Bilateral short primary synchronous reluctance linear motor

A technology of synchronous reluctance and linear motors, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of low efficiency and power factor due to end effects, large thrust fluctuations, limited speed range of linear induction motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

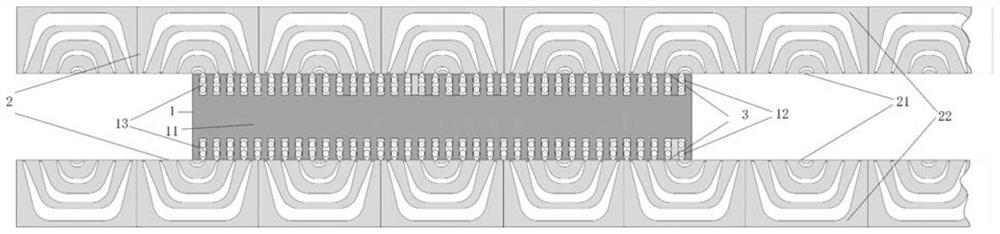

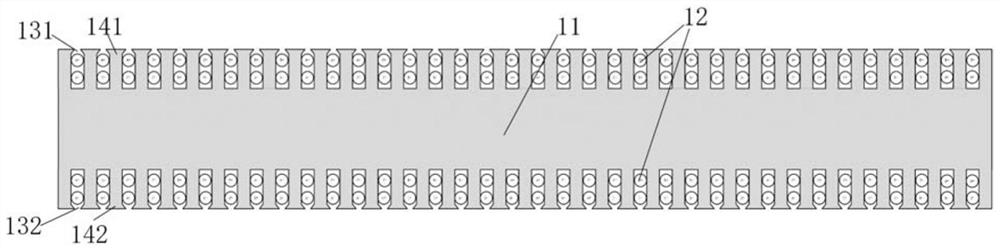

[0030] Such as figure 1 As shown, this embodiment provides a bilateral short primary synchronous reluctance linear motor, including two symmetrically arranged long secondary stators 2 and a short primary mover 1 installed between the long secondary stators 2 and capable of reciprocating motion , there is a gap 3 between the short primary mover 1 and the long secondary stator 2 on both sides, the short primary mover 1 includes a primary iron core 11 and an armature winding 12, and the primary iron core 11 is close to the surface of the long secondary stator Both sides of 21 are provided with cogged structures, and the armature winding 12 is arranged in the cogged structures. The long secondary stator 2 includes several magnetic pole modules 22 sequentially installed along the moving direction of the short primary mover 1 .

[0031] In the present invention, cogging structures and armature windings 12 are respectively arranged on both sides of the short primary mover 1, and lon...

Embodiment 2

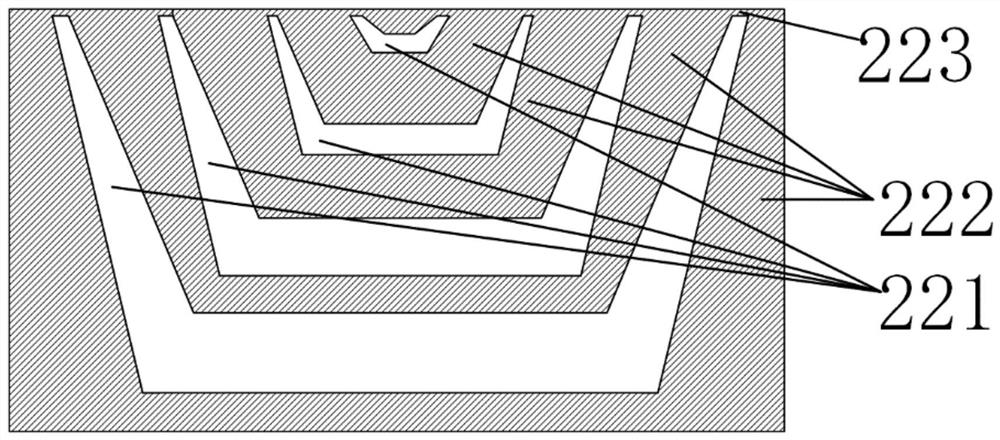

[0035] This embodiment provides a bilateral short-primary synchronous reluctance linear motor. The overall structure of the motor is basically the same as that of Embodiment 1. The difference is that the magnetic pole module 22 in this embodiment is as Figure 4 As shown, the outer contour of the magnetic barrier 221 in the magnetic pole module 22 is a streamline shape formed by a spline curve, and the rest are the same as in the first embodiment. The main difference between embodiment 1 and embodiment 2 is that the corresponding magnetic permeability ratio and the direction of the magnetic force lines near the outer contour of the magnetic barrier 221 are different, resulting in differences in the salient pole ratio and torque density of the motor, which need to be considered comprehensively for a long time The mechanical strength of the secondary stator 2 is chosen as a trade-off.

Embodiment 3

[0037] This embodiment provides a bilateral short-primary synchronous reluctance linear motor. The overall structure of the motor is basically the same as that of Embodiment 1. The difference is that the magnetic pole module 22 in this embodiment is as Figure 5As shown, the magnetic pole module 22 includes a non-iron rib magnetic pole module 22, and the non-iron rib magnetic pole module 22 includes a magnetic barrier 221, a magnetic bridge 222 and a non-magnetic filling material, and a plurality of magnetic barriers 221 and magnetic bridges 222 are arranged in a staggered manner , the non-magnetic filling material is filled in the magnetic barrier 221 to connect a plurality of magnetic bridges 222 into one body, and the outer contour of the magnetic barrier 221 is a multi-linear shape composed of straight line segments. The rest are the same as in Embodiment 1. The main difference between Embodiment 1 and Embodiment 3 is: from the perspective of the electromagnetic characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com