Spot welding connection modeling method and system for automobile body-in-white

A body-in-white, connection-building technology, applied in welding equipment, manufacturing computing systems, resistance welding equipment, etc., can solve the problems of inability to guarantee the accuracy of CAE simulation analysis, incorrect connection of CAE solder joints, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]In order to make the purpose, features and advantages of the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Several embodiments of the invention are shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

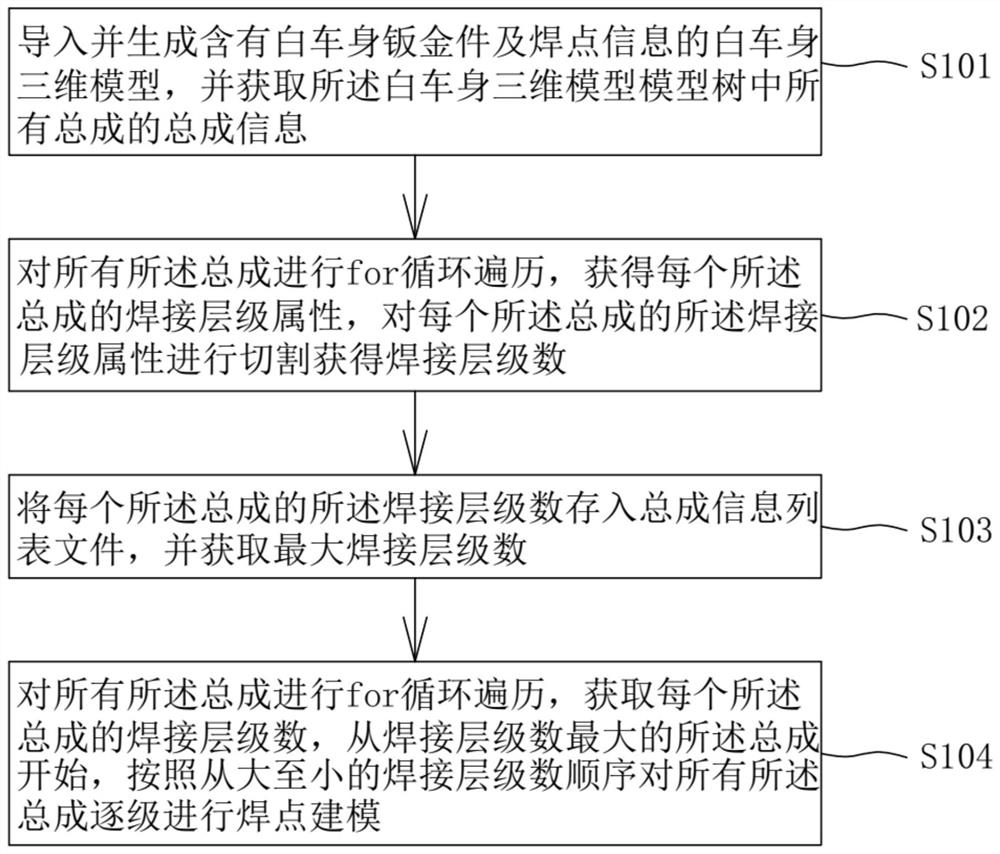

[0043] Please refer to figure 1 , The first embodiment of the present invention provides a spot welding connection modeling method of an automobile body-in-white, including steps S101-S104.

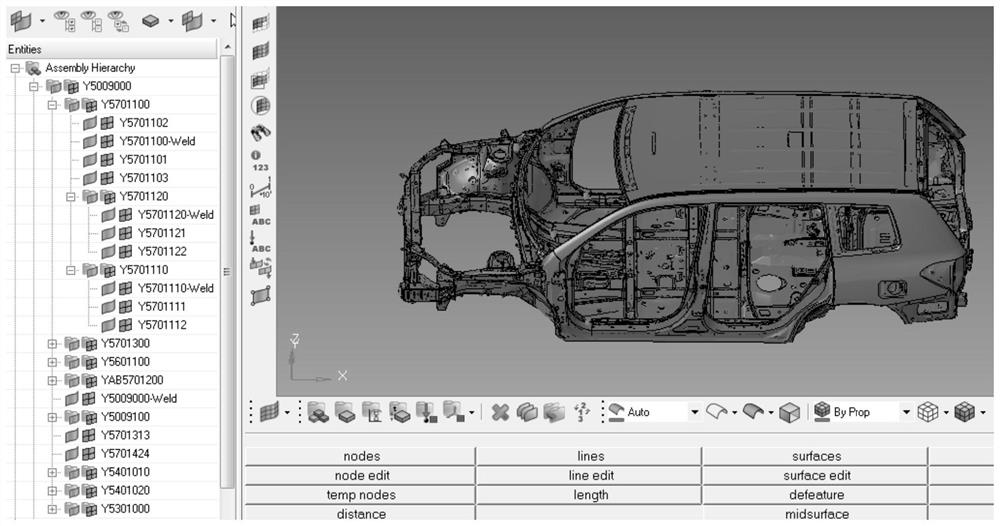

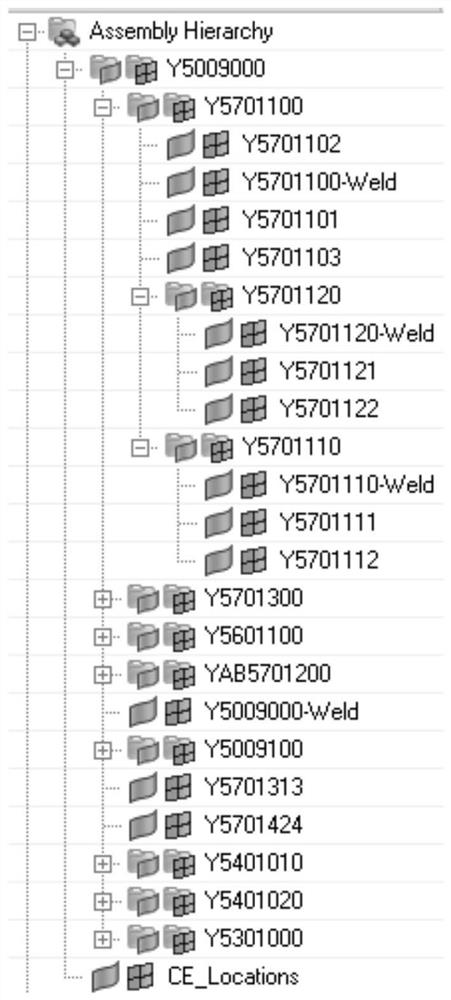

[0044] S101. Import and generate a BIW three-dimensional model including information on sheet metal parts and welding points of the BIW, and acquire assembly information of all assemblies in the BIW three-dimensional model mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com