A light steel floor structure of a prefabricated building

A light steel building and prefabricated technology, applied in building components, building structures, buildings, etc., can solve the problems of cumbersome construction process, long construction period and low construction efficiency of building structures, so as to shorten the construction period, improve construction efficiency, The effect of reducing construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

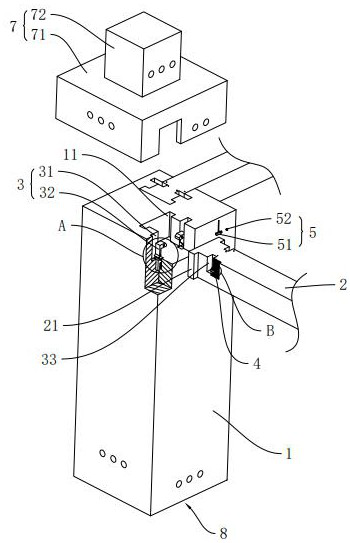

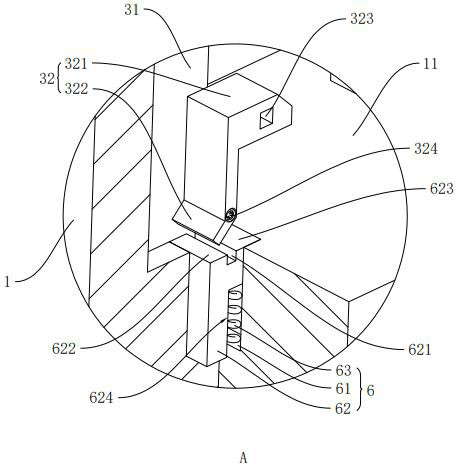

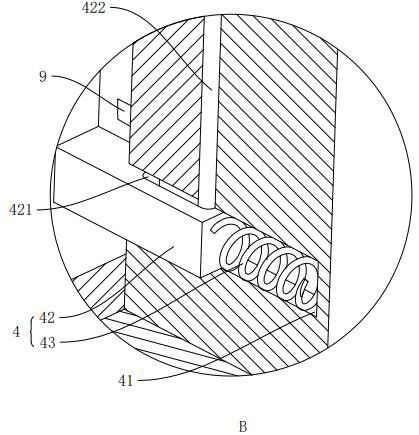

[0035] The following is attached Figure 1-3 The application is described in further detail.

[0036] The embodiment of this application discloses a light steel floor structure of a prefabricated building, refer to figure 1 , including girder 1 and joist 2, girder 1 is used for vertical load-bearing, joist 2 is used for lateral load-bearing, joist 2 and girder 1 are connected to each other to form a frame structure, and at the same time on joist 2 Pour the slab to form the planar structure of the floor.

[0037] Specifically, an assembly port 11 is provided on the support beam 1, and an assembly block 21 is integrally provided on the joist beam 2 at the same time. When building, the assembly block 21 on the joist beam 2 is aligned with the assembly port 11 on the support beam 1, And press the assembly block 21 into the assembly opening 11 from above the support beam 1 to form a lateral positioning between the support beam 1 and the joist 2 .

[0038] refer to figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com