Grading method suitable for soft rock tunnel deformation grade under ultrahigh ground stress effect

A technology of deformation grade and grading method, which is applied in the field of grade grading, can solve the problems that the large deformation of the surrounding rock is not consistent, can not take targeted measures, and the understanding of extrusive phyllite is insufficient, so as to achieve strong pertinence and adaptability The effect of wide range and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

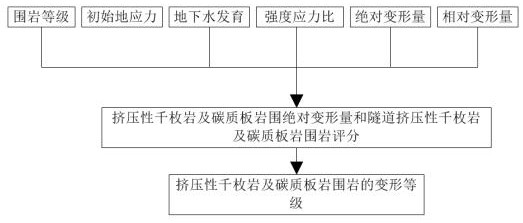

[0026] Such as figure 1 As shown, this embodiment provides a classification method suitable for the deformation grade of soft rock tunnels under the action of ultra-high ground stress, and the specific steps are as follows:

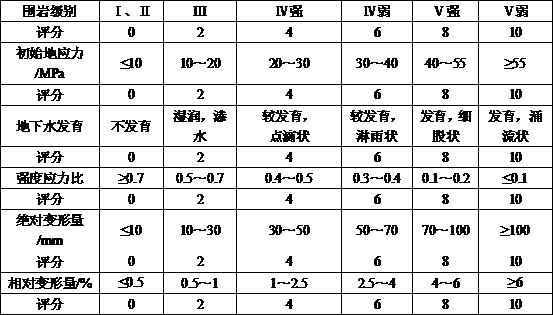

[0027] Firstly, according to the geological survey data, parameters of tunnel extrusive phyllite and carbonaceous slate surrounding rock are obtained. The tunnel extrusive phyllite and carbonaceous slate surrounding rock parameters include: tunnel extrusive phyllite and carbonaceous The grade of surrounding rock of slate, the initial in-situ stress of tunnel extruding phyllite and carbonaceous slate surrounding rock, the development sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com