Nano-carbon composite lithium metal negative electrode and preparation method thereof

A metal negative electrode and composite lithium technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of huge volume change and high mass fraction of lithium metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a nano-carbon composite lithium metal negative electrode, comprising the following steps: S1. performing graphitization treatment on a nano-carbon material to obtain a highly graphitized nano-carbon material; S2. making the highly graphitized nano-carbon material obtained in step S1 The carbon material and the molten liquid lithium are fully mixed and reacted, followed by cooling treatment to obtain a nano-carbon composite lithium metal negative electrode.

[0025] The inventors found that in the preparation process of the nano-carbon composite lithium metal negative electrode in the prior art, other elements are basically introduced into the modification process of the nano-carbon, so that the content of metal lithium in the negative electrode material is low, reducing the lithium metal negative electrode. It is difficult to give full play to the high specific capacity of the lithium metal negative electrode. At the same tim...

Embodiment 1

[0038] This embodiment provides a method for preparing a graphene composite lithium metal negative electrode, comprising the following steps:

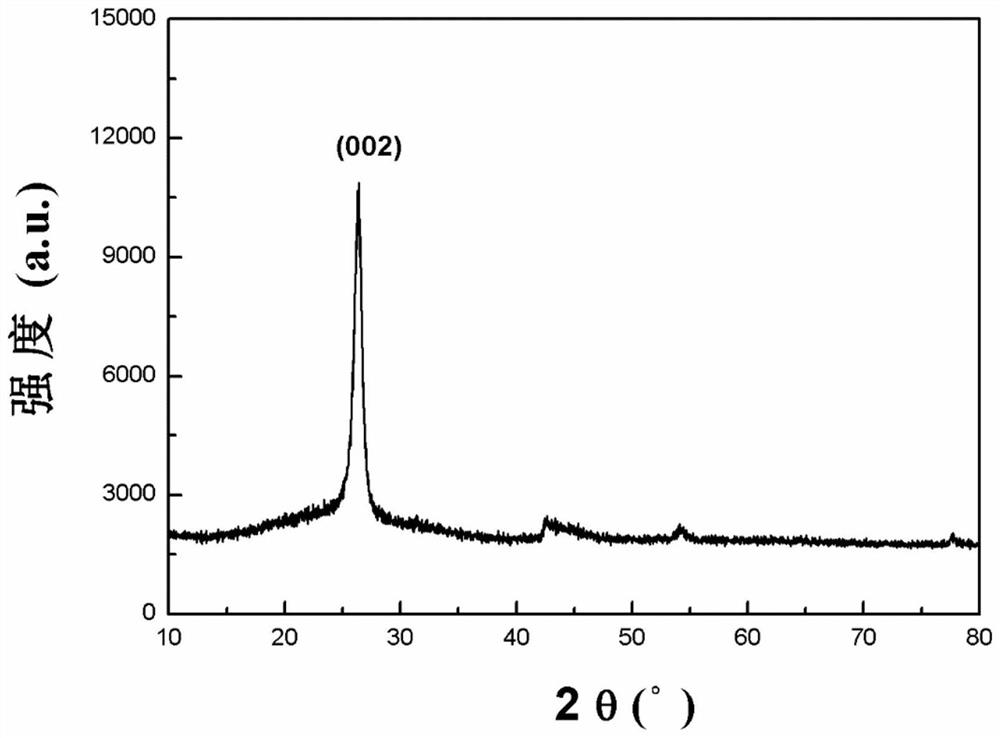

[0039] S1. Treat graphene at a constant temperature of 2000°C for 60 minutes to obtain highly graphitized graphene; the XRD spectrum of this highly graphitized graphene is as attached figure 1 As shown, in its XRD spectrum, 2θ appears the characteristic peak of sharp graphite (002) near the 26 ° position, and the degree of graphitization is 92.9%, and in the Raman spectrum, I D : I G = 0.15.

[0040] S2. Under the Ar atmosphere condition, add the highly graphitized graphene powder obtained in step S1 into molten liquid lithium at 200°C, and the amount of highly graphitized graphene added is 20%wt; subsequently, after stirring the mixture continuously for 30 minutes A molten lithium / highly graphitized graphene mixture is obtained; the stirred molten lithium / highly graphitized graphene mixture is coated on a copper foil current collect...

