A method for removing nitrate from paper-making reconstituted tobacco leaves

A technology for reconstituting tobacco leaves and nitrates, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of waste of water resources, high maintenance costs, loss of effective components, etc., to avoid discharge, improve comprehensive utilization, and reduce processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

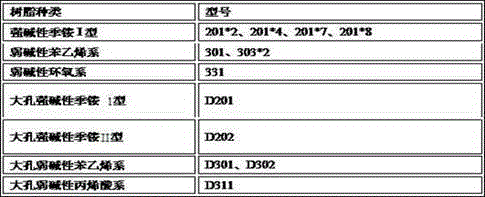

[0032] (1) Take 100g of tobacco stem extract with a concentration of 8.31% and put it into a 500mg special flask. It is detected that the nitrate content in it is 0.21% (the nitrate content is 2.53% on an absolute dry basis). Add 20g of pretreated 201 *2 Anion exchange resin (its water content is 51.2%), stirred at room temperature for 5 minutes;

[0033] (2) Use a 100-mesh sieve to filter out the liquid part and keep the resin in the bottle. Add 25g of clear water to the bottle twice to rinse twice, filter the rinse solution and combine with the above-mentioned primary solution to obtain a total of 128g of liquid;

[0034] (3) Take a small amount of liquid and fully dry it in an oven. The measured concentration (solid content) is 6.12%; the nitrate ion content in the liquid part is also detected to be 0.003%. The calculated yield of the active components of the treated tobacco was 94.3%, and the relative removal rate of nitrate ions was 98.1%.

Embodiment 2

[0036] (1) Take 100g of tobacco stem extract with a concentration of 8.31% and put it into a 500mg special flask. It is detected that the nitrate content in it is 0.21% (the nitrate content is 2.53% on an absolute dry basis). Add 20g of pretreated 303 *2 Anion exchange resin (its water content is 49.3%), stirred at room temperature for 5 minutes;

[0037] (2) Use a 100-mesh sieve to filter out the liquid part and keep the resin in the bottle. Add 25g of water to the bottle twice to rinse twice, filter the rinse solution and combine with the above-mentioned first solution to obtain a total of 127g of liquid;

[0038] (3) Take a small amount of liquid and fully dry it in an oven. The measured concentration (solid content) is 6.12%; the nitrate ion content in the liquid part is also detected to be 0.032%. The calculated yield of the active components of the treated tobacco was 92.5%, and the relative removal rate of nitrate ions was 79.1%.

Embodiment 3

[0040] (1) Take 100g of tobacco stem extract with a concentration of 8.31% and put it into a 500mg special flask. It is detected that the nitrate content in it is 0.21% (the nitrate content is 2.53% on a dry basis). Add 20g of pretreated 331 Anion exchange resin (its water content is 47.6%), stirred at room temperature for 5 minutes;

[0041] (2) Use a 100-mesh sieve to filter out the liquid part and keep the resin in the bottle. Add 25g of clear water to the bottle twice and rinse twice, filter the rinse solution and combine with the above-mentioned primary solution to obtain a total of 125g of liquid;

[0042] (3) Take a small amount of liquid and fully dry it in an oven. The measured concentration (solid content) is 6.25%; the nitrate ion content in the liquid part is also detected to be 0.010%. The calculated yield of the active components of the treated tobacco was 93.0%, and the relative removal rate of nitrate ion was >93.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com