Continuous image-text splicing method for ink-jet printer

An inkjet printer, graphics and text technology, applied to the printing device, printing and other directions, can solve the problems of easy deviation of the paper feeding device, affect the visual effect, and the printing image deviates from the printing position, etc., to improve the printing resolution and the vividness of the color , improve printing quality, and ensure the effect of inkjet printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

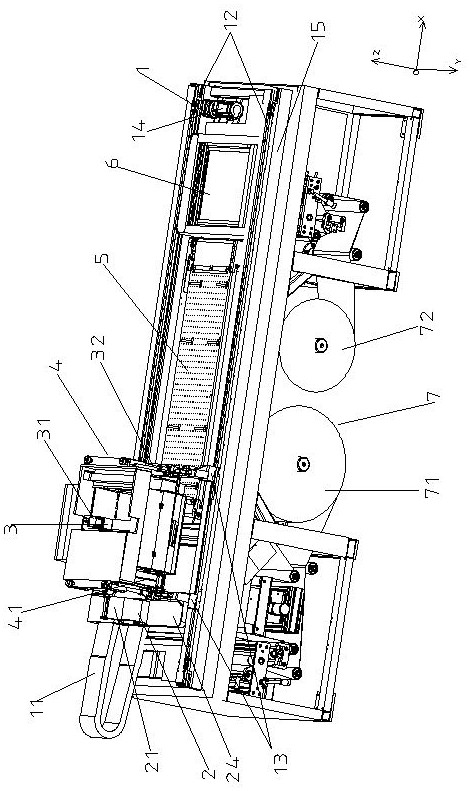

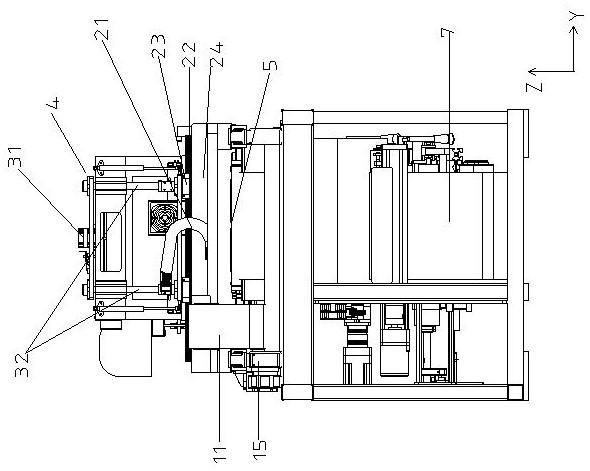

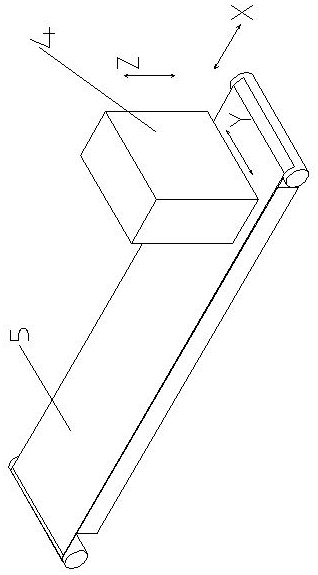

Image

Examples

Embodiment 1

[0049] In this embodiment, the detection device 42 uses a sensor. The sensor is triggered when it passes the mark on the lower medium during the movement process and feeds back the position information here. The software uses the actual position information detected by the sensor to perform the first inkjet printing process. Error correction in the direction (X-axis direction).

[0050] first according to Figure 7 The detection of the logo by the sensor is described. The color of the logo needs to be different from the color of the printing medium. Here, the black rectangle logo is still taken as an example for illustration. During the movement of the printing carriage in the first direction (X-axis direction), the sensor installed on the left end of the printing carriage detects the mark on the medium below. When it reaches the start position of the edge of the black rectangle mark, the sensor is triggered, feedbacks the rising edge signal and remains high. level until the ...

Embodiment 2

[0056] In this embodiment, the detection device 42 uses a camera, and the software pre-calculates the position information of the trigger signal for controlling the camera to take pictures. After receiving the trigger signal, take a photo of the logo below, and the software will perform image recognition on the photo taken, calculate the actual location parameters of the logo, and feed back the location parameters to the control system to control the inkjet corresponding to the nozzle. This detection method, Errors such as stretching or angular deflection in the first direction (X-axis direction), second direction (Y-axis direction), and first direction (X-axis direction) can be corrected for the printed image.

[0057] The following is based on Figure 10 Describe in detail the motion process of the printer detected by the camera. When the media on each table starts printing, the printing carriage is located at the initial end on the right side of the first direction (X-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com