Embodiment 2

[0044] This embodiment provides a method for preparing a graphene composite lithium metal negative electrode, comprising the following steps:

[0045] S1. Graphene is treated at a constant temperature of 1500° C. for 100 minutes to obtain highly graphitized graphene; in the XRD spectrum of this highly graphitized graphene, a sharp characteristic peak of graphite (002) appears at 2θ near the position of 26°, graphite The degree of conversion is 89.3%, and in the Raman spectrum I D : I G = 0.3.

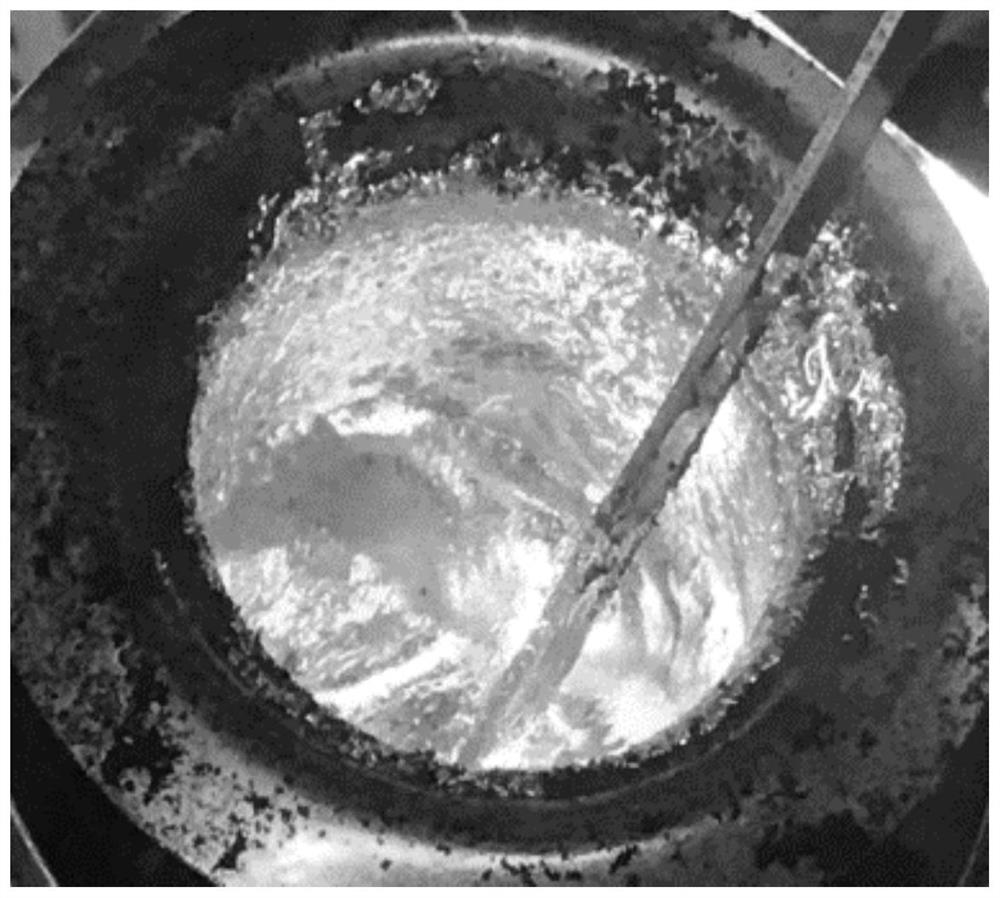

[0046] S2. Under Ar atmosphere conditions, add the highly graphitized graphene powder obtained in step S1 into molten liquid lithium at 300°C, and the amount of highly graphitized graphene added is 25%wt; subsequently, after stirring the mixture continuously for 50 minutes , the liquid lithium is completely infiltrated into the skeleton of the highly graphitized graphene, presenting a uniform silver-white mixed liquid to obtain a molten lithium / highly graphitized graphene mixture; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com