Calibrating device of articulated arm type coordinate measuring machine

A technology of coordinate measuring machines and verification devices, which is applied in the direction of measuring devices and instruments, and can solve the problems of many operation steps, lack of richness, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

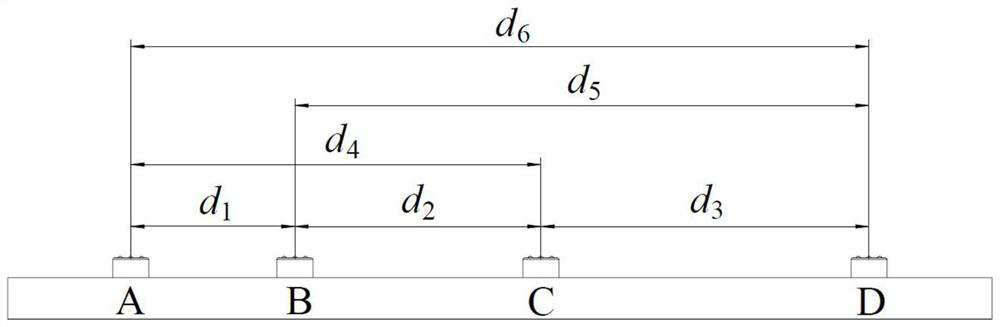

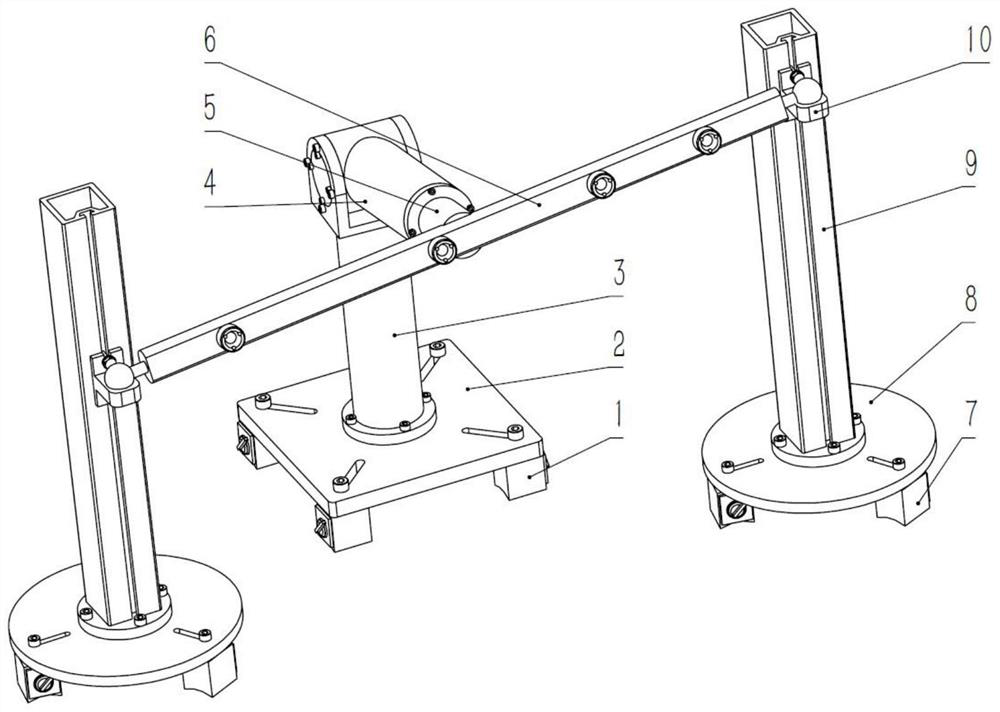

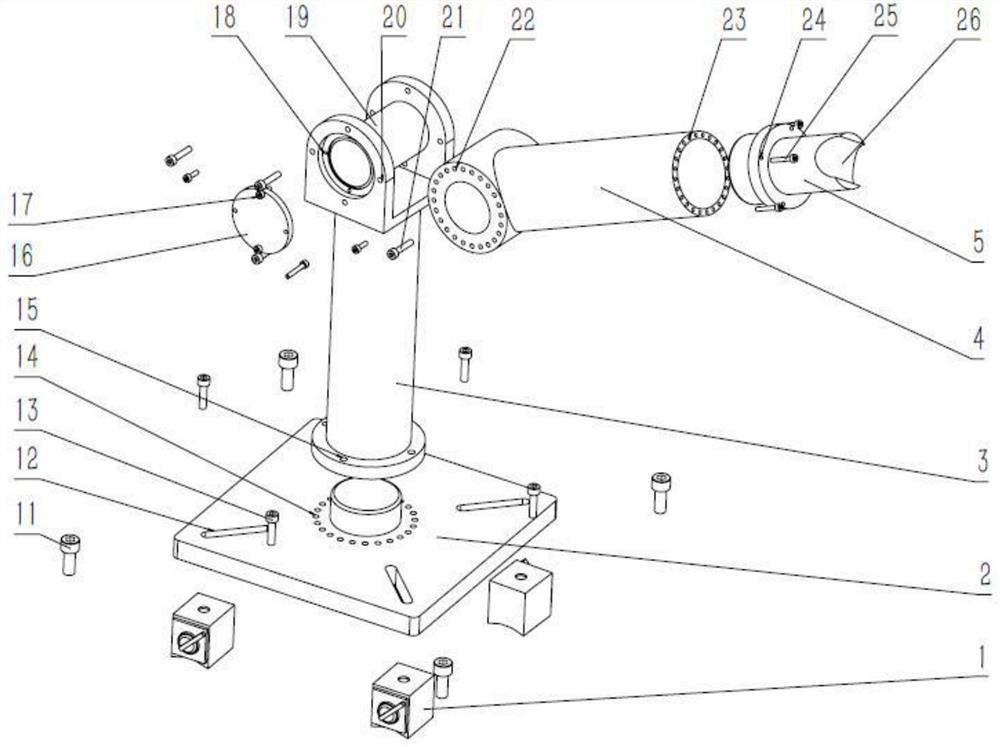

[0027] Embodiment 1: as Figure 1-9 As shown, a verification device for an articulated arm type coordinate measuring machine includes a magnetic suction seat I1, a base 2, a joint cylinder 3 for one axis, a cylinder 4 for two joints, a connecting rod 5 at the end, a standard measuring rod 6, a magnetic force Suction seat II7, support base plate 8, support column 9, auxiliary support part 10; the bottom of the base 2 is connected to the magnetic suction seat I1, the lower part of the one-axis joint cylinder 3 is connected to the upper surface of the base 2, and one end of the two-axis joint cylinder 4 It is connected with the upper part of the one-axis joint cylinder 3, one end of the end connecting round rod 5 is connected with the other end of the two-axis joint cylinder 4, the standard measuring rod 6 is connected with the other end of the end connecting round rod 5, and the standard measuring rod 6 is provided with a cone along the longitudinal direction. Platform 29, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com