Green walnut peeling equipment

A green walnut and equipment technology, applied in the field of green walnut peeling equipment, can solve the problems of incomplete peeling, uneven force on the contact surface and non-contact surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] The first preferred embodiment:

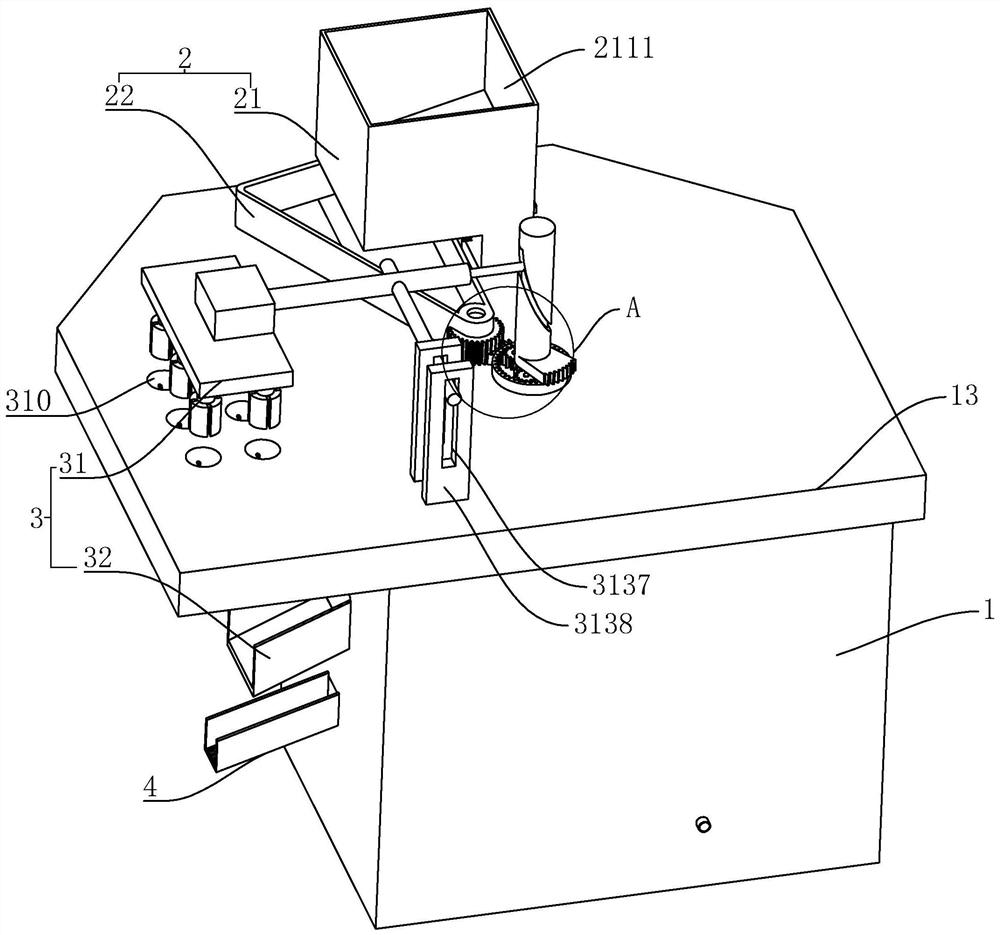

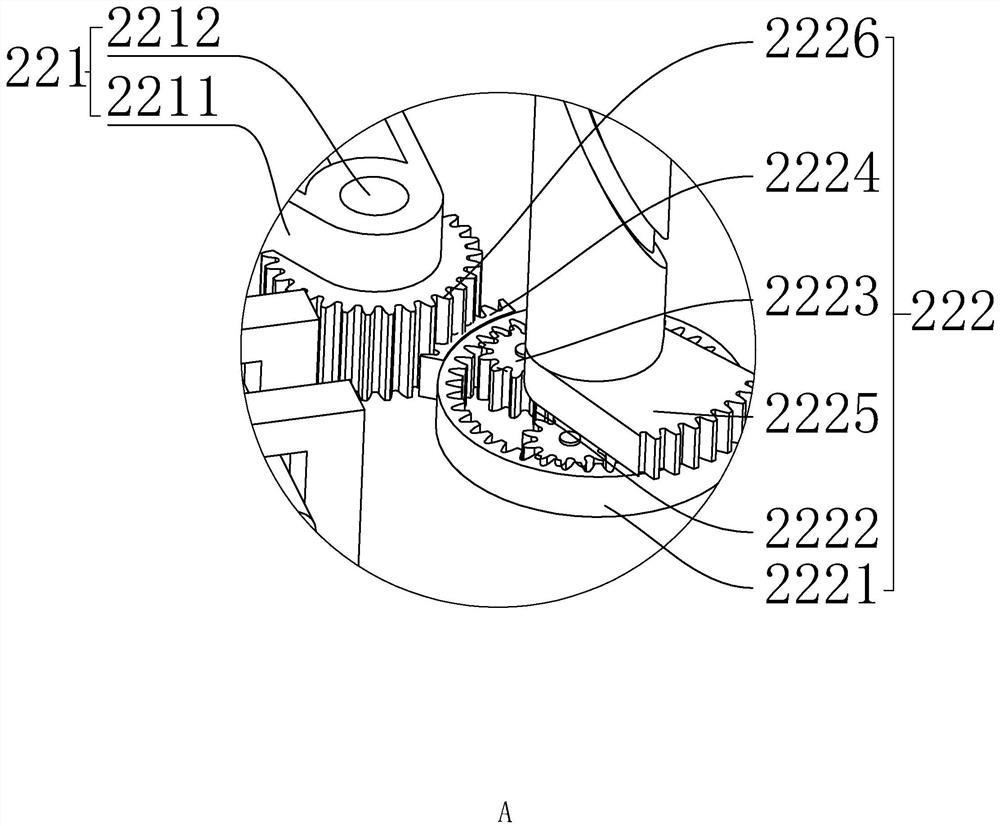

[0035] A kind of green walnut peeling equipment, such as figure 1 As shown, the casing 1 is included, the bottom of the casing 1 is provided with a driving device 11, and the driving device 11 is provided with a driving shaft 12; The lower part of the silo 2111 is provided with a cylindrical hole 310 connected to the casing 1 below the platform 13 . The platform 13 is provided with a transport device 2 for transporting green walnuts from the storage bin 2111 to several cylindrical holes 310 . The conveying device 2 includes an unloading mechanism 21 that enables the storage bin 2111 to unload material after being squeezed by an external force, and a material conveying mechanism 22 that reciprocates for quantitative conveyance.

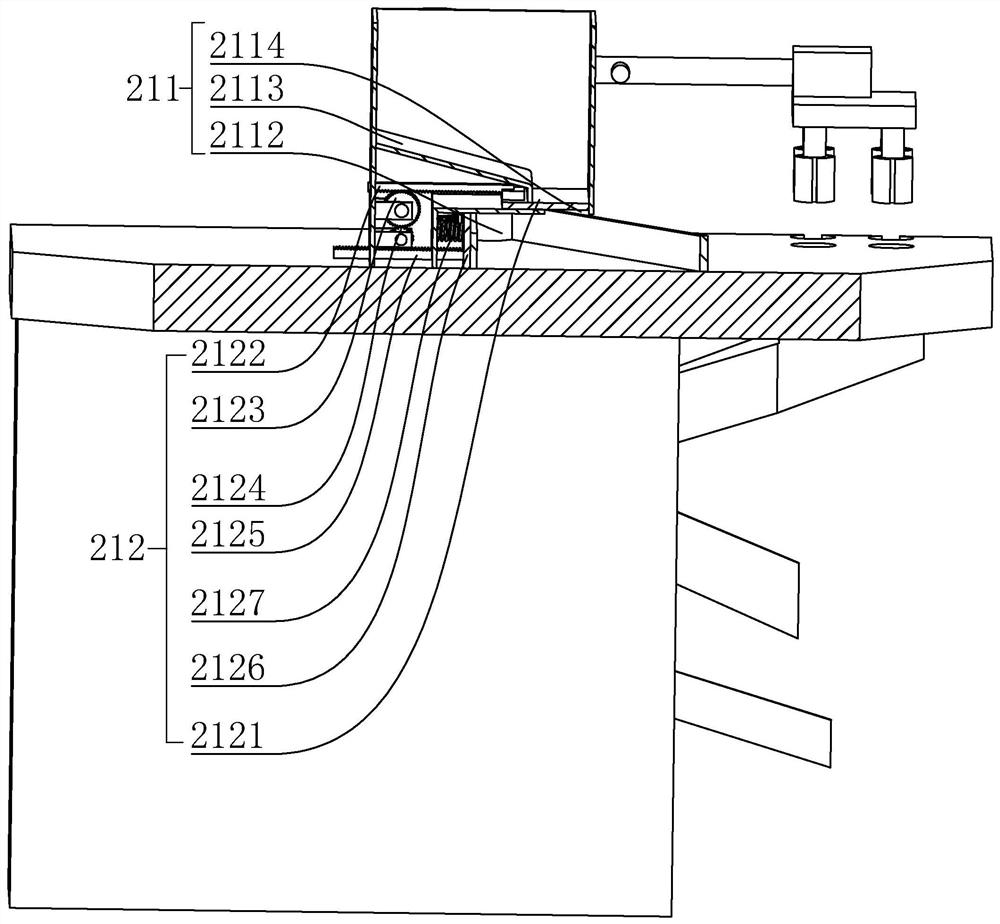

[0036] Such as image 3 As shown, the unloading mechanism 21 includes a storage assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com