Nuclear power plant equipment supervision and predictive health management method

A health management and predictive technology, applied in forecasting, data processing applications, instruments, etc., can solve the problems of failure to effectively evaluate equipment status, lack of scientific equipment supervision and management methods, lack of nuclear power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

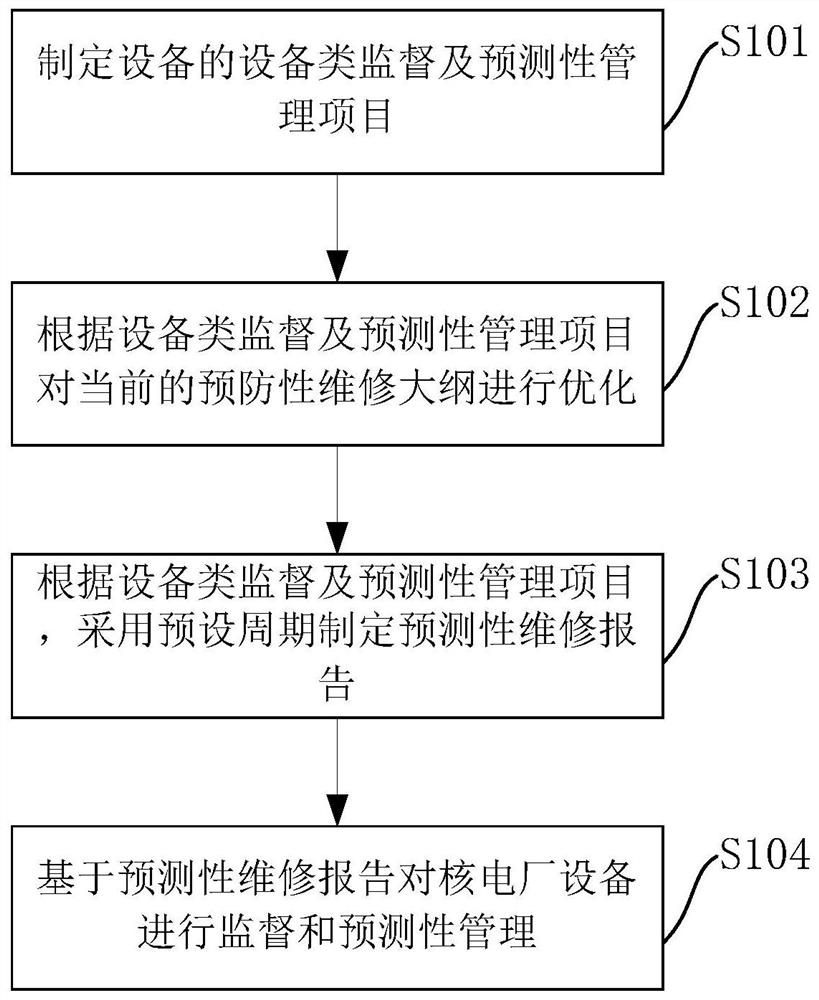

[0045]referencefigure 1,figure 1The flow schematic of the flowchart of an alternative embodiment of the nuclear power plant equipment for nuclear power plants provided by the present invention. The apparatus referred to in the present invention is a device that is classified according to the type or type of the device, ie the present invention is a supervision and predictive management of various types or the same type of equipment in nuclear power plants.

[0046]Such asfigure 1As shown, the nuclear power plant supervision and predictive health management methods include:

[0047]Step S101, the device's device-type supervision and predictive management items are set.

[0048]Among them, it can include: According to the device's device supervision and predictive management proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com