Preparation method of camellia tea

A production method and technology of camellia tea, applied in the field of production of camellia tea, can solve the problems of poor energy conversion rate, unstable physical and chemical properties, etc., and achieve the effect of increasing the types of scented tea, simple and convenient production process, and uniform flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

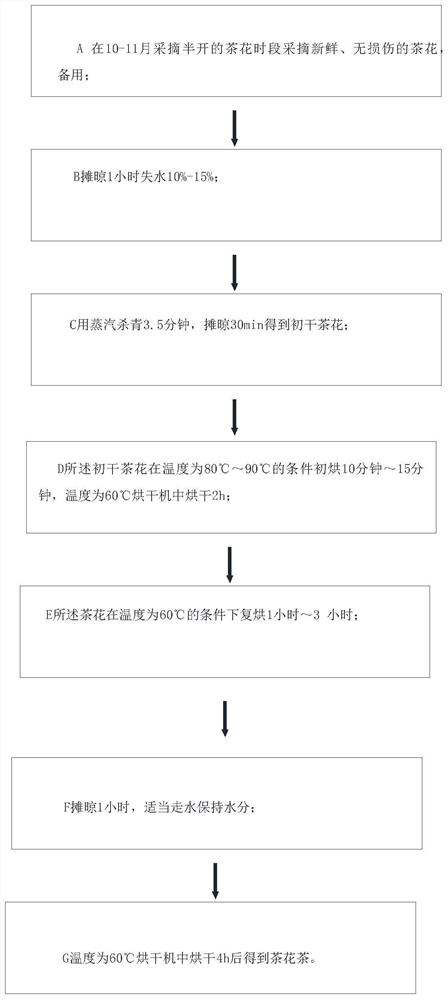

Image

Examples

Embodiment 2

[0026] Pick fresh, undamaged camellias during the period of picking half-opened camellias in October-November, and set them aside; B is aired for 1 hour to lose 12% of water; steam is used for 3.5 minutes, and aired for 30 minutes to obtain first-dried camellias, which are turned every 15 minutes , the steam finishing is done according to the ratio of the mass ratio of the camellia to water of 10:2, the initially dried camellia is initially dried at a temperature of 80° C. for 10 minutes, and the temperature is 60° C. in a dryer. 2h; the camellia was rebaked for 1 hour at a temperature of 70°C, and the thickness of the camellia piled up was 5cm; it was spread out for 1 hour, and the water was properly drained to maintain moisture; the temperature was 60°C and dried in a dryer for 4 hours to obtain tea scented tea.

Embodiment 3

[0028] Pick fresh, undamaged camellias during the period of picking half-opened camellias in October-November, and set aside; B spread out for 1 hour to lose 15% of water; use steam for 3.5 minutes, spread out for 30 minutes to get first-dried camellias, and turn it every 15 minutes , the steam finishing is done according to the ratio of the mass ratio of the camellia to water of 10:2, the initially dried camellia is initially dried at a temperature of 90°C for 15 minutes, and the temperature is 60°C in a dryer. 2h; the camellia was re-baked for 3 hours at a temperature of 70°C, and the thickness of the camellia piled up was 5cm; it was spread out for 1 hour, and the water was properly drained to maintain moisture; the temperature was 60°C and dried in a dryer for 4h to obtain tea scented tea.

[0029] Water running means that in the green leaf shaking process, the water in the stalks and veins of the green leaves is accelerated to the leaf surface through shaking the green le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com