Assembly column-beam frame and sleeve structure thereof

A prefabricated, column-beam technology, applied in building structures, buildings, etc., can solve the problems of unfavorable building industrialization development, existing problems in combination, and high requirements for joints, and achieve the effect of shortening construction period, improving bearing capacity, and assembling firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention, and should not limit the protection scope of the present invention with this.

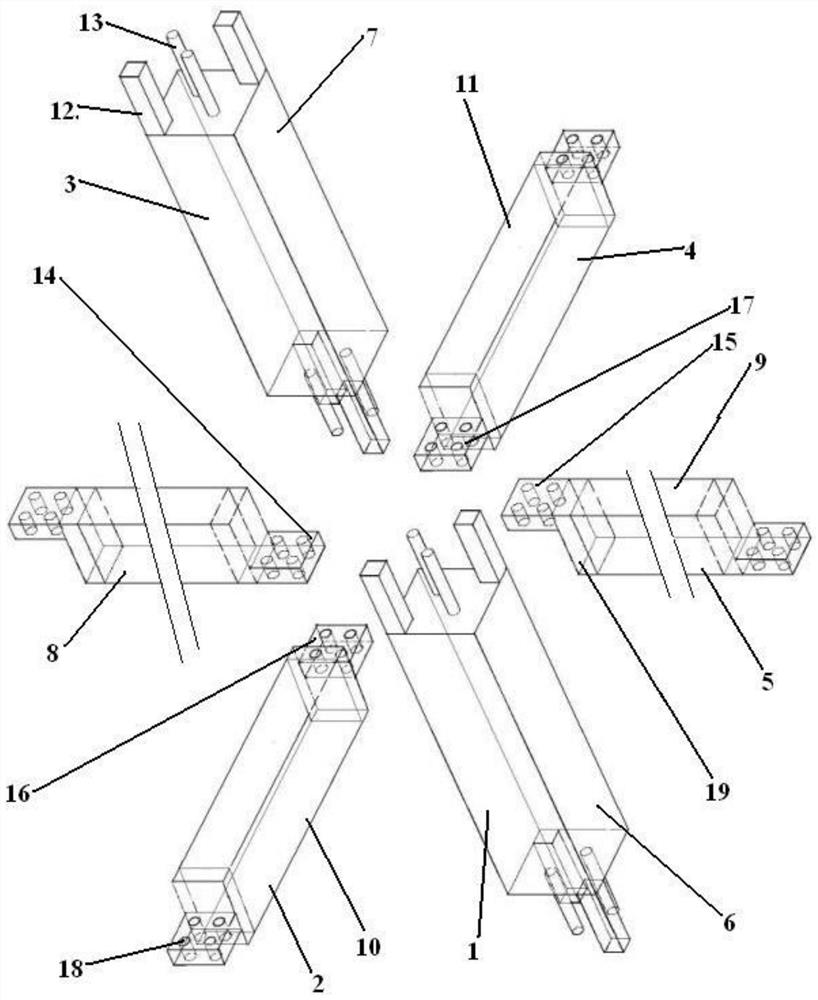

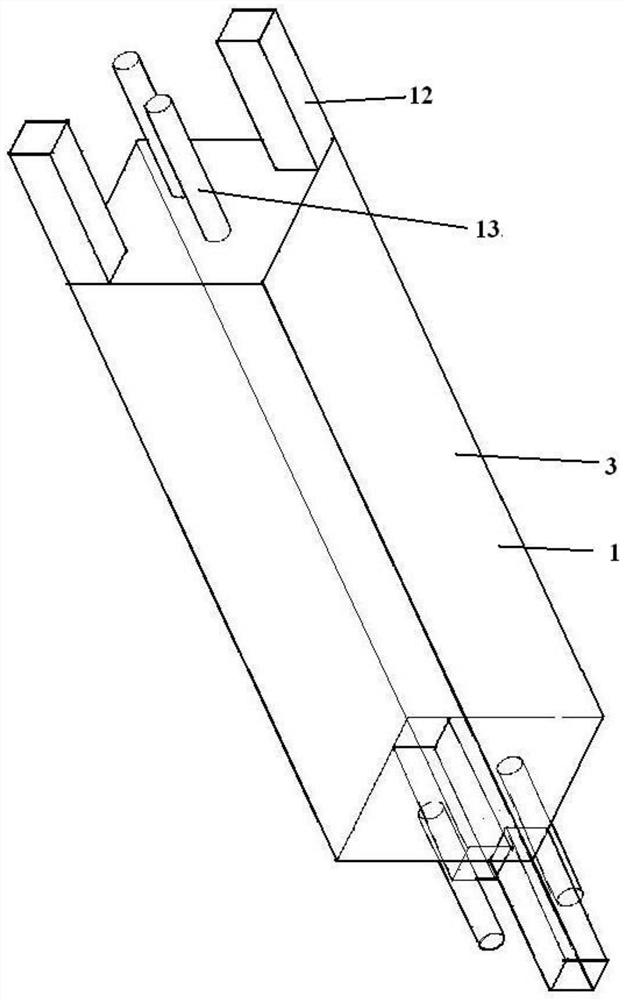

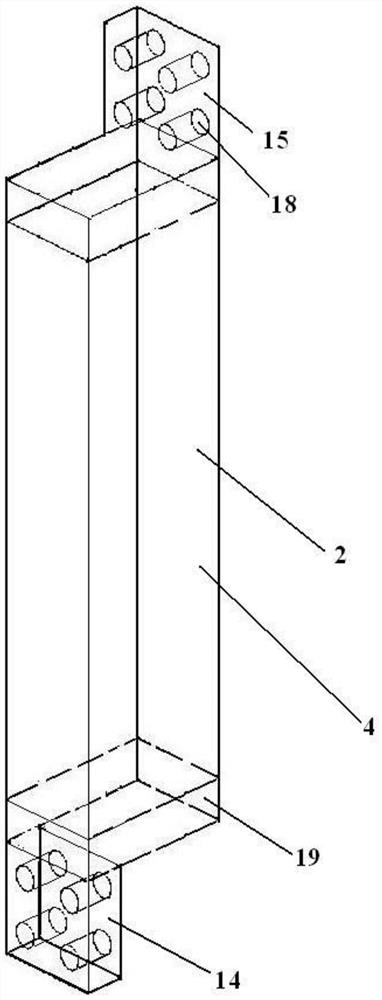

[0036] As shown in the figure, an assembled column-beam frame and its nested structure are produced, including a prefabricated structural column 1 and a prefabricated structural beam 2, the prefabricated structural column 1 includes a column 3, and the prefabricated structural beam 2 includes a crossbeam 4 and a prefabricated structural beam 2. The longitudinal beam 5; the column 3 can be divided into a lower column 6 and an upper column 7, the crossbeam 4 can be divided into a left beam 8 and a right beam 9, and the longitudinal beam 5 can be divided into a front beam 10 and a rear beam 11.

[0037] In this embodiment, the height of the column 3 is 4000mm, the cut surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com