Laminating roller

A lamination roller, lamination machine technology, applied in the direction of lamination, lamination device, control lamination, etc., to achieve the effects of prolonging service life, improving heating control, and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

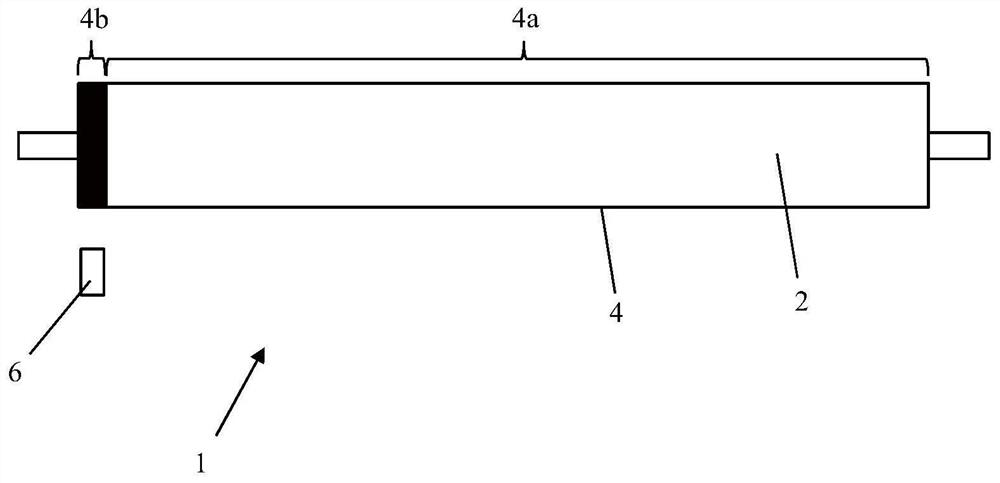

[0017] The laminator 1 comprises heated lamination rolls 2 for bringing into contact a workpiece, such as a sheet to be laminated, by bringing a film of laminate material into adhesive contact with the surface of the sheet.

[0018] The cylindrical outer surface 4 of the laminating roll 2 comprises a wear-resistant and highly reflective chrome-plated surface region 4a. A non-reflective (or matte) surface region 4b is provided at one axial end of the lamination roll 2 . The non-reflective surface region 4b may comprise a strip or band of suitable non-reflective material arranged in an annular groove or channel (not shown) in the outer surface of the laminating roll 2 so that the non-reflective material The outer surface is flush with the outer surface of the chromed surface area 4a. The strip or strip of non-reflective material is about 1-2 centimeters (cm) wide. Alternatively, the non-reflective surface region 4b may comprise a thin layer or coating of a suitable non-reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com