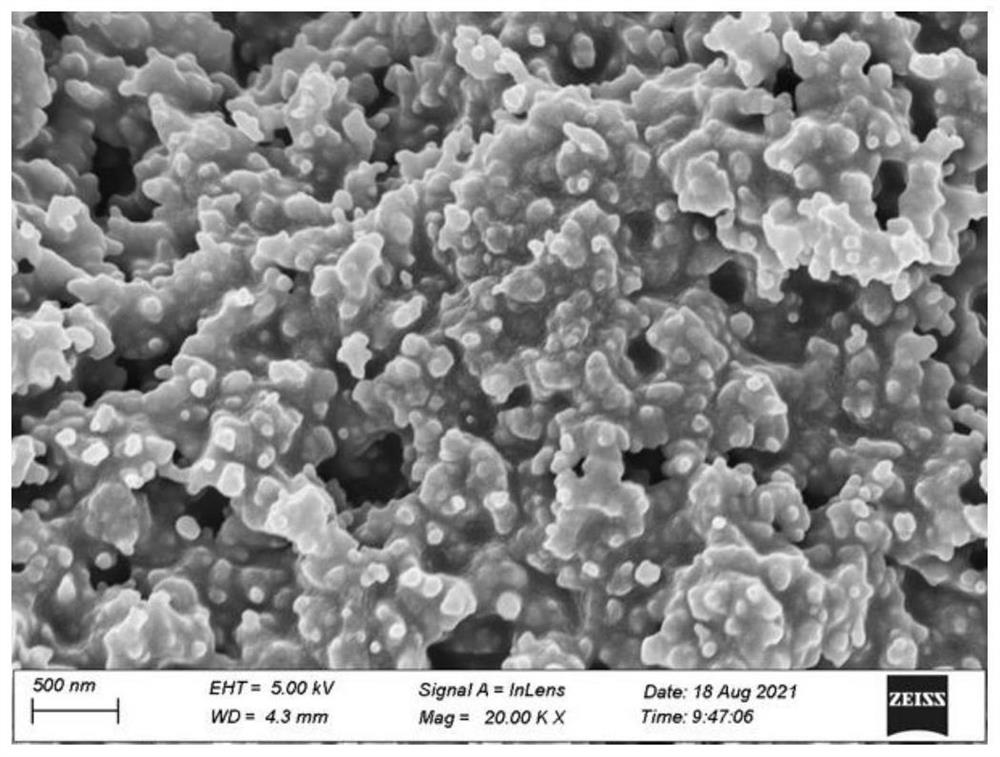

[0057] A series of tests were carried out on the fluorine-free superhydrophobic flexible photothermal film obtained in Example 1: figure 2 F...

Embodiment 2

[0059] The preparation method of the fluorine-free superhydrophobic flexible photothermal film of this embodiment comprises the following steps:

[0060] S1. Add 600mg of titanium nitride nanoparticles to 300mL of ethyl acetate, and sonicate for 10 minutes to obtain the first dispersion;

[0061] S2. Add 120 mg of PDMS to the first dispersion, and sonicate for 30 minutes to obtain the second dispersion;

[0062] S3, the second dispersion liquid is added in the spray gun, under the condition that the air pressure of the spray gun is 0.5MPa and the distance is 15cm, use the spray gun to carry out the filter paper surface spray treatment, the size of the filter paper is 100cm 2 ; After spraying, under the condition of 100°C, cure for 1.5 hours to obtain a fluorine-free superhydrophobic flexible photothermal film.

[0063] A series of tests were carried out on the fluorine-free superhydrophobic flexible photothermal film obtained in Example 2: Figure 4 For coating surface measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com