A kind of wall mortar for preventing radiation pollution

A radiation protection and mortar technology, applied in the field of mortar for walls, can solve the problems of delamination, segregation and sagging of radiation protection mortar, and achieve the effects of enhancing radiation protection performance, improving mixing properties, and preventing segregation and delamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

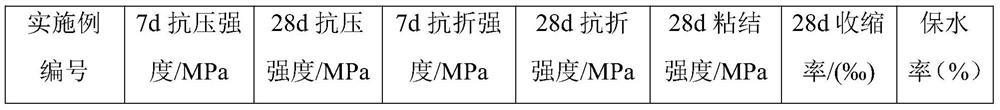

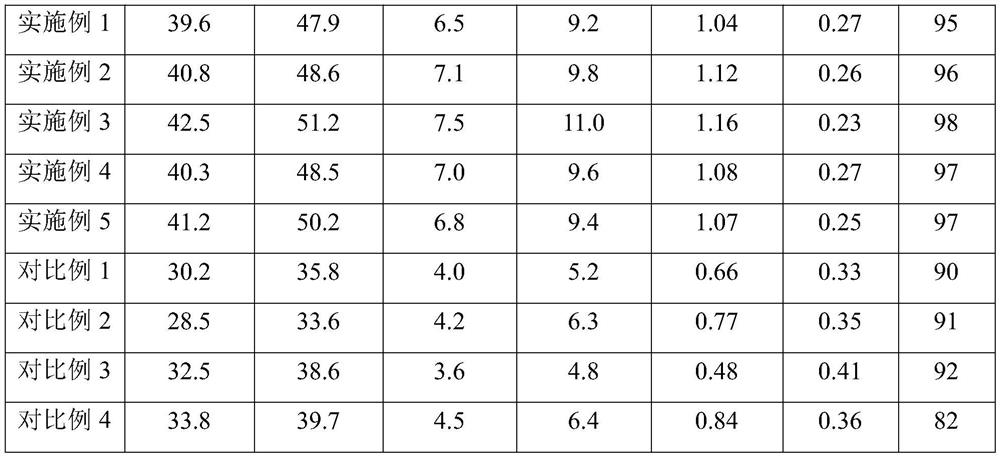

Examples

preparation example Construction

[0033] The preparation of modified polypropylene fibers and the preparation of modified glass fibers used in the following examples: the silane coupling agent is made into a diluent with a concentration of 1.5wt% with absolute ethanol, and then the polypropylene fibers and glass fibers are soaked In the diluent, after ultrasonic dispersion for 45min, take out, wash with ethanol and deionized water for several times, and dry to obtain modified polypropylene fibers and modified glass fibers.

[0034] The preparation of the graphene oxide modified carbon fiber that following embodiment adopts:

[0035] S1. Graphene oxide is prepared by the modified Hummer's method, and then the carbon fiber is subjected to surface oxidation treatment; the surface oxidation treatment of carbon fiber adopts conventional methods in the art.

[0036] S2. Amino group modification on carbon fiber surface:

[0037] Add the oxidized carbon fibers into deionized water and stir, adjust the pH to 5, add 1-...

Embodiment 1

[0041] This embodiment provides a kind of wall mortar for preventing radiation pollution, which is composed of the following components by weight: 50Kg of cement, 20Kg of fly ash, 20Kg of river sand, 8Kg of redispersible latex powder, and 65Kg of 20-mesh barite sand , 10Kg of 100-mesh barite powder, 8Kg of 250-mesh barite powder, 6Kg of modified composite fiber, 8Kg of nano-lead powder, 5Kg of starch ether, cellulose thickener (2-hydroxypropyl methylcellulose and carboxymethyl fiber) The elements are mixed according to the mass ratio of 1:1) 6Kg;

[0042] Described modified composite fiber comprises modified polypropylene fiber, graphene oxide modified carbon fiber and modified glass fiber; The mass ratio of described modified polypropylene fiber, graphene oxide modified carbon fiber, modified glass fiber is 4: 2:1, wherein the length of modified polypropylene fiber is 5mm, the length of graphene oxide modified carbon fiber is 2mm, and the length of modified glass fiber is 1mm...

Embodiment 2

[0044] This embodiment provides a kind of wall mortar for preventing radiation pollution, which is composed of the following components by weight: 70Kg of cement, 30Kg of fly ash, 30Kg of river sand, 10Kg of redispersible latex powder, and 75Kg of 50-mesh barite sand , 20Kg of 200-mesh barite powder, 15Kg of 400-mesh barite powder, 10Kg of modified composite fiber, 12Kg of nano-lead powder, 8Kg of starch ether, cellulose thickener (2-hydroxypropyl methylcellulose and carboxymethyl fiber The elements are mixed according to the mass ratio of 1:3) 10Kg;

[0045] Described modified composite fiber comprises modified polypropylene fiber, graphene oxide modified carbon fiber and modified glass fiber; The mass ratio of described modified polypropylene fiber, graphene oxide modified carbon fiber, modified glass fiber is 5: 3:1, wherein the length of modified polypropylene fiber is 10mm, the length of graphene oxide modified carbon fiber is 4mm, and the length of modified glass fiber i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap