Tunable directional generation on-chip diffraction-free beam device and implementation method thereof

A technology of non-diffraction beams and implementation methods, applied in the field of on-chip devices, can solve problems such as unadjustable and controllable, strong background interference, and insufficient degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically described below by taking a device for generating multiple non-diffracting beams on a chip with tunable orientation and its implementation method as an example.

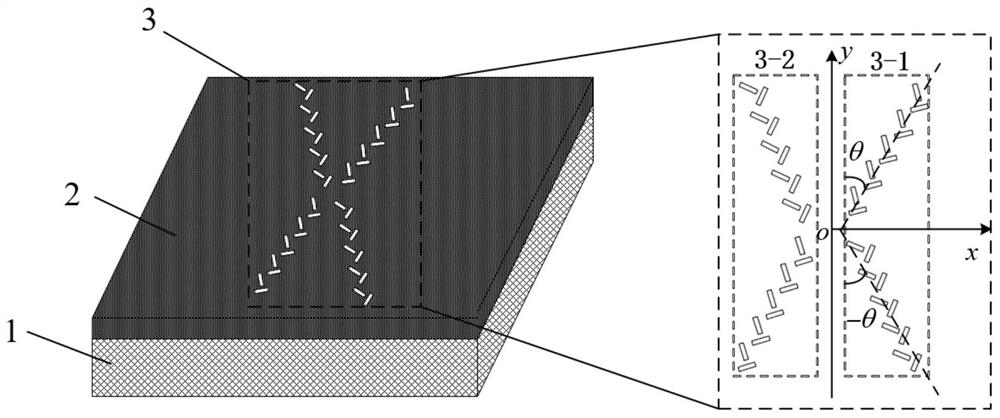

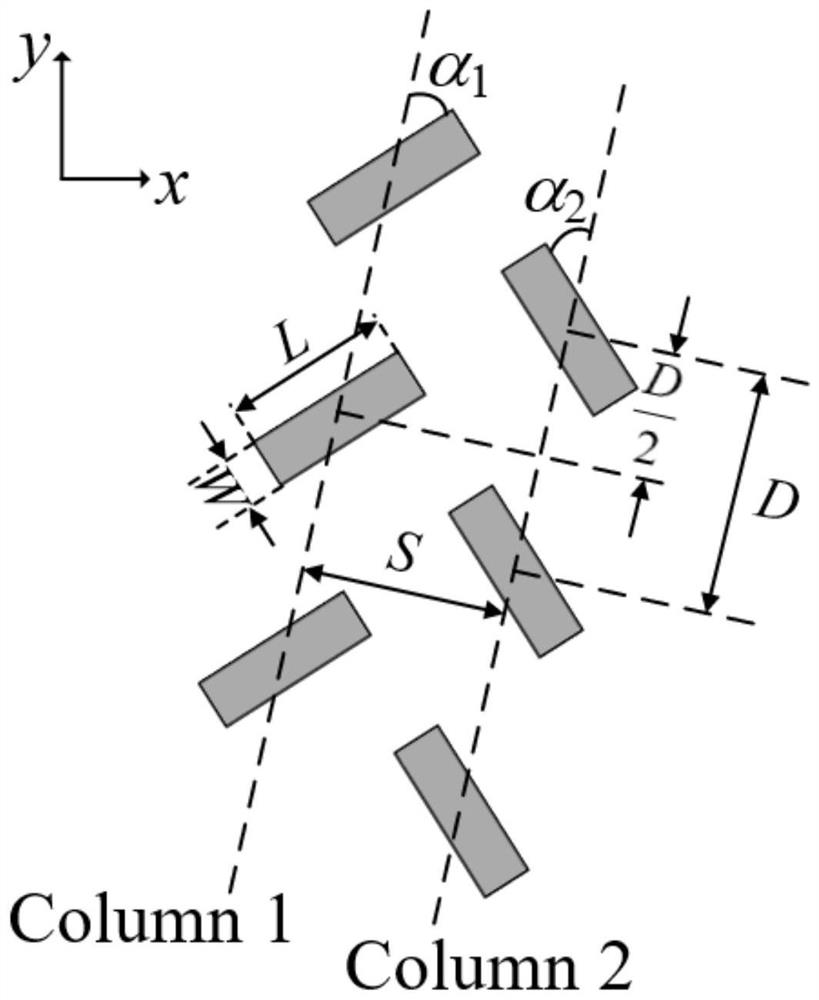

[0027] Such as figure 1 As shown, in this embodiment, the device capable of generating multiple on-chip non-diffracting beams with tunable orientation includes a silicon dioxide substrate 1, a nano-gold film 2, and nanostructure arrays 3-1, 3-2. The basic structures of the nanostructure arrays 3-1 and 3-2 are a pair of rectangular nanoslots. The width of a single rectangular nano-groove is 40nm, the length is 200nm, and its rotation angle is 45 degrees or -45 degrees, etched on the nano-gold film 2 with a height of 200nm, and the nano-gold film 2 is located on the silicon dioxide substrate , the lateral distance between the same pair of rectangular nanoslots is λ spp / 4, the longitudinal distance is 150nm, the structure is as figure 2 shown. For left-handed circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com