Semi-automatic data collecting and recording system of rolling and inspecting machine

A technology of data acquisition and recording system, which is applied in the direction of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, low efficiency, etc., and achieve convenient post-processing, high efficiency, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

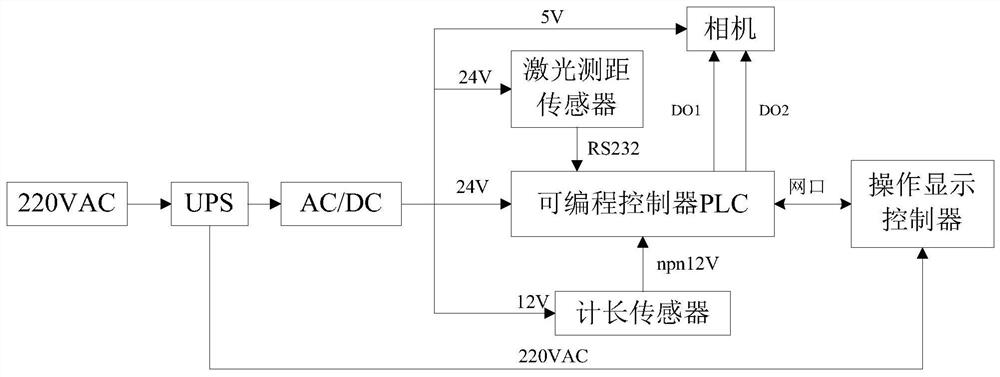

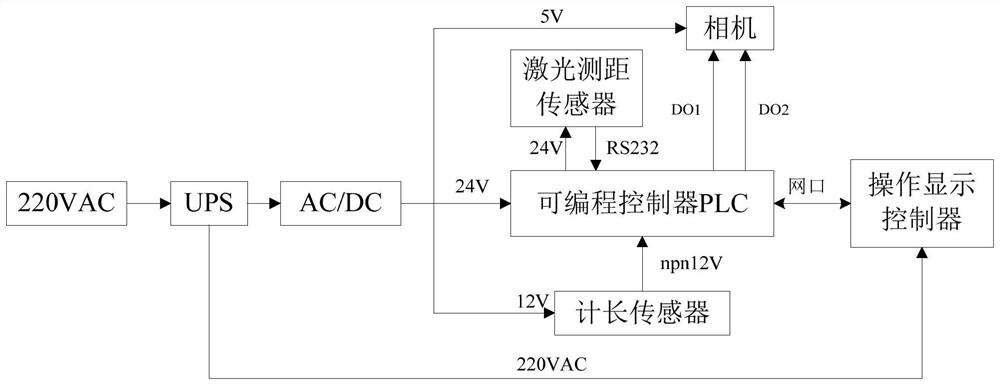

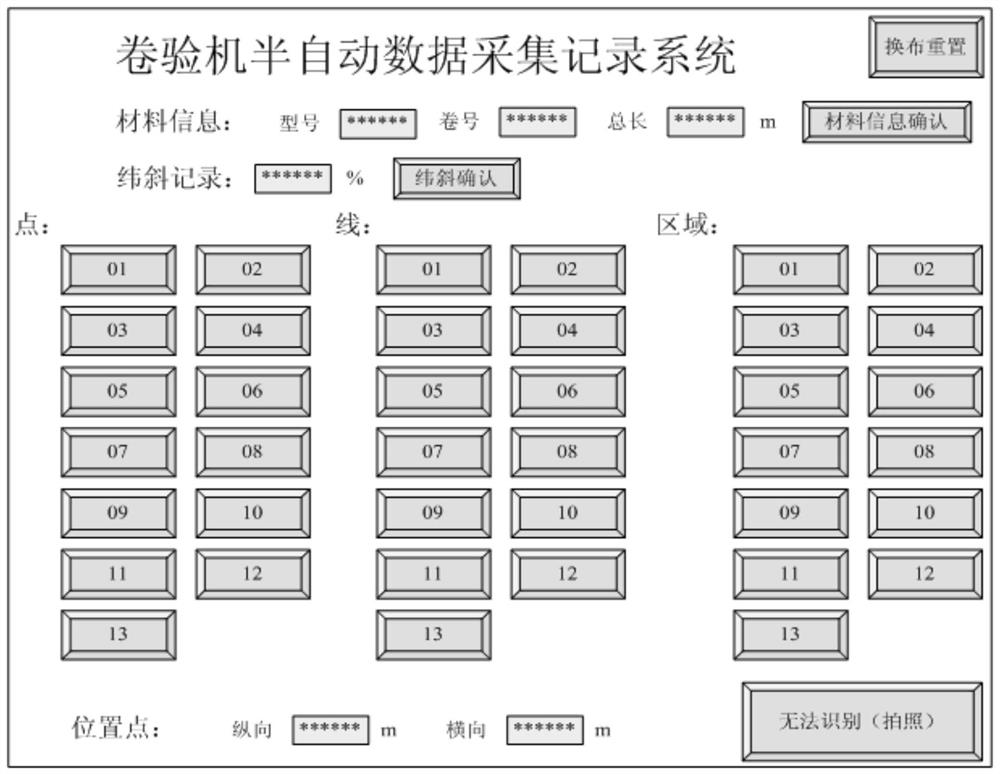

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0033] For the data recording and processing method of the traditional roll inspection machine, because it is completely operated by the staff, it leads to time-consuming, labor-intensive, and low efficiency problems. In addition, although an automatic roll inspection machine with good performance is equipped with an electronic defect detection device, the cost of the automatic roll inspection machine is too high for small batch products, and the value is 2 million. It is used for electronic defect inspection of ordinary fabrics, and is not suitable for inspection of bladder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com