Titanium oxide@C hollow composite framework, preparation method and application thereof

A titanium oxide and hollow technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, electrochemical generator, etc., can solve the problems of uncontrollable dendrites, large volume effect, low Coulombic efficiency, etc., and achieve strong lithium affinity, Suppresses shuttle and improves the effect of volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

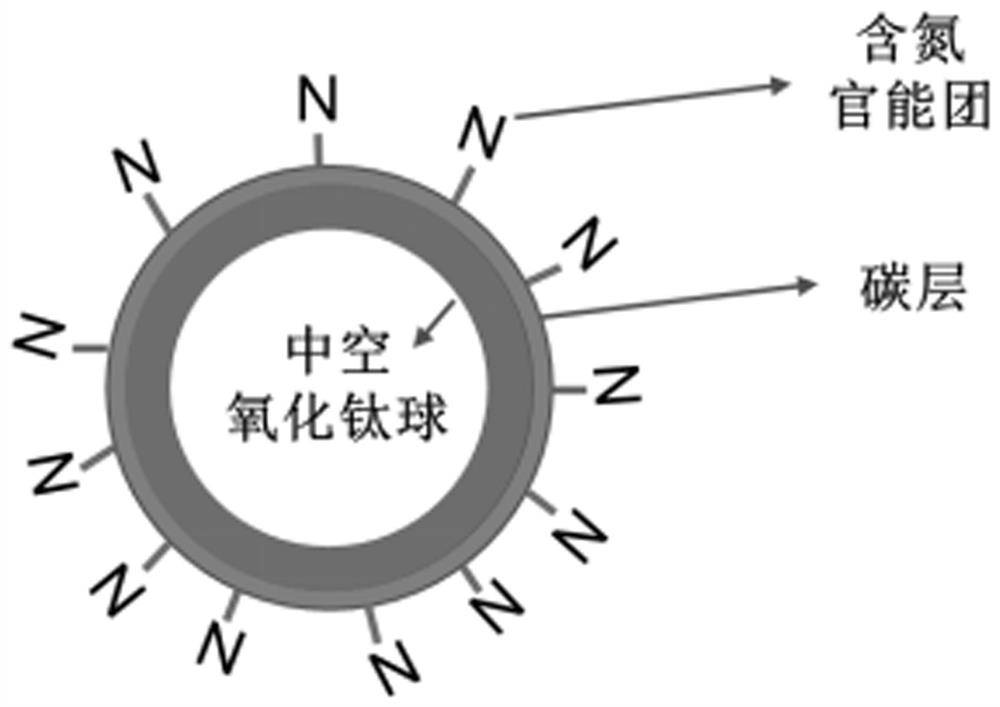

Embodiment 1

[0064] Put 0.1g of PS balls with an average diameter of 400nm in 35ml of ethanol solvent, add 0.35g of hexadecylamine and 0.9ml of ammonia water, stir for 10min, then add 0.3ml of tetraisopropyl titanate, react for 2h, filter and wash to obtain PS @TiO 2 . Add 150ml of 0.01mol / L trismethylol-aminomethane and ultrasonically disperse, continue to add 0.08g of dopamine, adjust the pH to 8.5, stir for 12h, filter and wash, and dry at 70°C for 8h. Transfer to a tube furnace under a mixed flow of hydrogen and argon at 5°C / min and heat up to 900°C for 4 hours to obtain nitrogen-doped TiO 2 @C Hollow composite skeleton material.

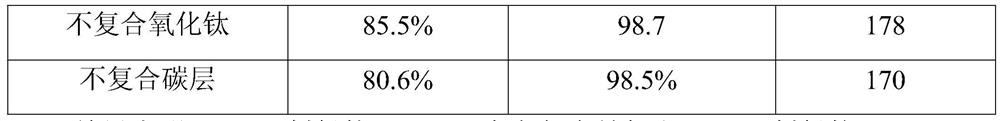

[0065] From the experimental results, it can be seen that TiO 2 @C The surface of the hollow composite skeleton is evenly distributed with N elements, and the proportion of N elements is 10at.%. TiO is on the composite skeleton 2 The wall thickness of the hollow shell is 20nm, the cavity volume accounts for 70%, the shell is uniform and complete, the thi...

Embodiment 2

[0079] Put 0.1g of PS balls with an average diameter of 400nm in 35ml of ethanol solvent, add 0.35g of hexadecylamine and 0.9ml of ammonia water, stir for 10min, then add 0.35ml of tetraisopropyl titanate, react for 2h, filter and wash to obtain PS @TiO 2 . Add 150ml of 0.01mol / L trismethylol-aminomethane and ultrasonically disperse, continue to add 0.08g of dopamine, adjust the pH to 8.5, stir for 12h, filter and wash, and dry at 70°C for 8h. Transfer to a tube furnace under a mixed flow of hydrogen and argon at 5°C / min and heat up to 900°C for 4 hours to obtain nitrogen-doped TiO 2 @C Hollow composite skeleton material. From the experimental results, it can be seen that TiO 2 @C The surface of the hollow composite skeleton is evenly distributed with N elements, and the proportion of N elements is 10.2 at.%. TiO is on the composite skeleton 2 The wall thickness of the hollow shell is 25nm, the cavity volume accounts for 68%, the shell is uniform and complete, the thicknes...

Embodiment 3

[0087] Put 0.1g of PS balls with an average diameter of 400nm in 35ml of ethanol solvent, add 0.35g of hexadecylamine and 0.9ml of ammonia water, stir for 10min, then add 0.3ml of tetraisopropyl titanate, react for 2h, filter and wash to obtain PS @TiO 2 . Add 150ml of 0.01mol / L trismethylol-aminomethane and ultrasonically disperse, continue to add 0.09g of dopamine, adjust the pH to 8.5, stir for 12h, filter and wash, and dry at 70°C for 8h. Transfer to a tube furnace under a mixed flow of hydrogen and argon at 5°C / min and heat up to 900°C for 4 hours to obtain nitrogen-doped TiO 2 @C Hollow composite skeleton material. From the experimental results, it can be seen that TiO 2 @C The surface of the hollow composite skeleton is evenly distributed with N elements, and the proportion of N elements is 10.5 at.%, and TiO is on the composite skeleton 2 The wall thickness of the hollow shell is 20nm, the cavity volume accounts for 70%, the shell is uniform and complete, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com